Door and window sealing strip composition and preparation method thereof

A technology of sealing strip and composition, applied in the field of chlorinated polyethylene sealing strip composition and preparation thereof, can solve the problems of performance decline, high market price, poor cold resistance, etc., and achieve high tensile strength and low temperature brittle resistance. Improve performance, improve production efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

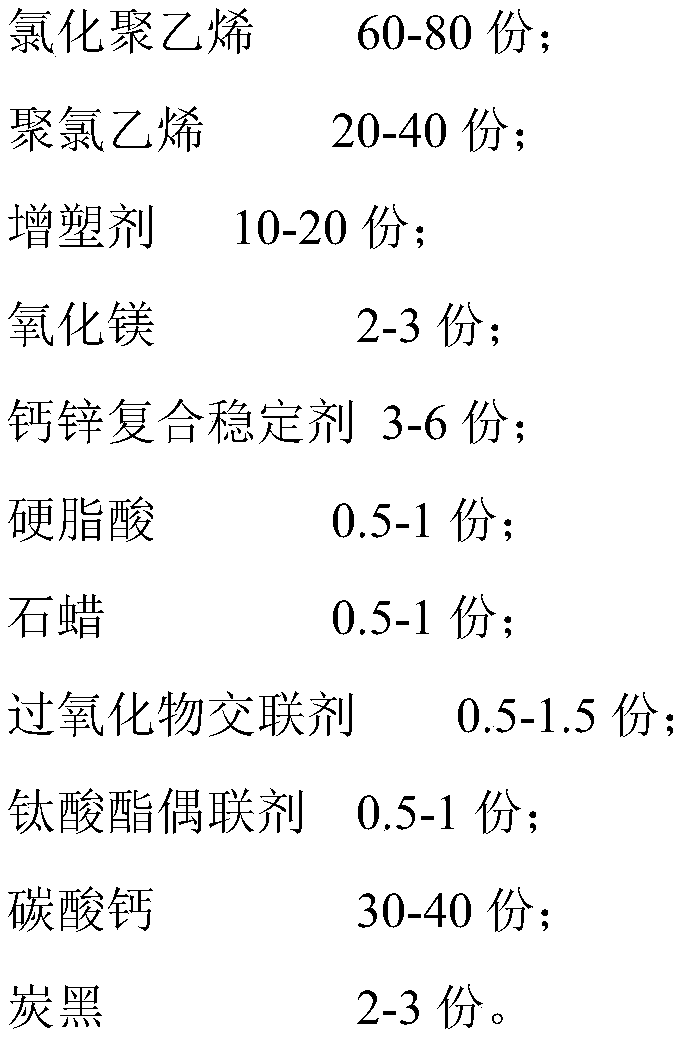

Method used

Image

Examples

preparation example Construction

[0054] The synthetic method of carbon dioxide base polymer, comprises the steps:

[0055] 1) dry monomer: epoxy compound with CaH at room temperature 2 Mixed, stirred for two days, evaporated under reduced pressure, degassed three times to remove oxygen, and then stored at low temperature under anhydrous and anaerobic conditions for later use; 2 After passing through the dehydration and deoxygenation silica gel column, it is passed into step 2) polymerization reaction system;

[0056] 2) Polymerization reaction: Pre-install a stirrer in the autoclave, put it into the glove box, add 38.5mg of rare earth dialkyl compound as a catalyst, then measure 2mL of cyclohexene oxide and add it to the autoclave, after the autoclave is assembled Take out the glove box, put CO 2 To the pressure of 4.9MPa, adjust the heater to the reaction temperature of 70°C, start timing, and react for 15 to 48 hours; after the reaction is completed, add chloroform to dilute the reaction solution, and the...

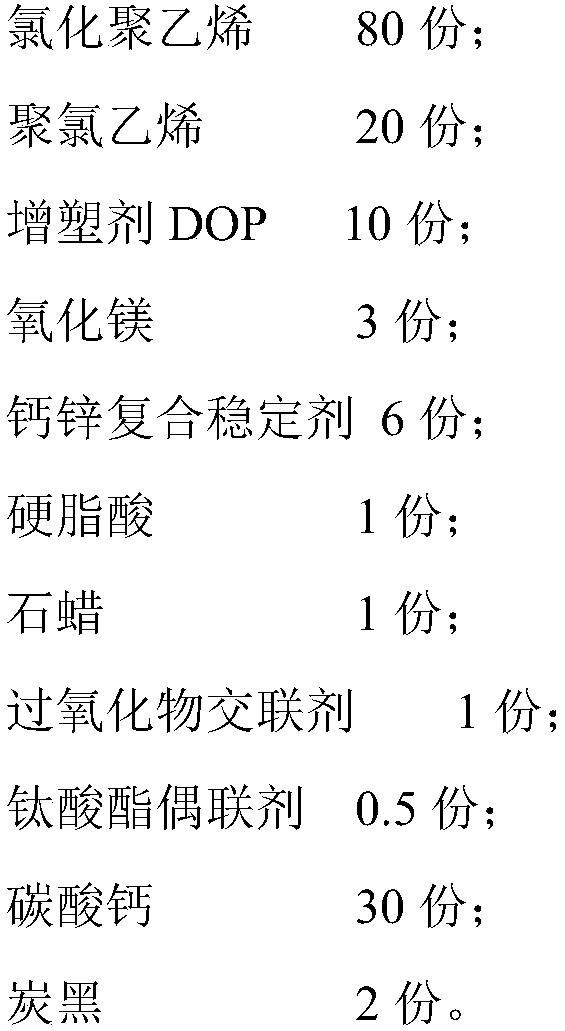

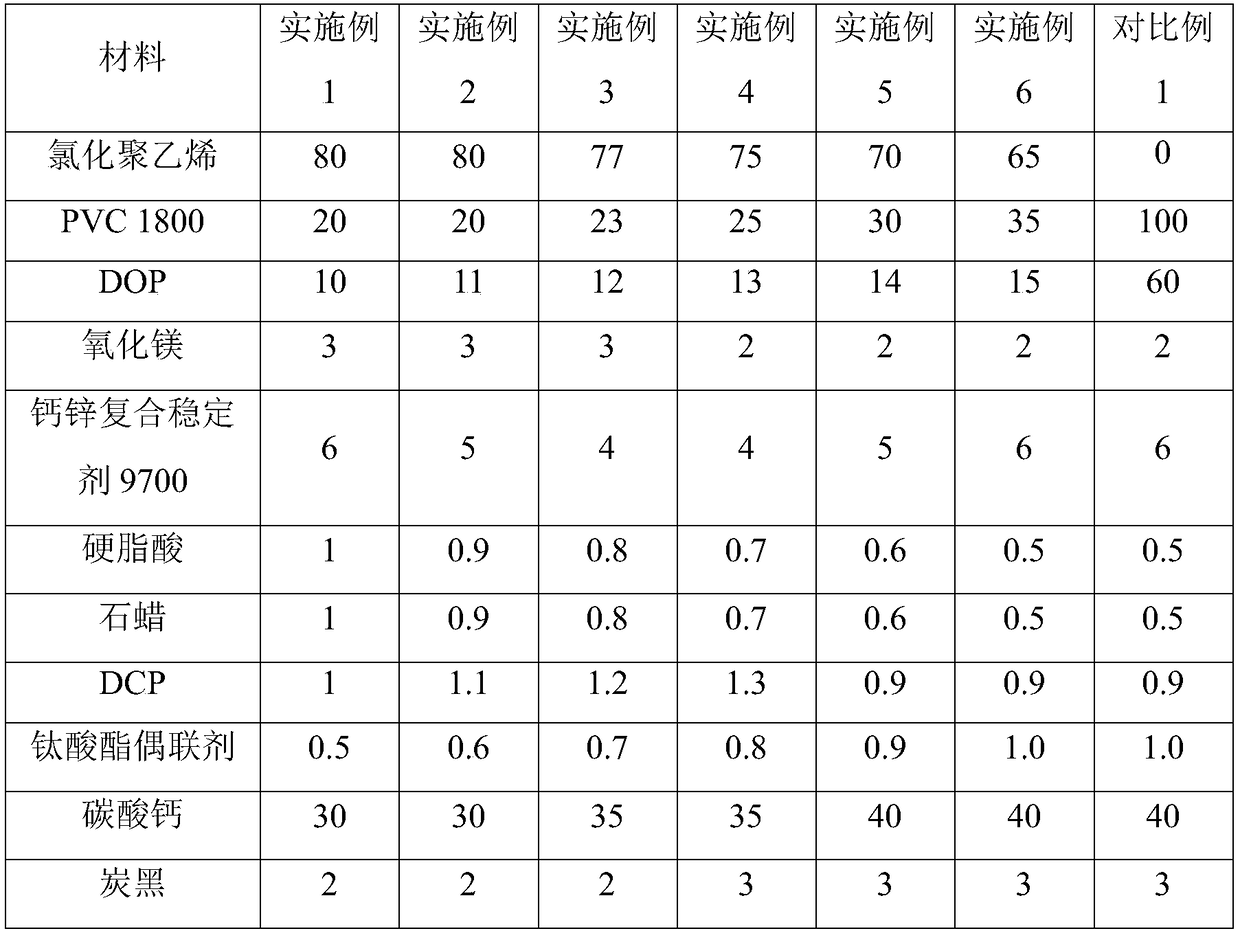

Embodiment 1~12

[0058] The preparation method of embodiment 1~12 adopts following steps:

[0059] 1) Add chlorinated polyethylene, polyvinyl chloride, calcium-zinc composite stabilizer, magnesium oxide, stearic acid, paraffin and DCP into the high-speed mixer, start high-speed mixing and slowly add DOP, and finally add carbon black and titanium dioxide Calcium carbonate pretreated with ester coupling agent, stirred at 90 degrees for 5 minutes.

[0060] 2) Add the above powder into the twin-screw extruder for shear extrusion granulation, the twin-screw structure is combined into strong shear, and the granulation temperature

[0061] 160-170 degrees, the obtained thermoplastic elastic pellets can be used for the production of plastic door and window sealing strips.

[0062] The preparation method of calcium carbonate pretreated by titanate coupling agent described in step 1): add calcium carbonate in the mixer, start stirring, heat up to 70°C-80°C, and then uniformly add titanate by spraying m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com