Hemt epitaxial structure with multi-quantum well high-resistance buffer layer and preparation method

A high-resistance buffer layer, multi-quantum well layer technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of contaminating the reaction chamber, affecting device characteristics, and decreasing the channel 2DEG mobility, etc. To achieve the effect of strong controllability and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

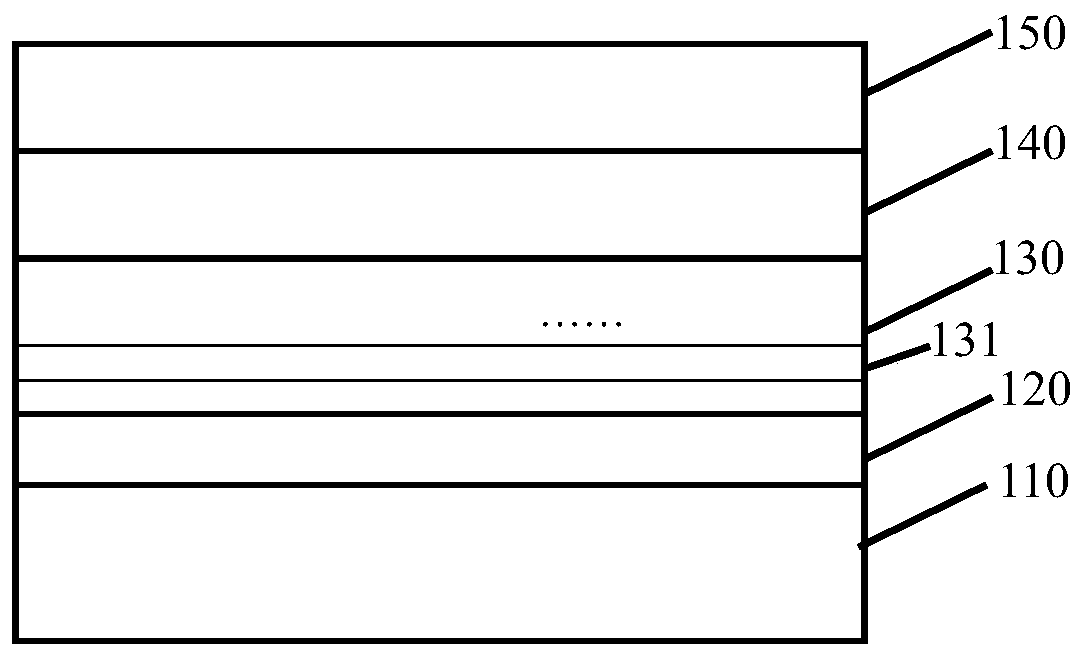

[0050] refer to figure 1 , using p-i-n multiple quantum wells as a high-resistance buffer layer for GaN back barriers on SiC substrates

[0051] (1) An AlN nucleation layer 120 is grown on a 500um 6-inch silicon carbide substrate 110 by MOCVD. Desorption at a high temperature of 1050°C for 10 minutes removes oxides and impurities on the SiC surface, revealing a stepped surface morphology. Then grow the nucleation layer 120 at a high temperature: the growth temperature is 1100° C., the TMAl flow rate is 250 sccm, and the NH 3 The flow rate is 3000sccm, the pressure in the reaction chamber is 70mbar, the growth rate is about 0.3um / h, and the growth time is 30min. The thickness of the AlN nucleation layer 120 is about 150nm;

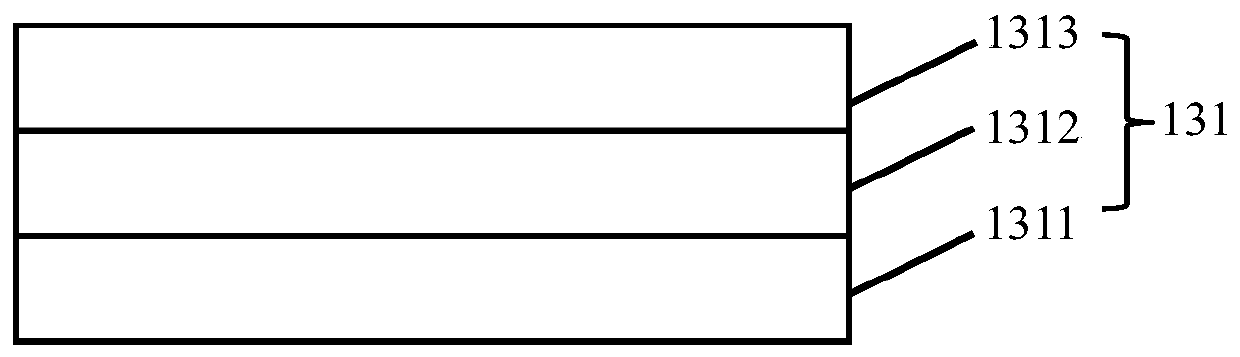

[0052] (2) Continue to grow the p-i-n multi-quantum well layer 130 with an average Al composition of about 5% on the AlN nucleation layer 120 in (1) by MOCVD as the back barrier layer. refer to figure 2 , p-i-n multi-quantum well layer 130 growth incl...

Embodiment 2

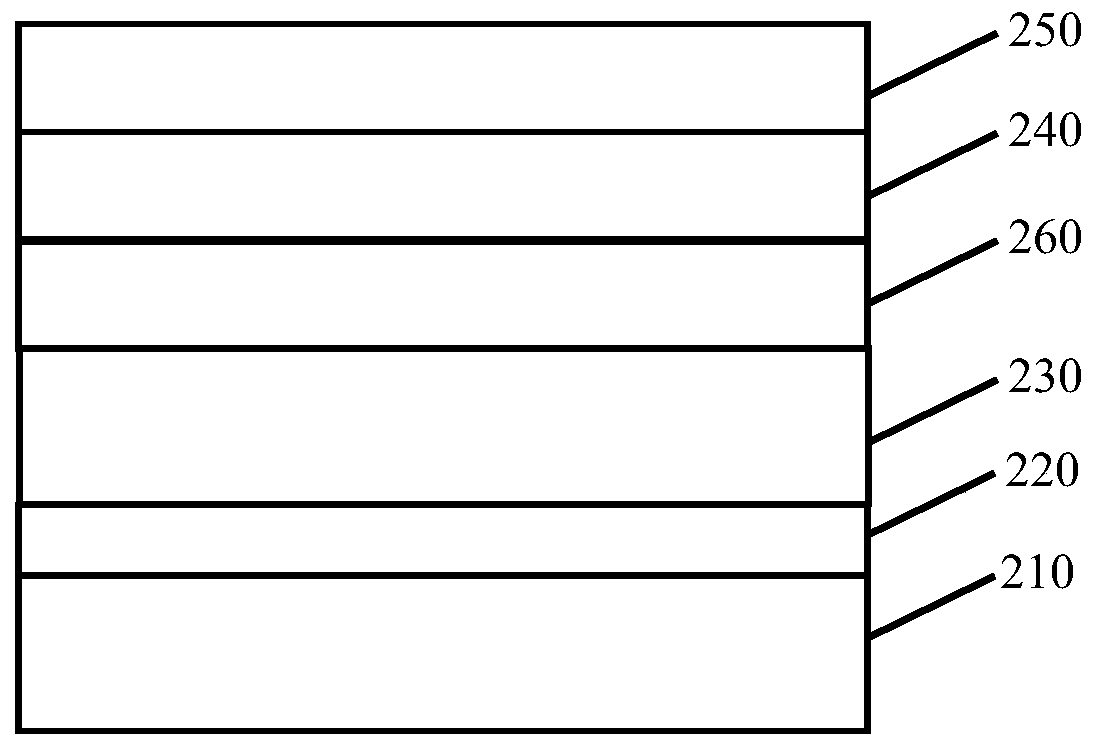

[0056] refer to image 3 , using p-i-n multiple quantum wells as a high-resistance buffer layer for GaN epitaxial stress transfer on Si substrates

[0057] (1) An AlN nucleation layer 220 is grown on a 1mm 6-inch silicon substrate 210 by MOCVD. Desorption at a high temperature of 1050°C for 15 minutes removes oxides and impurities on the Si surface, revealing a stepped surface morphology. Then grow the nucleation layer 220 at high temperature: the growth temperature is 1100° C., the TMAl flow rate is 250 sccm, the NH 3 The flow rate is 3000sccm, the pressure in the reaction chamber is 70mbar, the growth rate is about 0.3um / h, and the growth time is 40min. The thickness of the AlN nucleation layer 220 is about 200nm.

[0058] (2) Continue to grow p-i-n multi-quantum well layer 230 with an average Al composition of about 20% on the AlN nucleation layer 220 in (1) by MOCVD as a high-resistance stress transfer layer. The growth of the p-i-n multi-quantum well layer 230 include...

Embodiment 3

[0063] refer to Figure 4 , using p-i-n multiple quantum wells with graded Al composition as a high-resistance buffer layer for GaN epitaxial stress transfer on Si substrates

[0064] (1) An AlN nucleation layer 320 is grown on a 1mm 6-inch silicon substrate 310 by MOCVD. Desorption at a high temperature of 1050°C for 15 minutes removes oxides and impurities on the Si surface, revealing a stepped surface morphology. Then grow the nucleation layer 320 at high temperature: the growth temperature is 1100° C., the flow rate of TMAl is 250 sccm, the flow rate of NH3 is 3000 sccm, the pressure of the reaction chamber is 70 mbar, the growth rate is about 0.3 um / h, and the growth time is 40 min. The thickness of the AlN nucleation layer 320 is about 200nm.

[0065] (2) Continue to grow p-i-n multi-quantum well layer 330 with an average Al composition of about 72.5% on the AlN nucleation layer 320 of (1) by MOCVD as a high-resistance stress transfer layer. The growth of the p-i-n mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com