Skin-core structure aerogel composite fibers as well as preparation method and application thereof

A composite fiber and skin-core structure technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of airgel failure, uniform mixing, etc., and achieve complete preservation, uniform composite, and excellent thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

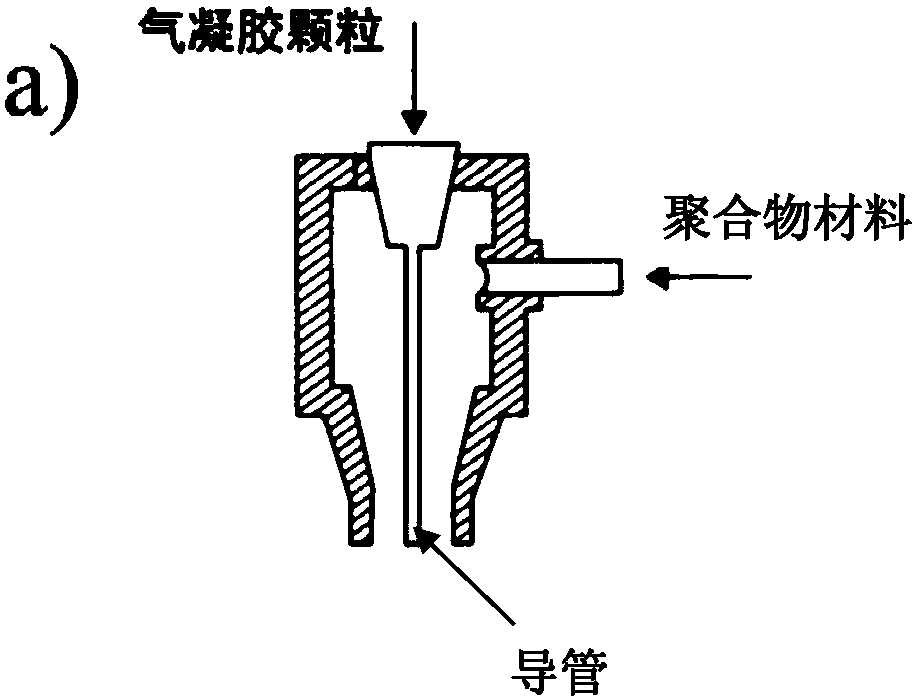

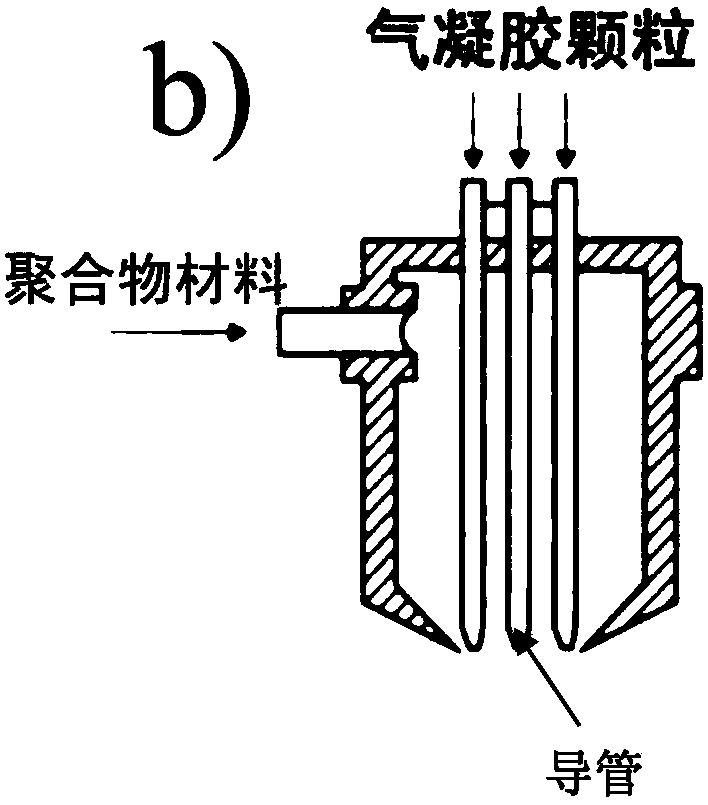

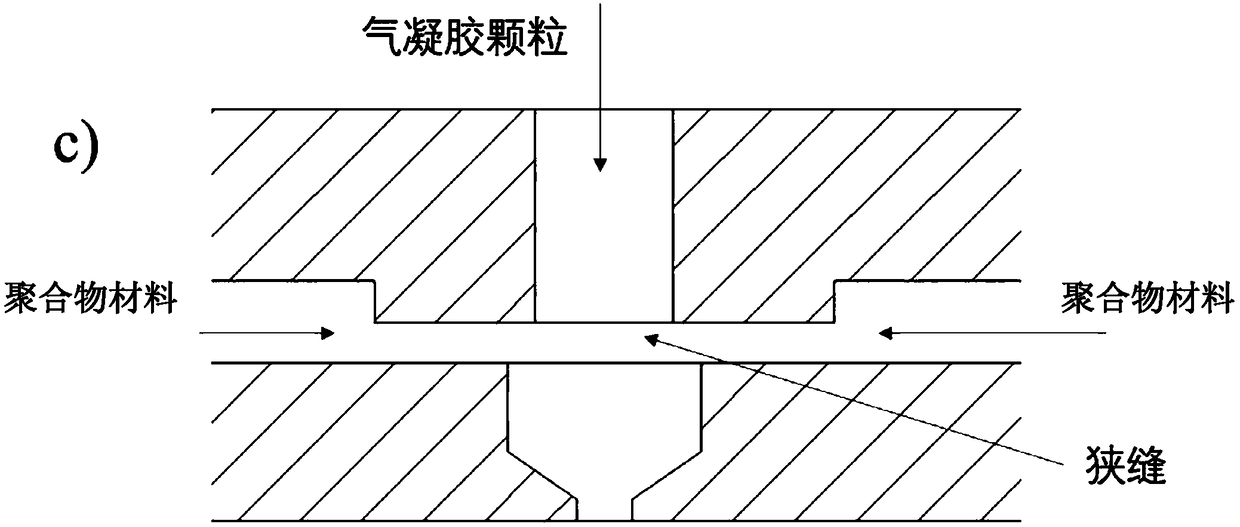

[0039] An aspect of the embodiments of the present invention provides a method for preparing a skin-core structure airgel composite fiber, which includes:

[0040] Using the skin-core composite spinning technology, the airgel particles and the polymer material in the molten state are compounded at the end of the spinneret hole, and the wire drawing and cooling are performed simultaneously to form a skin-core structure airgel composite fiber. The gel composite fiber includes a core comprising airgel particles, and a sheath covering the core, the sheath comprising a polymeric material.

[0041] In some embodiments, the preparation method includes: using skin-core composite spinning technology, extruding the airgel particles into the void formed by the polymer material to form a skin-core structure airgel composite fiber .

[0042] The principle of the preparation process of the present invention is: through the sheath-core composite spinning method, the fluidity of the airgel pow...

Embodiment 1

[0075] Using a two-component melt-blown nonwovens production line, PP (polypropylene, Sinopec T03-H) is used as the A component, and the cortex is melt-extruded at 190°C; at the same time, the silica airgel powder G200 ( Suzhou Tongxuan New Material Co., Ltd.) as component B, the core layer; using concentric spinneret holes, the airgel powder is extruded synchronously with PP in the form of a tube at 100 ° C, and the extrusion speed of PP is 0.1 g / hole / min, the extrusion speed of airgel powder is 0.02g / hole / min. The melted filaments are cooled by air flow to form PP airgel composite fibers.

[0076] The structure of the PP airgel composite fiber obtained in this example is concentric, the composite fiber diameter is 40 μm, the fiber wall thickness is 10 μm, the mass proportion of airgel particles in the composite fiber is about 15wt%, and the thermal conductivity of the composite fiber The coefficient is 0.02w / m·k, and the tensile strength of the composite fiber is enhanced b...

Embodiment 2

[0078] A two-component melt-blown nonwoven fabric production line is adopted, and PET (poly(ethylene glycol terephthalate), DuPont FR945 in the United States) is used as the A component, and the cortex is melt-extruded at 270°C; Dialuminum airgel powder is used as component B, the core layer; the airgel powder is extruded synchronously with PET in the form of a tube at 50°C by using a three-lobed spinneret hole, and the extrusion speed of PET is 0.1g / hole / min, the extrusion speed of the airgel powder is 0.01g / hole / min. The melted filaments are cooled by air flow to form PET airgel composite fibers.

[0079] The PET airgel composite fiber obtained in this example has a three-lobe structure, the diameter of the composite fiber is 30 μm, the fiber wall thickness is 8 μm, the mass ratio of the airgel particles in the composite fiber is about 10 wt%, and the thermal conductivity of the composite fiber The coefficient is 0.03w / m·k.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com