Smoke gas extraction system applied to ammonia escape detection and smoke gas extraction method

An extraction system and ammonia escape technology, applied in the fields of flue gas extraction, ammonia escape detection, and flue gas extraction systems, can solve the problems of easy blockage and can not represent the overall level of flue gas in the flue very well, so as to prolong life and save money. Cleaning and maintenance costs, reducing the effect of ammonium salt crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

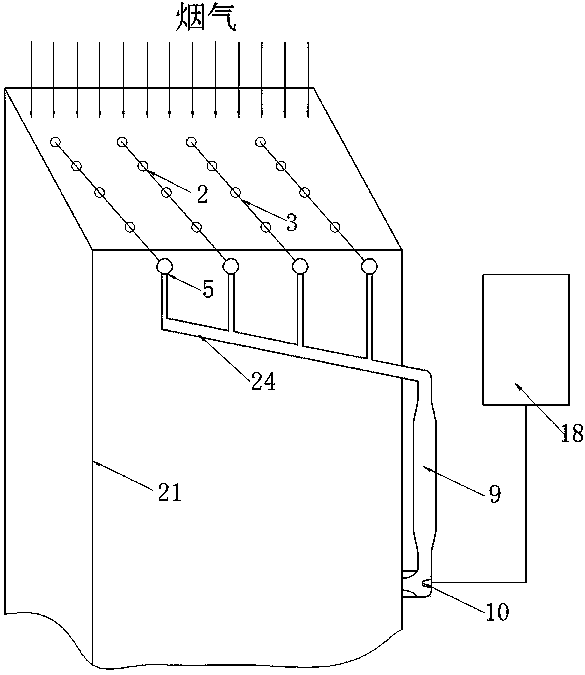

[0038] This embodiment provides a flue gas extraction system applied to the detection of ammonia escape, including a flue gas sampling device and an extraction power device, and also includes an anti-blocking device. The extraction heads 2 distributed in an area matrix, a plurality of extraction heads 2 are connected to the mixed gas main tank 9 through the sampling pipeline 3, and the mixed gas main tank 9 and the anti-blocking device are connected to the sampling pipeline 3 in parallel, and are all provided with valves, so The extraction power unit is connected to the mixed gas main tank 9. The mixed gas master tank 9 is connected with an ammonia escape detection device (to detect the amount of ammonia escape).

[0039] Principle of the present invention:

[0040] Since there is almost no straight pipe section in the rectangular duct of the flue 21, there are disturbance factors such as supports in the flue 21, which causes the flue gas flow field here to be chaotic. Moreo...

Embodiment 2

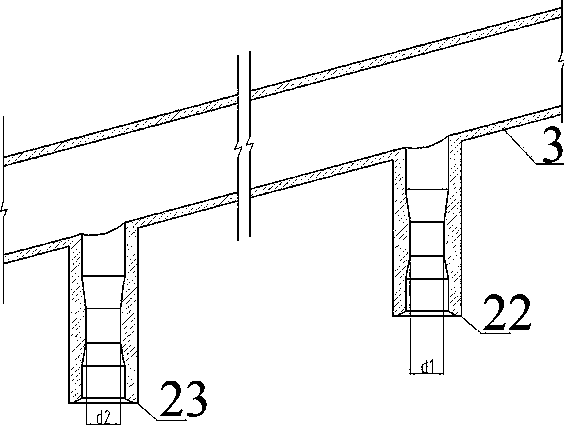

[0043] On the basis of Embodiment 1, this embodiment provides a smoke extraction system applied to the detection of ammonia escape. The hole diameter of the head 2 is related to the function of the smoke flow velocity at the location, and the location where the extraction head 2 has a large smoke flow velocity corresponds to a large hole diameter of the extraction head 2 .

[0044] To ensure that the extracted sample gas composition can represent the average composition of the flue gas in the flue 21 to the greatest extent, first arrange a plurality of extraction heads 2 in the flue 21 (for example, a 4m x 6m The flue 21 is arranged with 16 extraction heads 2; the 7m×9m flue 21 of the 600MW unit is arranged with 24 extraction heads 2); secondly, the amount of sample gas extracted by each extraction head 2 and the extraction head The flue gas flow rate in the pipe at the location of 2 must be proportional, and multiple extraction heads 2 cover the flue section.

[0045] Flue g...

Embodiment 3

[0059] On the basis of Embodiment 1, this embodiment provides a flue gas extraction system applied to ammonia escape detection, the anti-blocking device includes a back-purging device and a first jet pump 7, and the back-purging device includes Back purge pipeline and hot compressed air tank 18, described hot compressed air tank 18 communicates with sampling pipeline 3 through back purge pipeline, first solenoid valve 4 is arranged on the described back purge pipeline, and described sampling pipeline 3 and the communication pipeline of the mixed gas main tank 9 is provided with a second electromagnetic valve 5, the outlet of the first jet pump 7 communicates with the flue 21, the suction port of the first jet pump 7 communicates with the sampling pipeline 3, communicates A third solenoid valve 6 is arranged on the pipelines of the two, and the high-pressure port is connected to a hot compressed air tank 18 through a pipeline, and a fourth solenoid valve 8 is arranged on the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com