Electromagnetic resonance type inertial damper

A resonant and damper technology, applied in the field of electromagnetic resonance inertial dampers, can solve the problems of limited range of changing magnetic field strength, limited adaptability of dampers, low sensitivity of vibration switches, etc., and achieves excellent vibration reduction effect, life stiffness With the effect of controllable damping and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

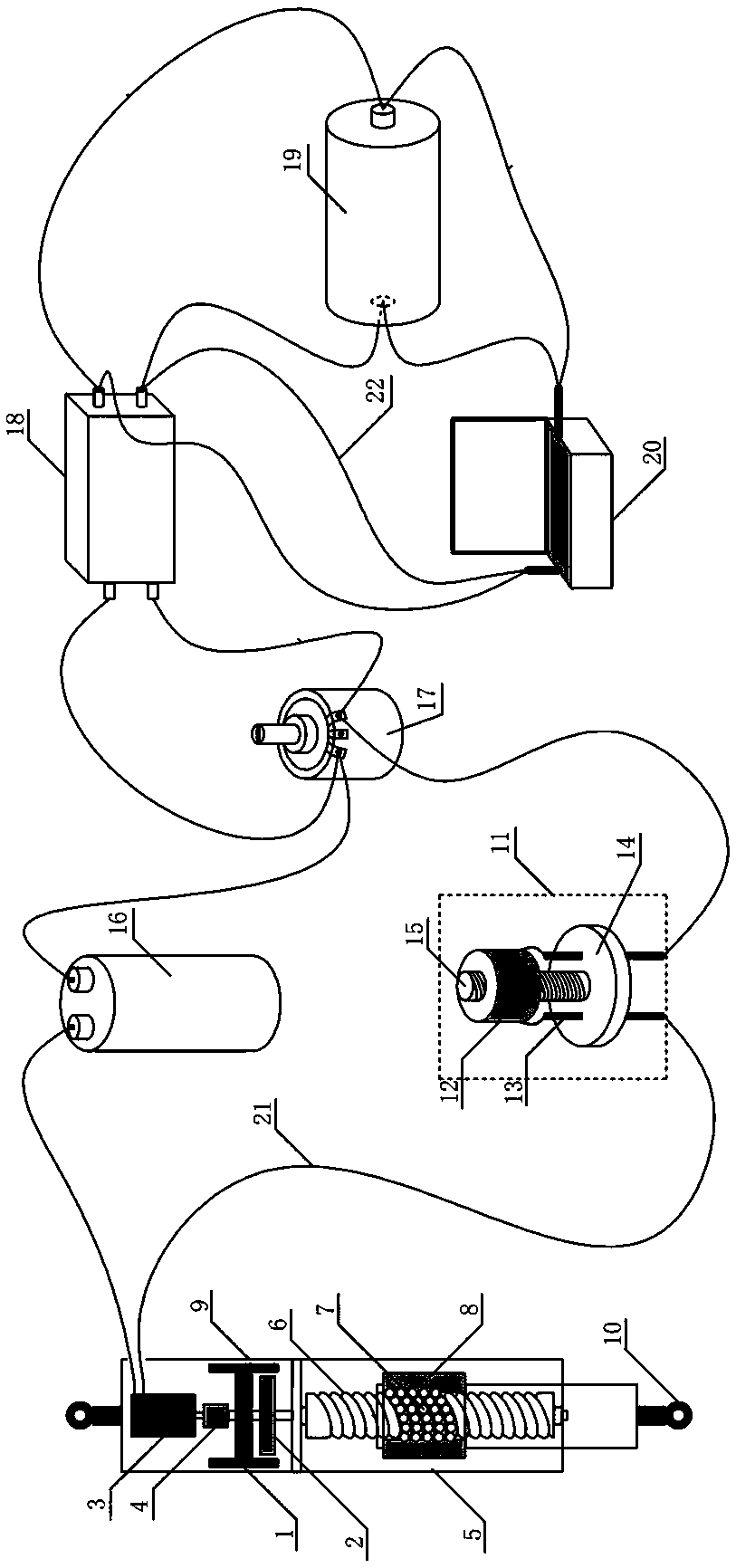

[0019] Such as figure 1 As shown, the present invention comprises a ball screw mechanism 5, a gearbox 2, a rotating flywheel 1 and a generator 3, the generator 3 and the gearbox 2 are installed in the tailpiece 9, the input shaft of the generator 3 and the output shaft of the gearbox 2 Connection; the input shaft of the gearbox 2 is connected with the upper end of the rotating flywheel 1, and the lower end of the rotating flywheel 1 is connected with the leading screw of the ball screw mechanism 5; the nut of the ball screw mechanism 5 is connected with the upper end of the connector 10. The output terminal of generator 3 is connected with the resistance-inductance-capacitance RLC series resonant circuit, and the resistance-inductance-capacitance RLC series resonant circuit is connected with the input terminal of the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com