Synthesis method for Ti3SiC2 powder

A synthesis method and powder technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of difficult control of synthesis temperature and reaction degree, difficulty of industrialization, harsh process conditions, etc., and shorten the synthesis time , reduce the synthesis temperature and shorten the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

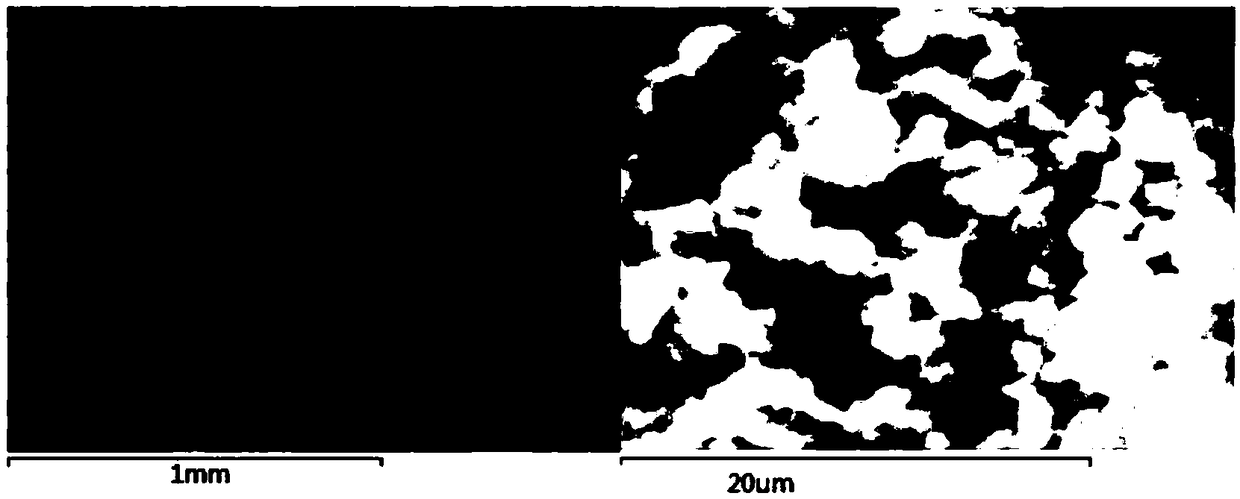

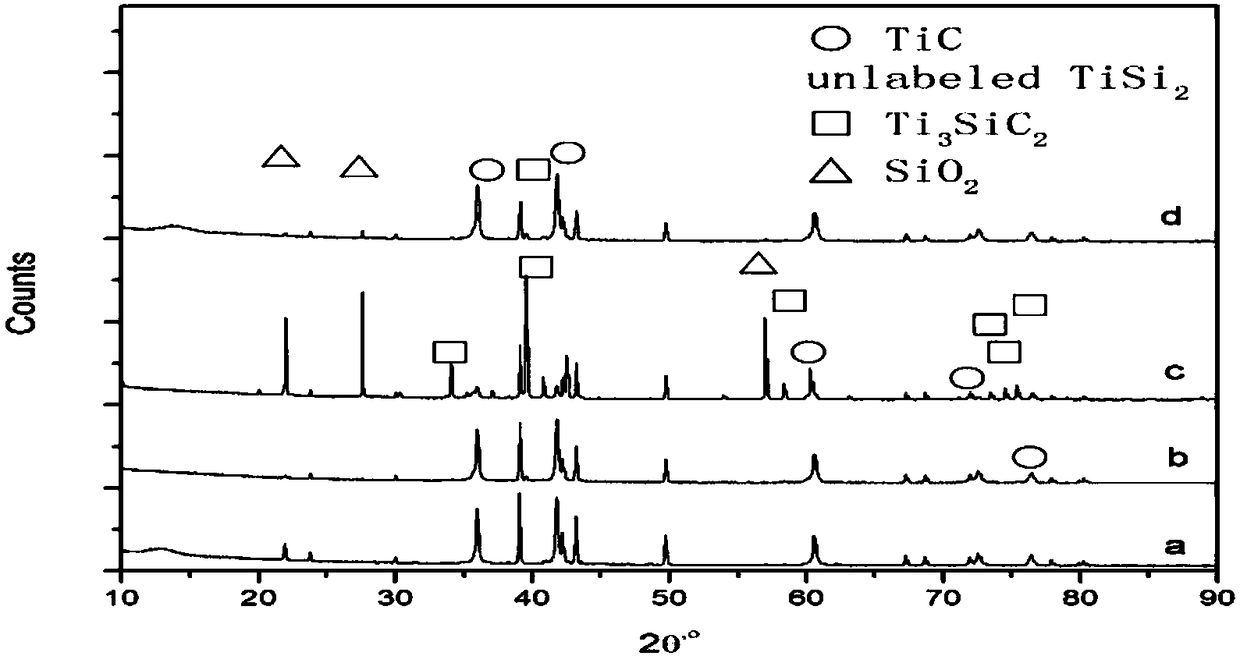

Embodiment 1

[0034] A kind of Ti 3 SiC 2 The synthetic method of powder (titanium silicon carbon powder), specifically comprises the following steps:

[0035]The first step: mixing materials, specifically: raw materials and mixed molten salt are mixed evenly according to the proportion (using a glass rod to stir evenly, and the stirring speed is 120r / min), to obtain a mixed powder, wherein: the raw material is Ti powder (titanium powder), Si powder (silicon powder) and C powder (carbon powder), wherein: the molar ratio of Ti powder, Si powder, and C powder is 3:3:2; the mixed molten salt is KCl powder (potassium chloride powder) and NaF powder (sodium fluoride powder), wherein the mass ratio of KCl powder and the NaF powder is 1:1. Wherein the mass ratio of the raw material (Ti powder+Si powder+C powder) to the mixed molten salt (KCl powder+NaF powder) is 1:1, the total weight of the mixed powder is equal to the mass of the raw material and The sum of the masses of the mixed molten salt...

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that the molar ratio of Ti powder: Si powder: C powder is 3:2:2, specifically: weigh 144g of Ti powder, 56g of Si powder, 24g of C powder, 112g of NaF powder and 112g of KCl Powder. The produced Ti 3 SiC 2 The powder is a nano single crystal with a particle diameter of 500-600nm, a purity of over 90%, uniform particle size and good dispersibility.

Embodiment 3

[0043] The difference between Example 3 and Example 1 is that the molar ratio of Ti powder: Si powder: C powder is 3:3.5:2, specifically: weigh 144g Ti powder, 98g Si powder, 24g C powder, 133gNaF powder and 133g KCl powder. The produced Ti 3 SiC 2 The powder is a nano single crystal with a particle diameter of 500-600nm, a purity of over 90%, uniform particle size and good dispersibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com