Coke oven gas hydrogenation and desulfurization catalyst and method for preparing same

A technology for hydrodesulfurization and coke oven gas, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve problems such as environmental pollution, and achieve environmental friendliness , the method is simple, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

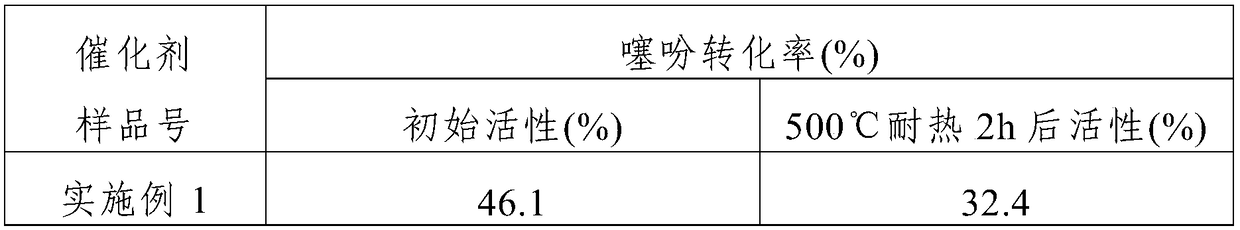

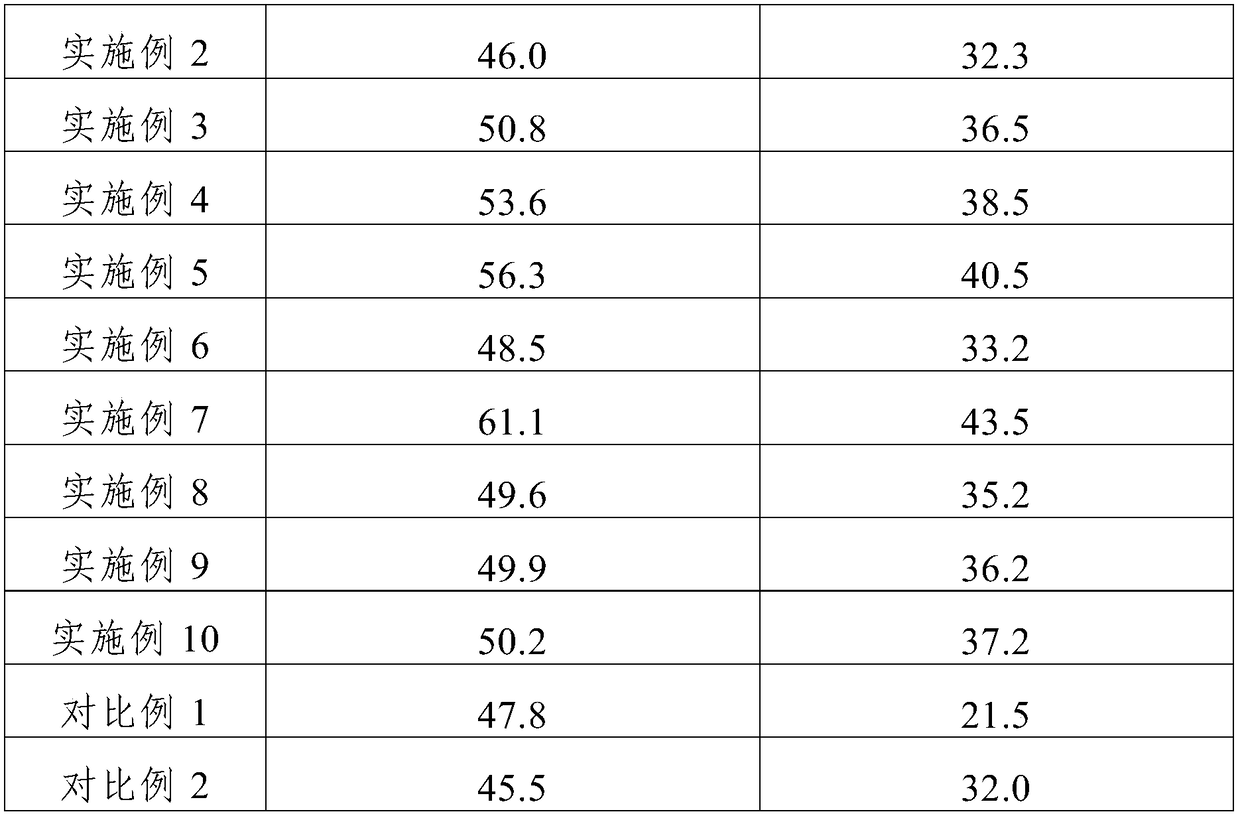

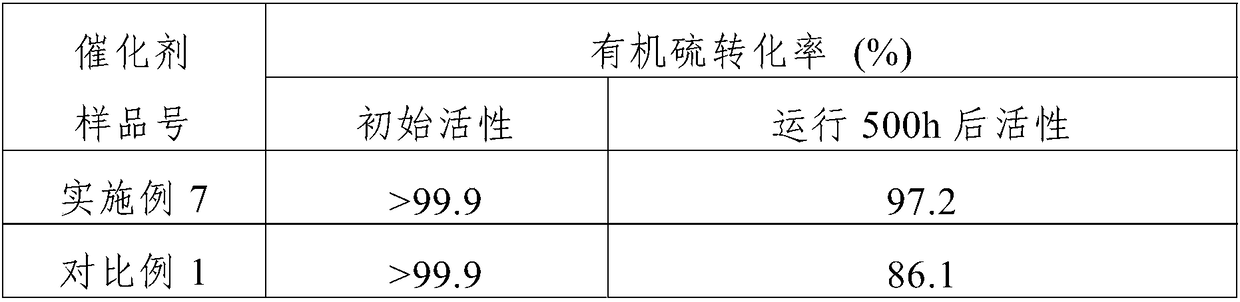

Examples

Embodiment 1

[0028] The coke oven gas hydrodesulfurization catalyst of the present embodiment is made of the raw material of following mass percent: SiO 2 0.1%, B 2 o 3 0.1%, MoO 3 8.0%, Al 2 o 3 91.8%; the preparation method of this coke oven gas hydrodesulfurization catalyst is: take by weighing ammonium dimolybdate 18.9g and be dissolved in 110g water, add 0.5g tetramethoxysilane after dissolving, add sulfuric acid 0.30g, boric acid 0.04g, add 184g of alumina carrier, dry at 120°C for 12h after impregnation, and then calcinate at 500°C for 2h to obtain the finished catalyst.

Embodiment 2

[0030] The coke oven gas hydrodesulfurization catalyst of the present embodiment is made of the raw material of following mass percent: SiO 2 0.1%, P 2 o 5 0.1%, MoO 3 8.0%, Al2 o 3 91.8%; the preparation method of this coke oven gas hydrodesulfurization catalyst is: take by weighing ammonium dimolybdate 18.9g and be dissolved in 110g water, add 0.25g tetramethoxysilane and 0.2g trimethoxysilane after dissolving, under stirring condition Add 0.30g of sulfuric acid and 0.03g of phosphoric acid, add 184g of alumina carrier, dry at 120°C for 12h after impregnation, and then roast at 500°C for 2h to obtain the finished catalyst.

Embodiment 3

[0032] The coke oven gas hydrodesulfurization catalyst of the present embodiment is made of the raw material of following mass percent: SiO 2 1.0%, B 2 o 3 0.2%, MoO 3 9.0%, Al 2 o 3 89.8%.

[0033] The preparation method of this coke oven gas hydrodesulfurization catalyst is: take by weighing ammonium tetramolybdate 19.6g and add in 90g water, adjust solution pH with ammonia water to be 9 and make ammonium tetramolybdate dissolve, then add 6.9g tetraethoxysilane, in Add 8.0 g of nitric acid, 0.7 g of boric acid, and 180 g of alumina carrier under stirring conditions. After impregnation, dry at 120°C for 12 hours, and then roast at 300°C for 10 hours to obtain a finished catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com