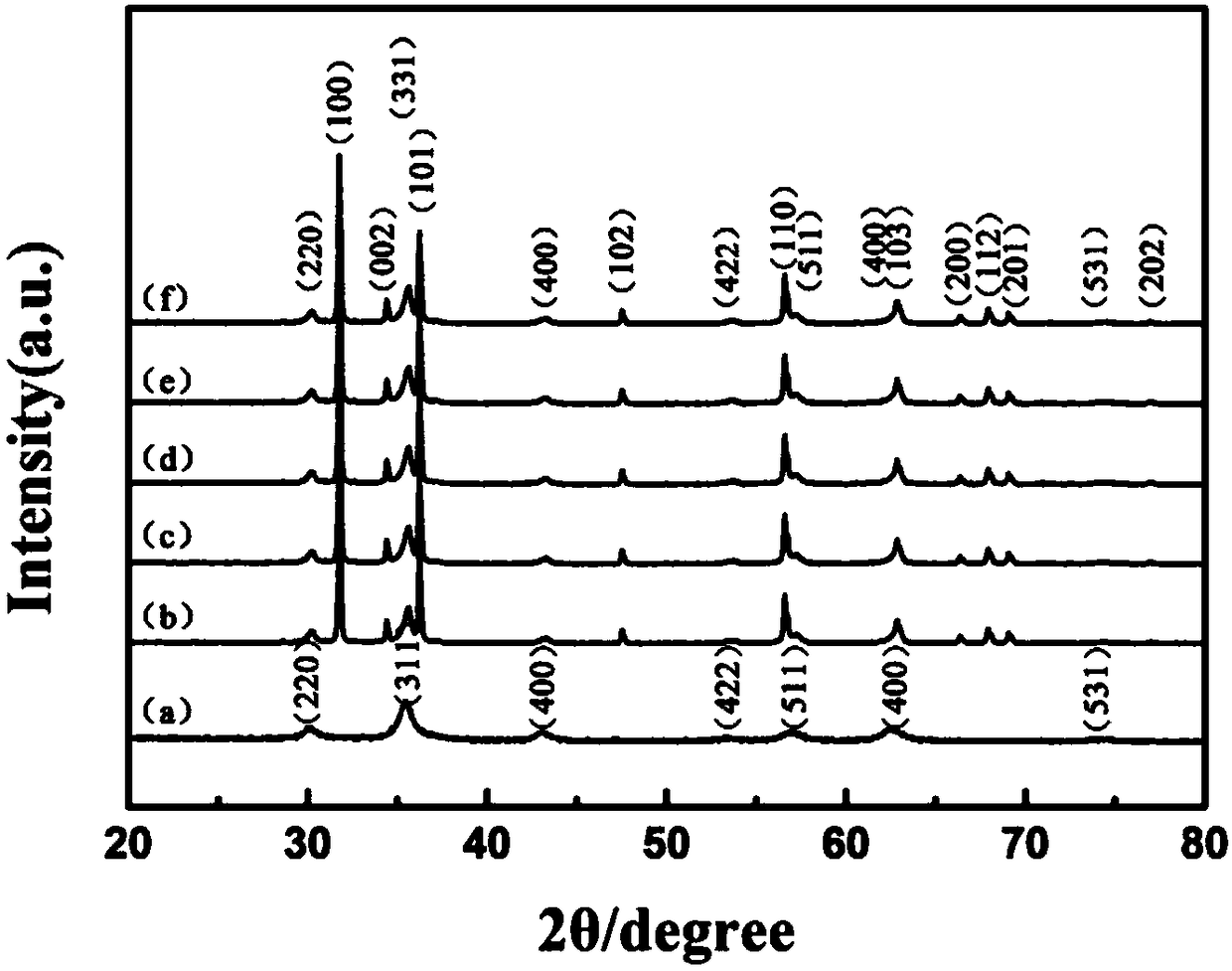

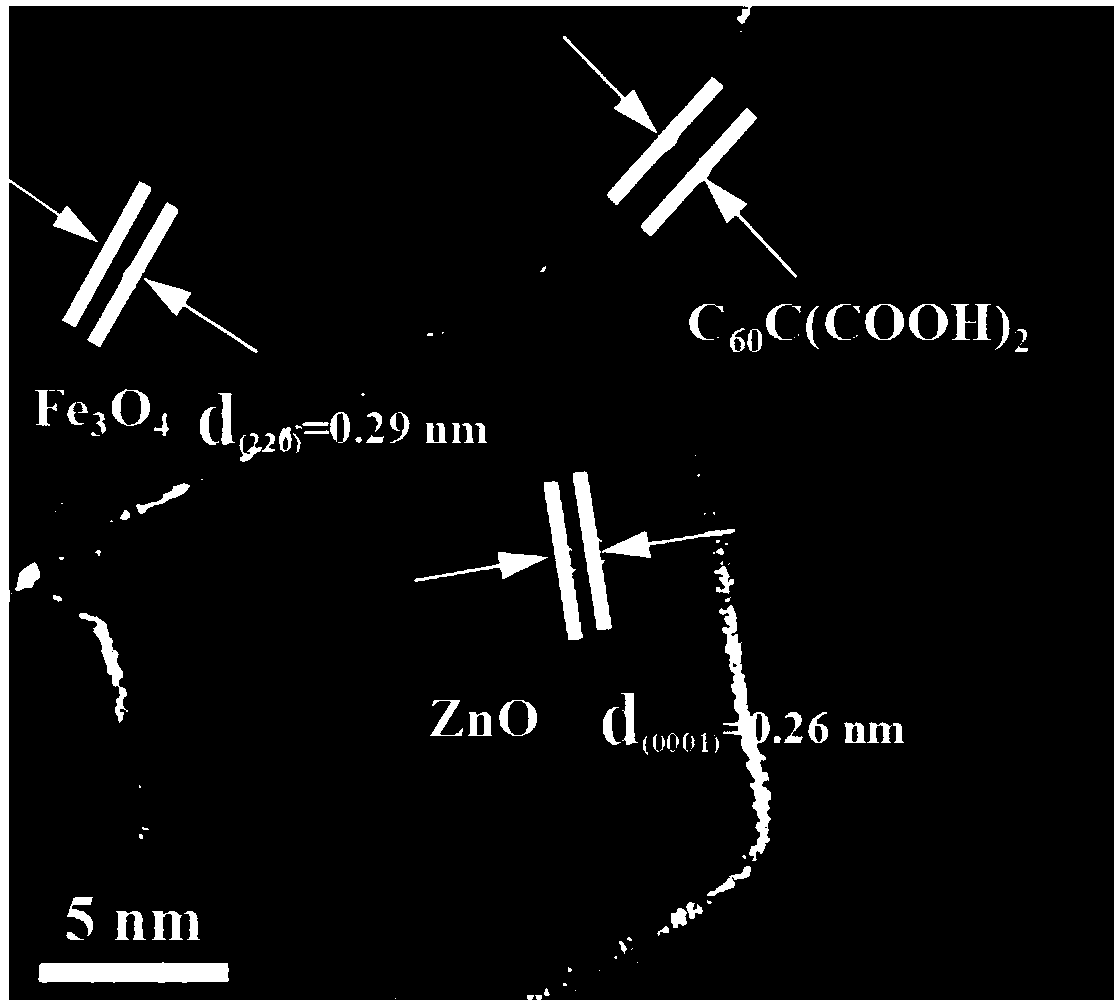

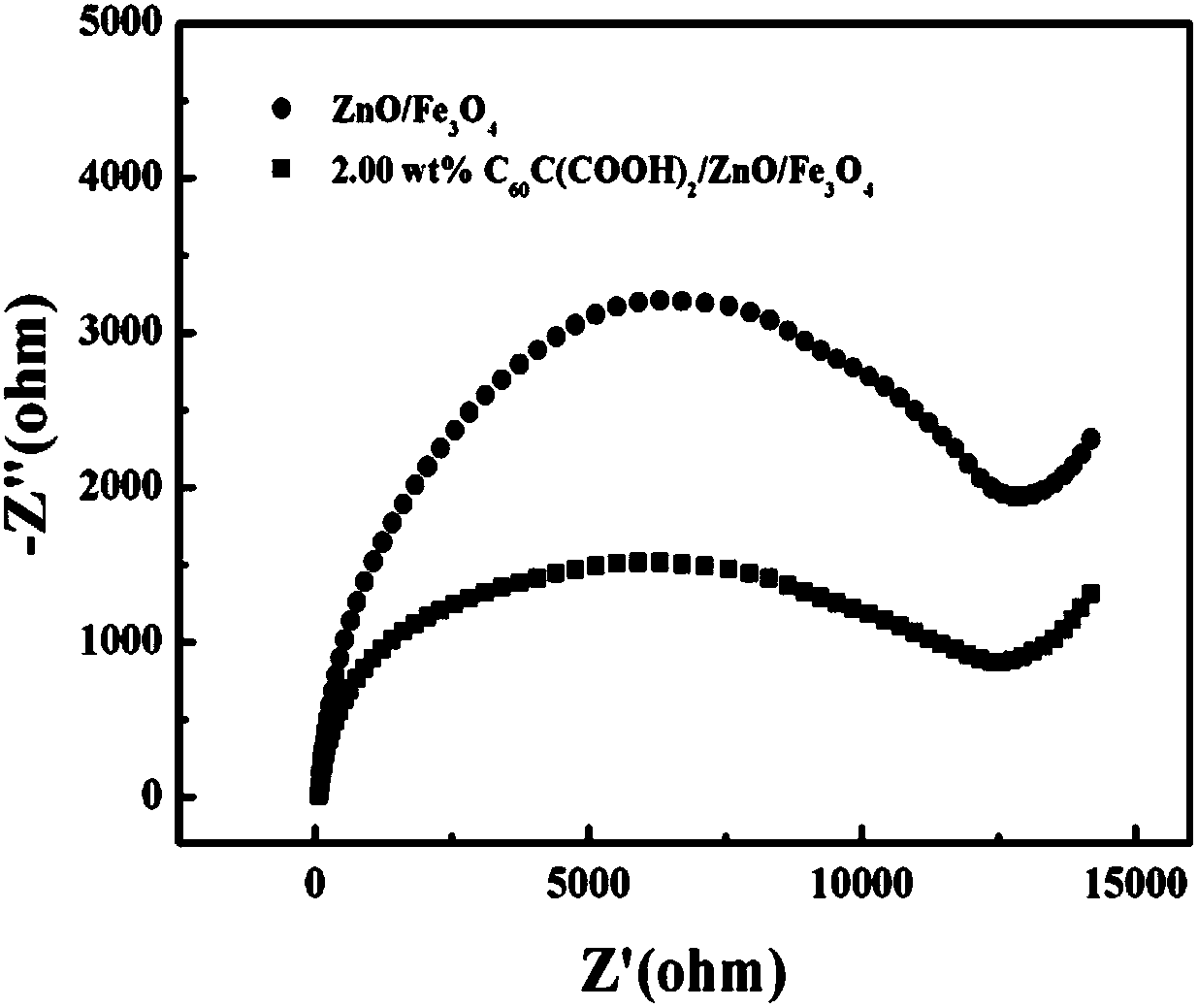

Preparation and application of C60C(COOH)2/ZnO/Fe3O4 ternary composites

A technology of composite materials and nanomaterials, which is applied in the field of simple preparation of C60C2/ZnO/Fe3O4 ternary composite materials, can solve the problems of narrow photoresponse range of ZnO, high recombination rate of photogenerated electrons and holes, and limited photocatalytic activity. Improve adsorption and photocatalytic activity, use less raw materials, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.2 g of fullerene powder, dissolve it in 200 mL of toluene, stir for 1 h to fully dissolve the fullerene, then add 47 μL of diethyl bromomalonate and 120 μL of catalyst 1,8-diazabicyclo Undec-7-ene, stirred and reacted for 1h, after the reaction was completed, the solution was evaporated to dryness, and then a mixed solvent of petroleum ether and toluene (volume ratio = 2.5:1) was used as a developing solvent for column separation to obtain the product Fuller Diethyl Allenate. Weigh 100mg of synthesized diethyl fullerene malonate, dissolve it in 50mL of toluene, add 40mg of NaH, stir and react at 60°C for 5h, and wash with toluene, sulfuric acid and secondary water successively after the reaction is completed, that is The target product C can be obtained 60 C(COOH) 2 .

[0026] Then weigh 1.622g FeCl 3 ·6H 2 O (5mmol), 0.597g FeCl 2 4H 2 O (3mmol), dissolved in 200mL of distilled water, ultrasonically dispersed, mechanically stirred at 45°C for 1.5h, then ...

Embodiment 2

[0029] ZnO / Fe 3 o 4 The preparation mode of nanometer material is with embodiment 1.50mg / L C 60 C(COOH) 2 The preparation of the toluene solution is also the same as in Example 1.

[0030] Weigh 50mg of ZnO / Fe 3 o 4 Compound was added to 15mL C 60 C(COOH) 2 in toluene solution, stirred at room temperature for 14h, and after drying, C 60 C(COOH) 2 Mass fraction of 1.50% C 60 C(COOH) 2 / ZnO / Fe 3 o 4 Ternary composite materials.

Embodiment 3

[0032] ZnO / Fe 3 o 4 The preparation mode of nanometer material is with embodiment 1.50mg / L C 60 C(COOH) 2 The preparation of the toluene solution is also the same as in Example 1.

[0033] Weigh 50mg of ZnO / Fe 3 o 4 Compound was added to 20mL C 60 C(COOH) 2 in toluene solution, stirred at room temperature for 12h, and after drying, C 60 C(COOH) 2 C with a mass fraction of 2.00% 60 C(COOH) 2 / ZnO / Fe 3 o 4 Ternary composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com