Cotton-shaped nitrogen-doped carbon silicon composite electrode material and in-situ preparation method thereof

A carbon-silicon composite and electrode material technology, which is applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, battery electrodes, etc., can solve the problems of difficult control of the microstructure of composite materials and harsh preparation conditions, and achieve low cost and high conditions. Easy-to-control, fast-response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides an in-situ preparation method of a nitrogen-doped flocculent carbon-silicon composite electrode material, which is carried out according to the following steps:

[0038] S01: Weigh 400 mg silicon carbide powder (purity 99.9%, particle size 0.3-4 μm) into a beaker, add 15 mL deionized water and 5 mL ammonia water (analytical grade, Aladdin, 0.91 g mL -1 ) to fully stir to obtain a suspension dispersion;

[0039] S02: Put the above-mentioned suspension and dispersion in an ice-bath ultrasonic tank for ultrasonic dispersion, the ultrasonic power is 80 W, and at the same time, the argon-fluorine laser beam (193 nm) has an energy density of 0.9 J pulse -1 cm -1 , irradiated by a laser with a frequency of 5 Hz for 10 min;

[0040] S03: After the irradiation, freeze-dry the suspension to obtain nitrogen-doped flocculent carbon-silicon composite electrode material.

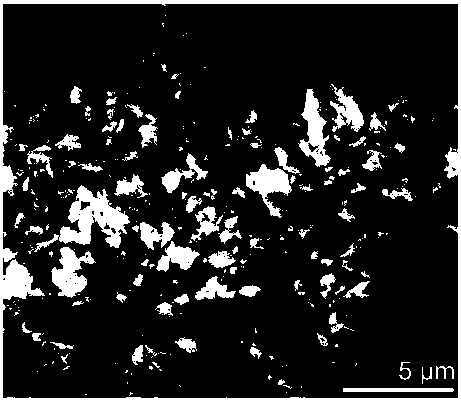

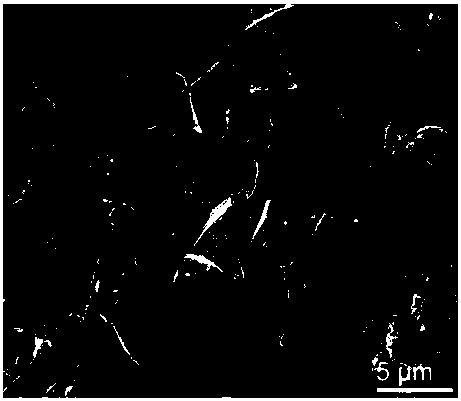

[0041] figure 1 It is a scanning electron microscope image of the original silicon ...

Embodiment 2

[0048] This embodiment provides an in-situ preparation method of a nitrogen-doped flocculent carbon-silicon composite electrode material, which is carried out according to the following steps:

[0049] S01: Weigh 200 mg silicon carbide powder (purity 99.9%, particle size 0.01-1 μm) into a beaker, add 18 mL deionized water and 2 mL ammonia water (analytical grade, Aladdin, 0.91 g mL -1 ), to obtain a suspension dispersion;

[0050] S02: Put the above-mentioned suspension and dispersion liquid in an ice-bath ultrasonic tank for ultrasonic dispersion, the ultrasonic power is 300 W, and at the same time, the krypton-fluorine laser beam (248 nm) has an energy density of 0.5 J pulse -1 cm -1 , irradiated by laser with a frequency of 8 Hz for 30 min;

[0051] (3) After irradiation, freeze-dry the suspension to obtain nitrogen-doped flocculent carbon-silicon composite electrode material.

[0052] The particle size of silicon particles in the obtained flocculent carbon-silicon compo...

Embodiment 3

[0054] This embodiment provides an in-situ preparation method of a nitrogen-doped flocculent carbon-silicon composite electrode material, which is carried out according to the following steps:

[0055] S01: Weigh 50 mg silicon carbide powder (purity 99.9%, particle size 40-50 μm) into a beaker, add 19 mL deionized water and 1 mL ammonia water (analytical grade, Aladdin, 0.91 g mL -1 ), to obtain a suspension dispersion;

[0056] S02: Put the above-mentioned suspension and dispersion in an ice-bath ultrasonic tank for ultrasonic dispersion, the ultrasonic power is 500 W, and at the same time, the Xenon-Chlorine laser beam (308 nm) has an energy density of 0.9 J pulse -1 cm -1 , irradiated by a laser with a frequency of 10 Hz for 50 min;

[0057] S03: After the irradiation, freeze-dry the suspension to obtain nitrogen-doped flocculent carbon-silicon composite electrode material.

[0058] The particle size of silicon particles in the obtained flocculent carbon-silicon composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com