A kind of perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problem of no effective method for perovskite thin films, and achieve the effects of improving efficiency and stability, good repeatability, and good device stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

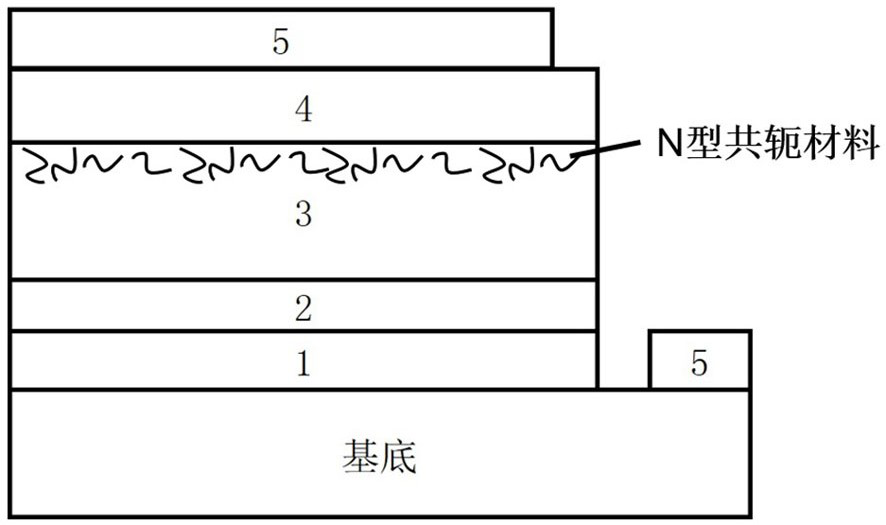

[0031] See attached figure 1 , which is a schematic structural view of the perovskite solar cell prepared in this example. In the present invention, at room temperature, on the cathode of the substrate 1, an oven is used to pass TiCl at 70°C 4 Preparation of TiO by Hydrothermal Method 2 The thin film was annealed at 200°C for 30 minutes to prepare the electron transport layer 2; the perovskite precursor solution was spin-coated on the prepared electron transport layer 2; Perovskite crystallization is induced, followed by annealing at 100° C. for 20 minutes to obtain a perovskite light-absorbing layer 3 of about 300-450 nanometers. A hole transport layer 4 with a thickness of 180 nm is prepared on the perovskite light absorbing layer 3 . Transfer the sample to a thermal evaporation system to evaporate a metal anode 5 to prepare a perovskite solar cell. Specific steps are as follows:

[0032] Step 1, cleaning the cathode 1 composed of the glass substrate and the transparent...

Embodiment 2

[0043] Step 1, cleaning the cathode composed of the glass substrate and the transparent electrode with acetone, detergent, isopropanol and acetone respectively. After 20 minutes of ultraviolet ozone on the substrate, on the cathode substrate, pass TiCl at 70°C in an oven 4 Preparation of TiO by Hydrothermal Method 2 The thin film was annealed at 200°C for 30 minutes to prepare the electron transport layer.

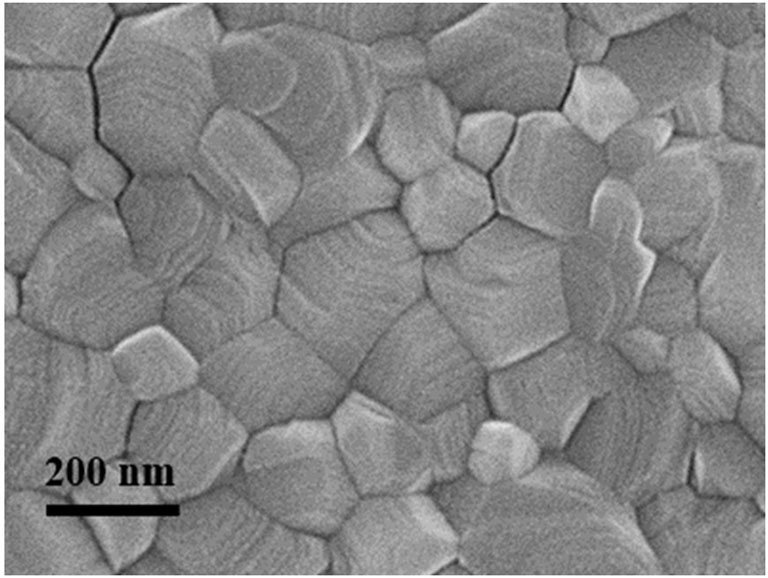

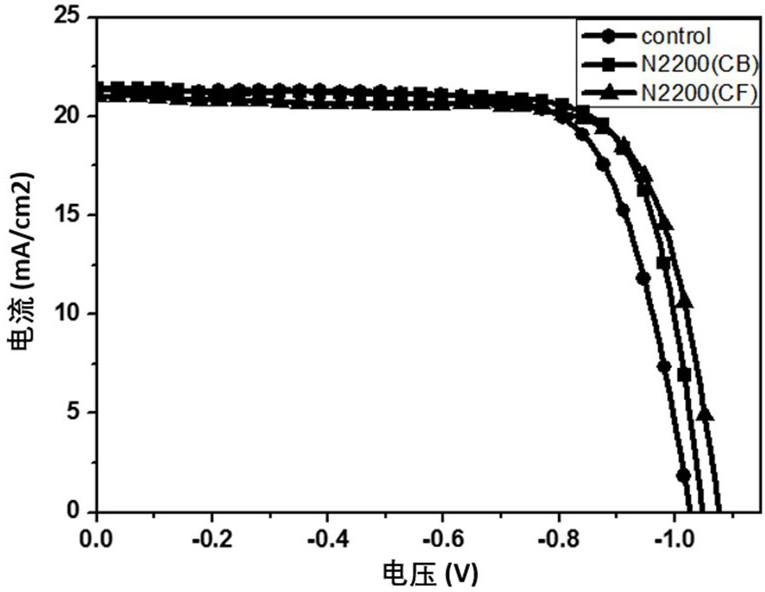

[0044] Step 2, apply ultraviolet ozone to the substrate for 10 minutes, and prepare a perovskite light-absorbing layer on the electron transport layer by spin coating; specifically, mix lead iodide and methylamino iodide in a molar ratio of 1:1, and use DMSO (dimethyl sulfoxide) and GBL (γ-butyrolactone) were mixed and dissolved to obtain a perovskite precursor solution of 1.2 mol / L to 2 mol / L, and the spin coating precursor solution was rotated for 20s to 30s, then drip Add a chlorobenzene solution with a concentration of 0.4mg / mL F-N2200 to induce crystallization, or d...

Embodiment 3

[0051] Step 1, cleaning the cathode composed of the glass substrate and the transparent electrode with acetone, detergent, isopropanol and acetone respectively. After 20 minutes of ultraviolet ozone on the substrate, on the cathode substrate, pass TiCl at 70°C in an oven 4 Preparation of TiO by Hydrothermal Method 2 The thin film was annealed at 200°C for 30 minutes to prepare the electron transport layer.

[0052] Step 2, apply ultraviolet ozone to the substrate for 10 minutes, and prepare a perovskite light-absorbing layer on the electron transport layer by spin coating; specifically, mix lead iodide and methylamino iodide in a molar ratio of 1:1, and use DMSO (dimethyl sulfoxide) and GBL (γ-butyrolactone) were mixed and dissolved to obtain a perovskite precursor solution of 1.2 mol / L to 2 mol / L. A chlorobenzene solution with a concentration of 0.4 mg / mL ITIC induces crystallization. After the solvent is further volatilized, it is annealed at 100 °C for 10 minutes to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com