Injectable organosilicone/chitosan nanocomposite hydrogel as well as preparation method and application thereof

A chitosan nano-composite hydrogel technology, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., can solve the problems of poor mechanical strength and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

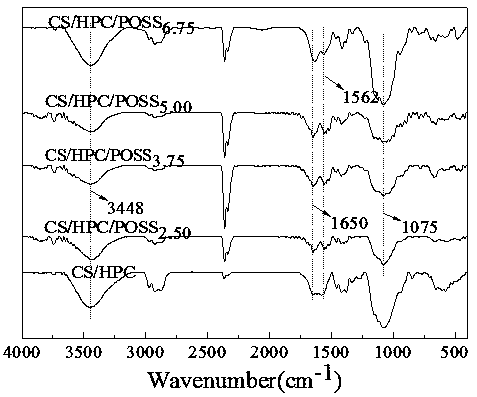

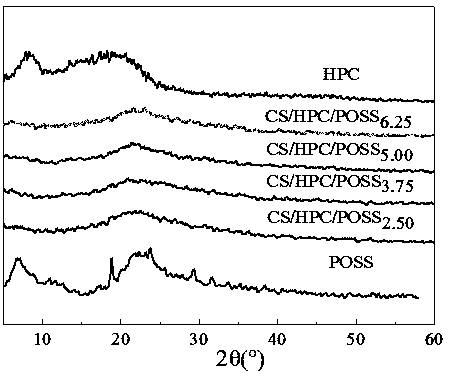

Embodiment 1

[0019] Octapolyammonium chloride propyl polysilsesquioxane (OCAPS): 30 mL of 3-aminopropyltriethoxysilane (KH550) and 27 mL of concentrated hydrochloric acid were sequentially added to 200 mL of anhydrous methanol In a single-necked bottle, magnetically stirred at room temperature, a white precipitate was produced during the reaction, and after one week, the resulting product was suction filtered, 40 o C was dried in vacuum for 24 hours to obtain water-soluble POSS, namely octamer ammonium chloride propyl polysilsesquioxane (OCAPS).

Embodiment 2

[0021] CS / HPC / OCAPS 2.50 The preparation of nanocomposite hydrogel: take by weighing 0.20g chitosan and be dissolved in 4ml mass fraction and be 1% in the acetic acid solution of mass fraction, be mixed with the chitosan acetic acid solution that mass fraction is 5%, add to the chitosan acetic acid solution then Add 0.10g of OCAPS; weigh 0.30g of hydroxypropyl cellulose and dissolve it in 4ml of deionized water until it is completely dissolved, then mix the fully dissolved hydroxypropyl cellulose solution with chitosan solution evenly, 37 o C A ternary composite hydrogel was prepared by reacting in a constant temperature water bath for 24 hours.

[0022] CS / HPC / OCAPS of this embodiment 2.50 Nanocomposite hydrogel, wherein the meaning of 2.50 refers to the mass fraction of OCAPS in the chitosan-acetic acid solution, that is, 2.5wt%, the same below.

Embodiment 3

[0024] CS / HPC / OCAPS 3.75 Preparation of nanocomposite hydrogel: Weigh 0.2g chitosan and dissolve it in 4ml acetic acid solution with a mass fraction of 1wt%, to prepare a chitosan acetic acid solution with a mass fraction of 5 wt%, and then add chitosan acetic acid solution Add 0.15g of OCAPS to it. Weigh 0.3g of formylated hydroxypropyl cellulose and dissolve it in 4ml of deionized water until it is completely dissolved, then mix the fully dissolved formylated hydroxypropyl cellulose solution and chitosan solution evenly, 37 o C A ternary composite hydrogel was prepared by reacting in a constant temperature water bath for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com