Cooling crystallization device of potassium nitrate

A cooling crystallization, potassium nitrate technology, applied in the general layout of the crystallization device, solution crystallization, crystallization separation and other directions, can solve the problems of high cost, low raw material utilization rate, inconvenient impurity potassium nitrate crystals, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

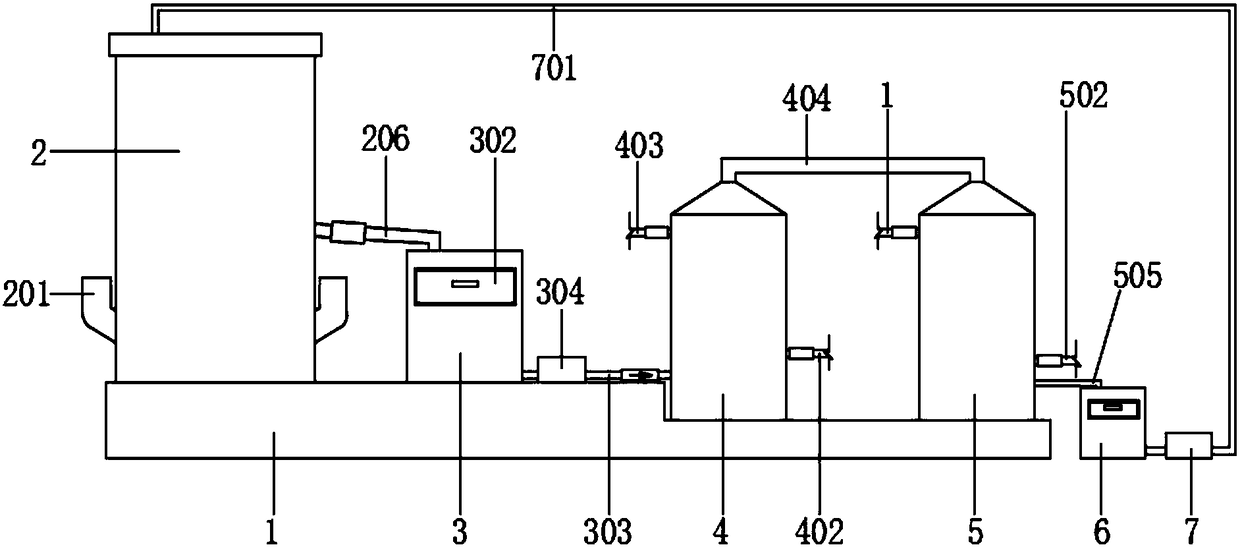

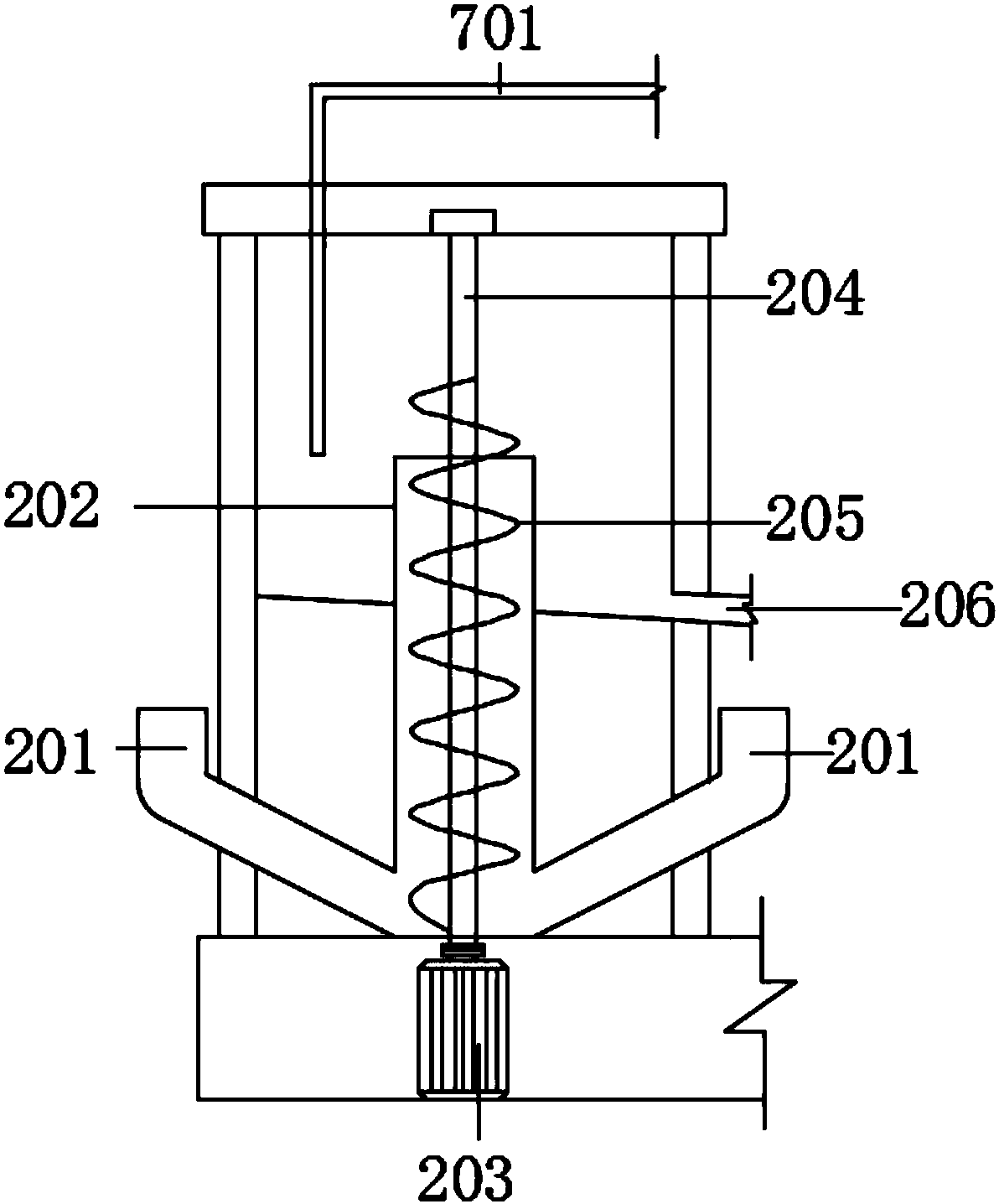

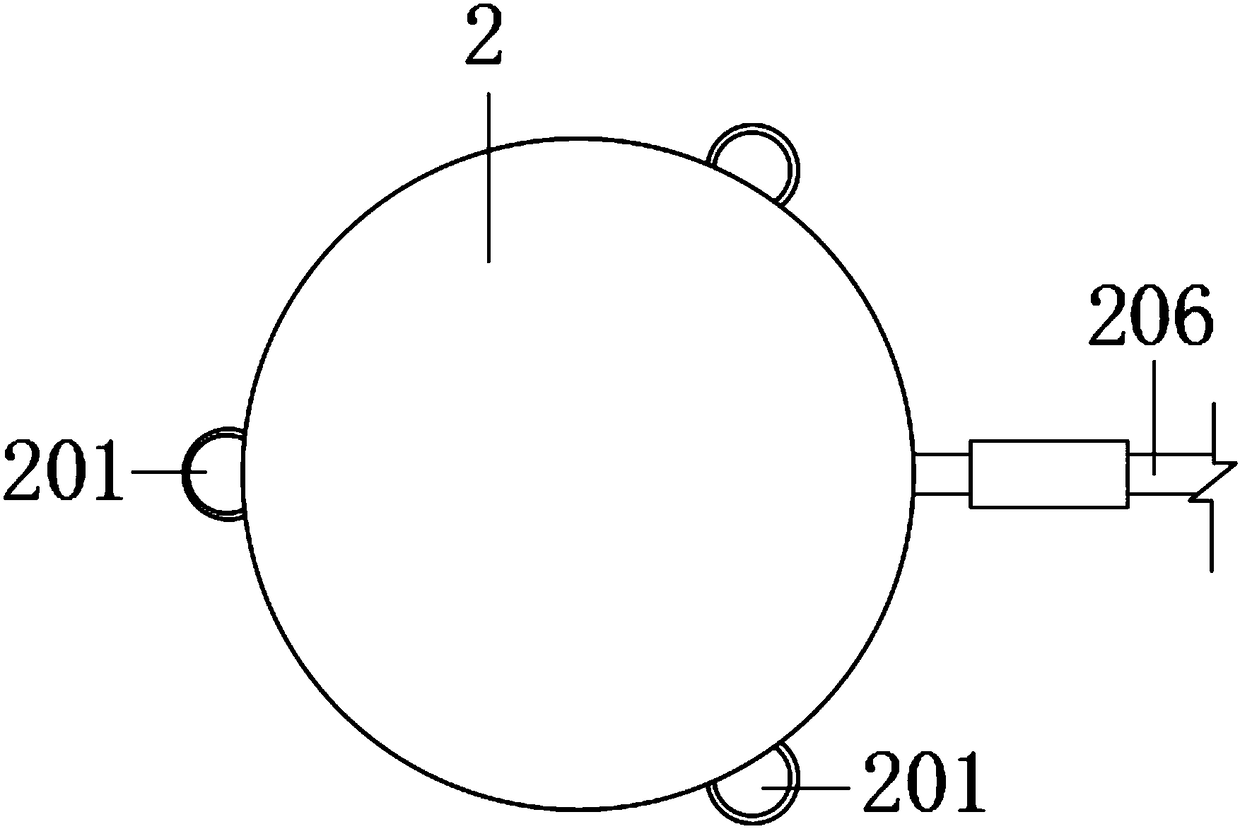

[0035] as attached figure 1 to attach Figure 7 Shown:

[0036]The present invention provides a cooling and crystallization device for potassium nitrate, which includes a bottom plate 1, a stirring device 2, a feeding pipe 201, an upper material cylinder 202, a conveying motor 203, a conveying shaft 204, a screw conveying blade 205, a discharge pipe 206, and a first-stage Square filter cartridge 3, pallet 301, filter drawer 302, delivery pipe 303, delivery pump 304, nozzle 305, evaporation cylinder 4, heating cavity 401, steam inlet pipe 402, steam outlet pipe 403, evaporation delivery pipe 404, Manhole 405, square condensation cylinder 5, cooling cavity 501, cooling water inlet pipe 502, cooling water outlet pipe 503, inclined baffle 504, mixing outlet pipe 505, secondary square filter cartridge 6, circulation pump 7 and return pipe 701 The stirring device 2 is fixedly installed on the top end of the base plate 1, and the three groups of feed pipes 201 all pass through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com