Graphene-based porous carbon flake material, and preparation method and application thereof

A technology of graphene and sheet materials, applied in electrical components, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of inability to meet the long-term cycle and commercialization requirements of lithium-sulfur batteries, poor battery cycle performance, and low sulfur utilization rate. To achieve the effect of suppressing the shuttle effect, improving the utilization rate and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of graphene-based porous carbon sheet materials

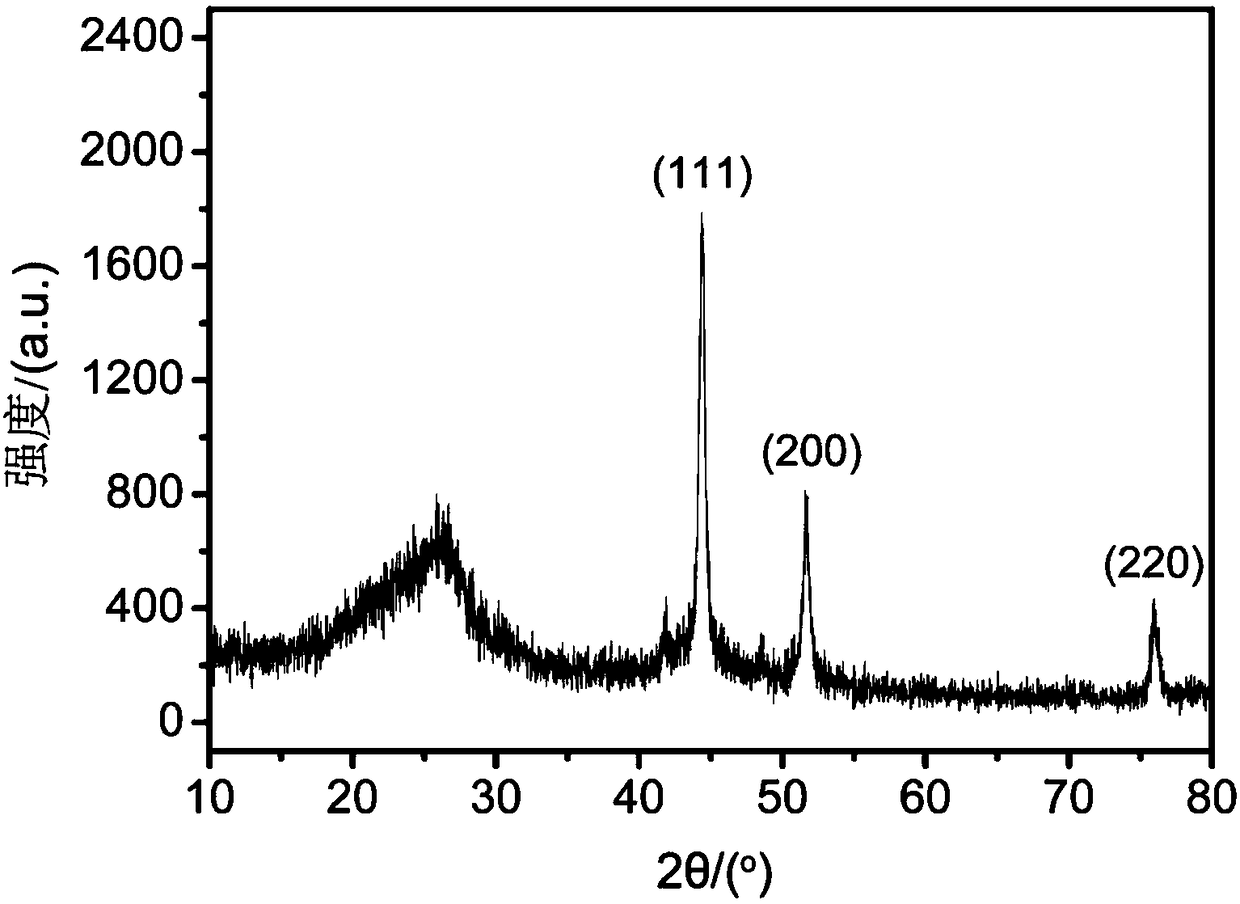

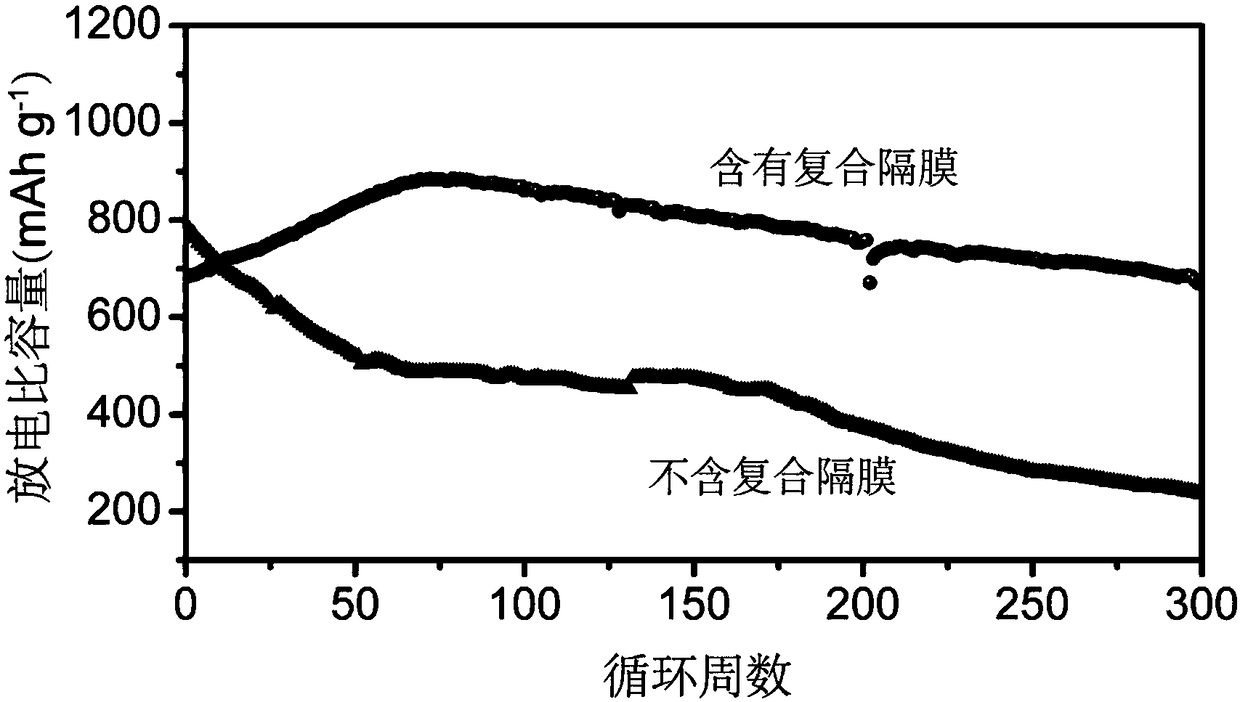

[0036] At room temperature, 5 mL of graphene oxide solution (10 mg / mL) was added dropwise to 200 mL of methanol solution, ultrasonically dispersed for 5 h, then 300 mg of polyvinylpyrrolidone was added, and stirred for 1 h to obtain mixed solution 1; 3.09 g of Zn(NO 3 ) 2 ·6H 2 O and 0.61g Co(NO 3 ) 2 ·6H 2 O was dissolved in the above mixed solution 1, and stirred at room temperature for 3 h to obtain mixed solution 2; then 60 mL of 2-methylimidazole (4.25 g) in methanol was quickly added to the above mixed solution 2, and stirred at room temperature for 30 min until precipitation occurred. Centrifuge after standing for 6 hours, wash the precipitate with anhydrous methanol 3 times to remove impurities, and freeze-dry the obtained precipitate in a freeze dryer for 24 hours to obtain an intermediate product; calcinate the intermediate product at 950°C for 3 hours in a tube furnace with a nitrogen atmos...

Embodiment 2

[0049] (1) Preparation of graphene-based porous carbon sheet materials

[0050] At room temperature, 5 mL of graphene oxide solution (10 mg / mL) was added dropwise to 200 mL of methanol solution, ultrasonically dispersed for 5 h, then 300 mg of polyvinylpyrrolidone was added, and stirred for 1 h to obtain mixed solution 1; 2.48 g of Zn(NO 3 ) 2 ·6H 2 O and 1.21g Co(NO 3 ) 2 ·6H 2 O was dissolved in the above mixed solution 1, and stirred at room temperature for 3 h to obtain mixed solution 2; then 60 mL of 2-methylimidazole (4.25 g) in methanol was quickly added to the above mixed solution 2, and stirred at room temperature for 30 min until precipitation occurred. After standing for 6 hours, centrifuge, wash the precipitate with anhydrous methanol 3 times to remove impurities, and place the obtained precipitate in a freeze dryer for 24 hours to obtain the intermediate product; the intermediate product is calcined at 950°C for 3 hours in a tube furnace with a nitrogen atmosp...

Embodiment 3

[0063] (1) Preparation of graphene-based porous carbon sheet materials

[0064] At room temperature, 5 mL of graphene oxide solution (10 mg / mL) was added dropwise to 200 mL of methanol solution, ultrasonically dispersed for 5 h, then 300 mg of polyvinylpyrrolidone was added, and stirred for 1 h to obtain mixed solution 1; 3.53 g of Zn(NO 3 ) 2 ·6H 2 O and 0.17g Co(NO 3 ) 2 ·6H 2 O was dissolved in the above mixed solution 1, and stirred at room temperature for 3 h to obtain mixed solution 2; then 60 mL of 2-methylimidazole (4.25 g) in methanol was quickly added to the above mixed solution 2, and stirred at room temperature for 30 min until precipitation occurred. After standing for 6 hours, centrifuge, wash the precipitate with anhydrous methanol 3 times to remove impurities, and place the obtained precipitate in a freeze dryer for 24 hours to obtain the intermediate product; the intermediate product is calcined at 950°C for 3 hours in a tube furnace with a nitrogen atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap