Multi-spectral broadband anticorrosion stealth coating material

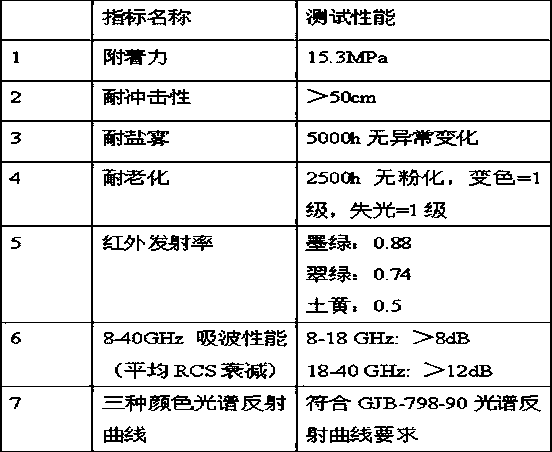

A coating material and anti-corrosion technology, applied in the field of camouflage and stealth, can solve the problems of being unable to resist radar wave detection, far-infrared and radar wave camouflage, etc., to achieve adjustable gel time, improve radar absorbing ability, and construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: the preparation of khaki camouflage paint

[0054] 1. Preparation of Component A

[0055] (1) Add 35 parts of polyaspartic acid ester, 1 part of hyperdispersant, 0.3 part of defoamer, 0.7 part of anti-sedimentation agent, and 25 parts of solvent into a high-speed homogeneous dispersing mixer, at a speed of 1200r / min Stir for 20 minutes to disperse evenly;

[0056] (2) Slowly add 8.6 parts of titanium dioxide powder, 22.5 parts of transparent iron oxide yellow, 4.5 parts of iron oxide red, and 2.4 parts of copper chromium black into step (1) in sequence, and disperse at a high speed of 2000r / min for 30 minutes; make it disperse Uniform;

[0057] (3) Transfer the uniformly dispersed mixture in step (2) to a ball mill, grind to a fineness of ≤30 μm, and filter to obtain component A.

[0058] 2. Preparation of Component B

[0059] Stir 7 parts of HDI, 3 parts of MDI, and 10 parts of solvent at a speed of 1200r / min to obtain component B.

[0060] 3. Coatin...

Embodiment 2

[0062] Embodiment 2: the preparation of medium green camouflage paint

[0063] 1. Preparation of Component A

[0064] (1) Add 35 parts of polyaspartic acid ester, 1 part of hyperdispersant, 0.3 part of defoamer, 0.7 part of anti-settling agent, and 25 parts of solvent into the high-speed homogeneous disperser, at a speed of 1200r / min Stir for 20 minutes to disperse evenly;

[0065] (2) Add 22 parts of chrome green, 1 part of spinel cobalt blue, 5.2 parts of medium chrome yellow, 2.8 parts of ITO powder (tin-doped indium oxide), and 7 parts of titanium dioxide to step (1) in sequence, at 2000r / Disperse at high speed for 30 minutes at a speed of 1 min; make it disperse evenly;

[0066] (3) Transfer the uniformly dispersed mixture in step (2) to a ball mill, grind to a fineness of ≤30 μm, and filter to obtain component A.

[0067] 2. Preparation of Component B

[0068] Stir 7 parts of HDI, 3 parts of MDI and 10 parts of solvent at a speed of 1200r / min to obtain component B. ...

Embodiment 3

[0071] Embodiment 3: the preparation of dark green camouflage paint

[0072] 1. Preparation of component A

[0073] (1) Add 45 parts of polyaspartate, 1 part of hyperdispersant, 0.3 part of defoamer, 0.7 part of anti-sedimentation agent, and 25 parts of solvent into the high-speed homogeneous disperser, at a speed of 800r / min Stir for 20 minutes to disperse evenly;

[0074] (2) Add 18 parts of spinel cobalt green, 2.7 parts of copper chrome black, 1 part of strontium chrome yellow, and 6.3 parts of titanium dioxide into step (1) in order, and disperse at a high speed of 2000r / min for 30 minutes; make it Evenly dispersed;

[0075] (3) Transfer the uniformly dispersed mixture in step (2) to a ball mill, grind to a fineness of ≤30 μm, and filter to obtain component A.

[0076] 2. Preparation of Component B

[0077] Stir 9 parts of HDI, 4 parts of MDI, and 13 parts of solvent at a speed of 1200r / min to obtain component B.

[0078] 3. Coating Preparation

[0079] Mix componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com