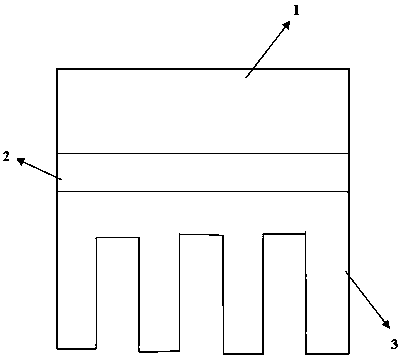

Preparation method of aluminium nitride bottom plate and copper heat sink complex

A technology of aluminum nitride and composites, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problems of unfavorable heat dissipation and cooling, and the effective specific surface area of heat dissipation is small, so as to increase the specific surface area and effectively Good for heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The copper heat sink was cleaned sequentially with acetone, ethanol and deionized water to remove the organic layer on the surface. The powder of the polymer baffle with nanopores is dispersed in the aqueous solution to form a suspension, and the powder is uniformly dispersed by ultrasonic vibration. Draw up the suspension with a rubber dropper, and drop it into the sawtooth of the copper heat sink and on the surface of the copper heat sink several times. Put the copper heat sink into the vacuum oven, under the vacuum of 120 o C baked for 2 hours, after removing moisture, the polymer baffle was adsorbed on the copper surface. Use solder to connect the copper heat sink and the wire to make the electrode, and immerse the copper heat into the electrolyte, which is 0.1 M CuSO 4 + 1 M H 2 SO 4 mixture. Connect the copper heat sink electrode with the CHI660D electrochemical workstation, use Ag / AgCl as the reference electrode, and platinum sheet as the counter electrode...

Embodiment 2

[0023] The copper heat sink was cleaned sequentially with acetone, ethanol and deionized water to remove the organic layer on the surface. The powder of the polymer baffle with nanopores is dispersed in the aqueous solution to form a suspension, and the powder is uniformly dispersed by ultrasonic vibration. Draw up the suspension with a rubber dropper, and drop it into the sawtooth of the copper heat sink and on the surface of the copper heat sink several times. Put the copper heat sink into the vacuum oven, under the vacuum of 120 o C baked for 2 hours, after removing moisture, the polymer baffle was adsorbed on the copper surface. Use solder to connect the copper heat sink and the wire to make the electrode, and immerse the copper heat into the electrolyte, the electrolysis is 0.2 M CuSO 4 + 1.5M H 2 SO 4 mixture. Connect the copper heat sink electrode with the CHI660D electrochemical workstation, use Ag / AgCl as the reference electrode, and platinum sheet as the count...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com