Catalyst based on carbonized polyurethane material, preparation method of catalyst and method for preparing cyclopentanone by using catalyst

A technology of polyurethane materials and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as catalyst deactivation and product yield decline, and achieve Effects of large specific surface area, water and thermal stability, excellent catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

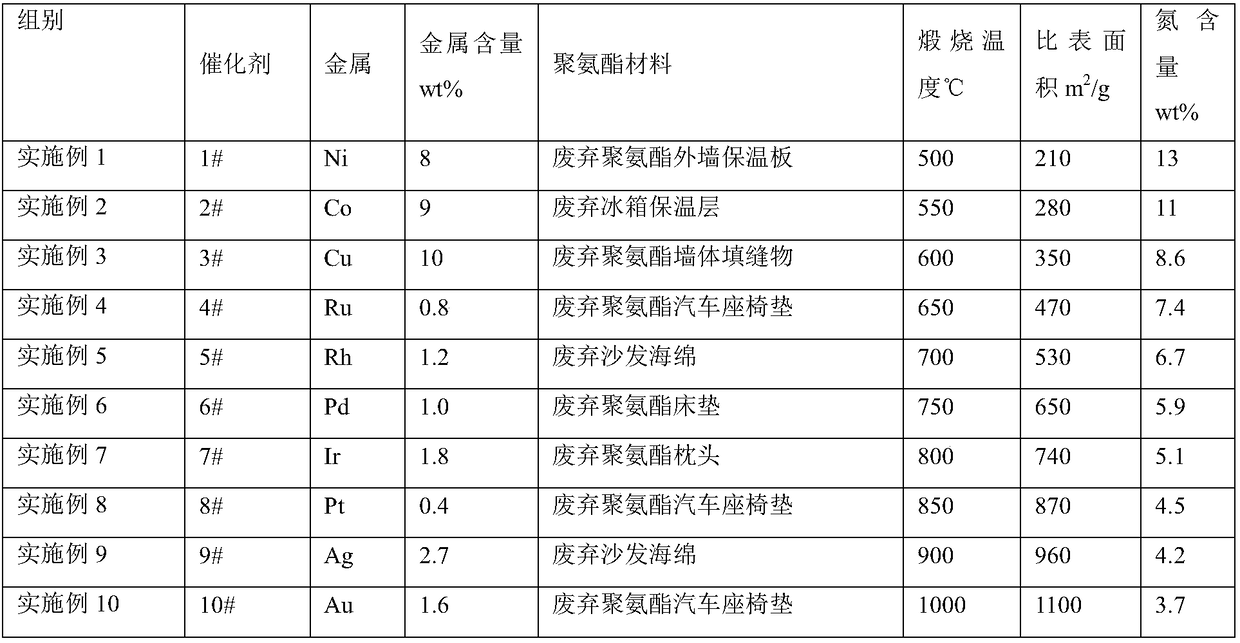

[0043] In Examples 1-10, different metal soluble salts and polyurethane materials were used to prepare catalysts 1#-10# according to the following steps.

[0044] Weigh an appropriate amount of polyurethane material, put it into a tube furnace after crushing, and calcine at the calcination temperature given in Table 1 for 4 hours in a nitrogen atmosphere, and take it out after cooling down to room temperature to obtain a carbonized polyurethane material carrier.

[0045] The carbonized polyurethane material is ground into 100~1000 mesh powders, joins in the metal soluble saline solution containing active component of equal volume (embodiment 1-10 metal soluble salt is successively nickel nitrate, cobalt acetate, copper nitrate, ruthenium chloride , rhodium chloride, palladium chloride, chloroiridic acid, chloroplatinic acid, silver nitrate and chloroauric acid), impregnated for 12h, then dried at 120°C for 24h to obtain a catalyst based on carbonized polyurethane material (cata...

Embodiment 11~20

[0051] Batch kettle

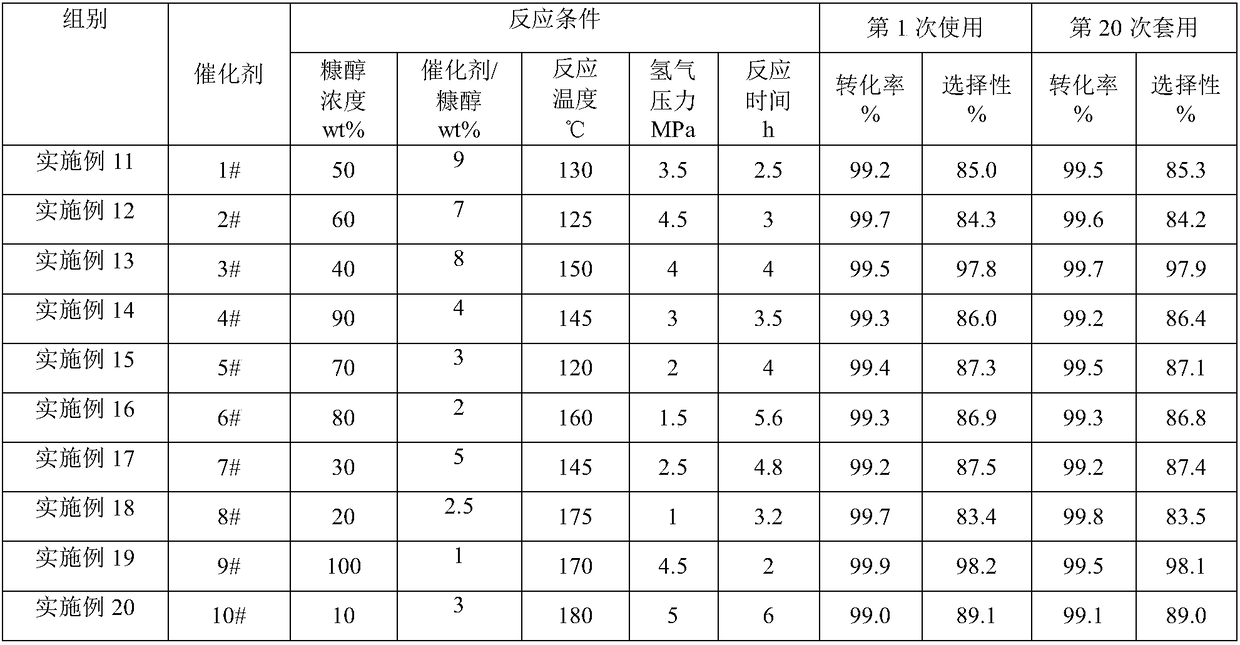

[0052] Embodiment 11-20 is carried out in batch kettle reactor, and batch kettle reactor volume is 3000mL, and material is stainless steel, respectively adopts the 1#-10# catalyst of embodiment 1-10 to prepare cyclopentanone, and raw material furfuryl alcohol is prepared as Furfuryl alcohol aqueous solution or pure furfuryl alcohol.

[0053] Catalyst carries out in-situ reduction in hydrogen: a certain amount of catalyzer is added in above-mentioned batch tank reactor, and the mass percent of the add-on of catalyzer is shown in table 2 with respect to the furfuryl alcohol (furfuryl alcohol aqueous solution in solute meter) to be hydrogenolyzed, The reduction temperature is 200°C, and H is used per 100g of catalyst 2 Flow rate 1.5L / min, H 2 The pressure was 0.3 MPa (gauge pressure), and the catalyst was reduced in situ for 4 hours to activate it.

[0054] Preparation of cyclopentanone: After the catalyst reduction is completed, lower the reaction kettle...

Embodiment 21~30

[0060] fixed bed

[0061] Examples 21-30 were carried out in a fixed bed reactor. The reactor was a stainless steel tube with an outer diameter of 40mm, an inner diameter of 20mm, and a length of 1000mm. The catalysts 1#-10# prepared in Examples 1-10 were used to prepare cyclopentanone.

[0062] The raw material furfuryl alcohol is prepared as furfuryl alcohol aqueous solution or pure furfuryl alcohol before use.

[0063] In situ reduction of the catalyst in hydrogen: 50g of the catalyst is loaded into the reactor, the catalyst is reduced in situ before the reaction, the reduction temperature is 200°C, H 2 The pressure is 0.3MPa, H 2 Flow rate 1.5L / min, reduction 4h.

[0064] Preparation of cyclopentanone: after catalyst reduction, lower to reaction temperature, set hydrogen / catalyst volume space velocity to 1000h -1 , adjust the furfuryl alcohol aqueous solution (or pure furfuryl alcohol) flow rate to the required furfuryl alcohol (in the furfuryl alcohol aqueous solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com