Preparation and application of ordered mesoporous phenolic resin polymer silver-loaded catalyst

A technology of phenolic resin and silver catalyst, applied in the field of chemical catalytic materials and chemical applications, can solve the problems of complex preparation process of catalyst carrier, application limitation of homogeneous catalyst, application limitation of metal catalyst, etc. Good chemical stability and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

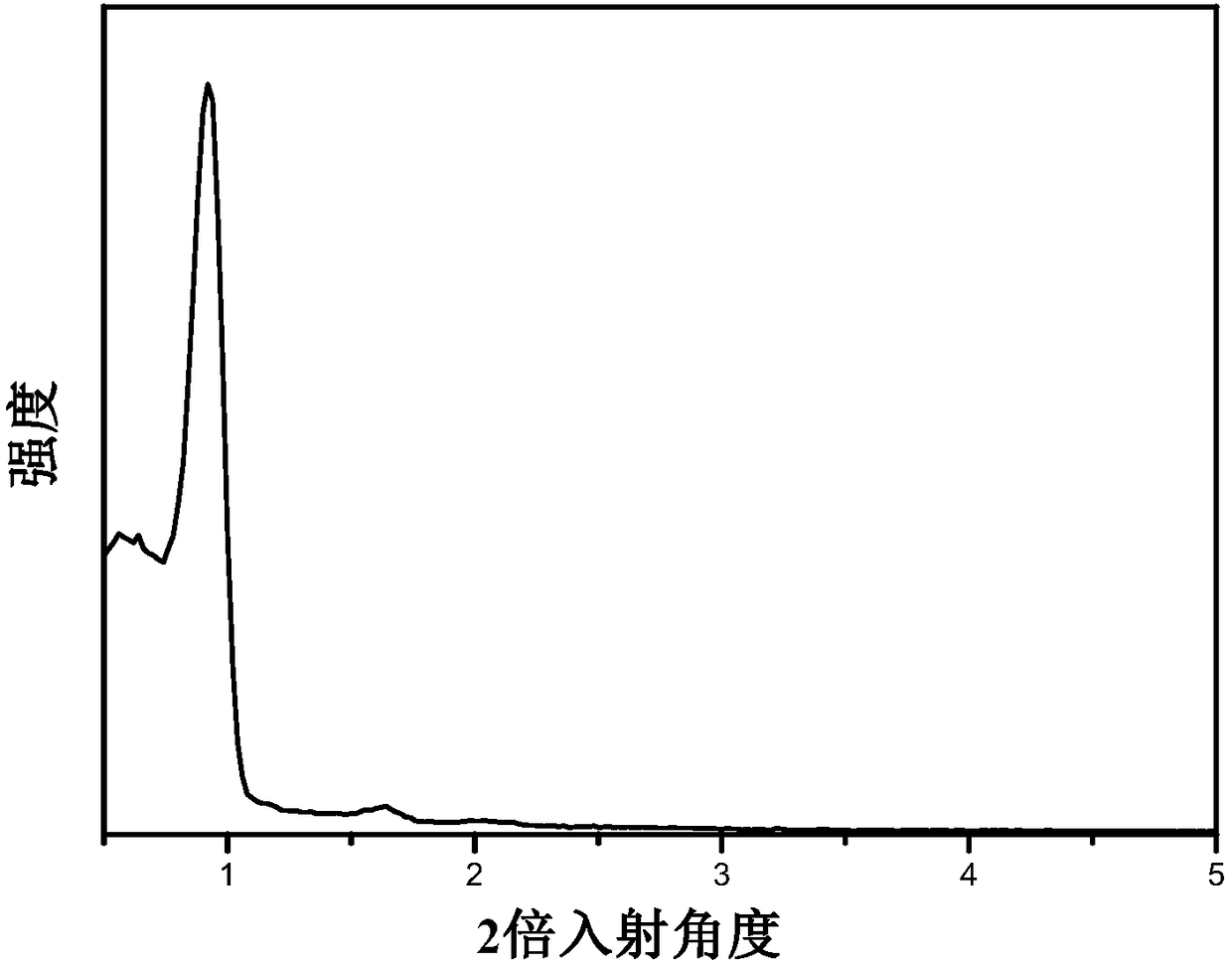

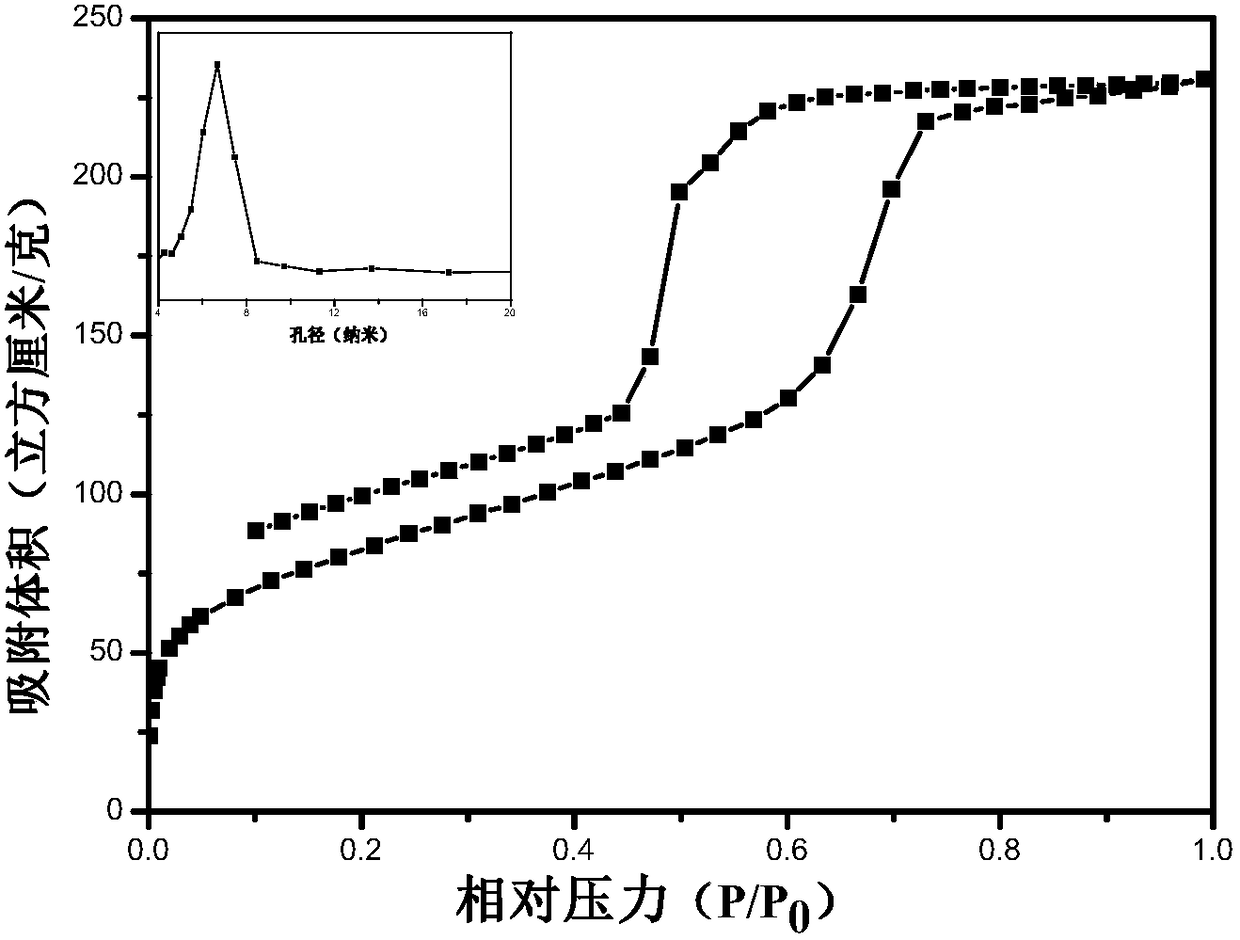

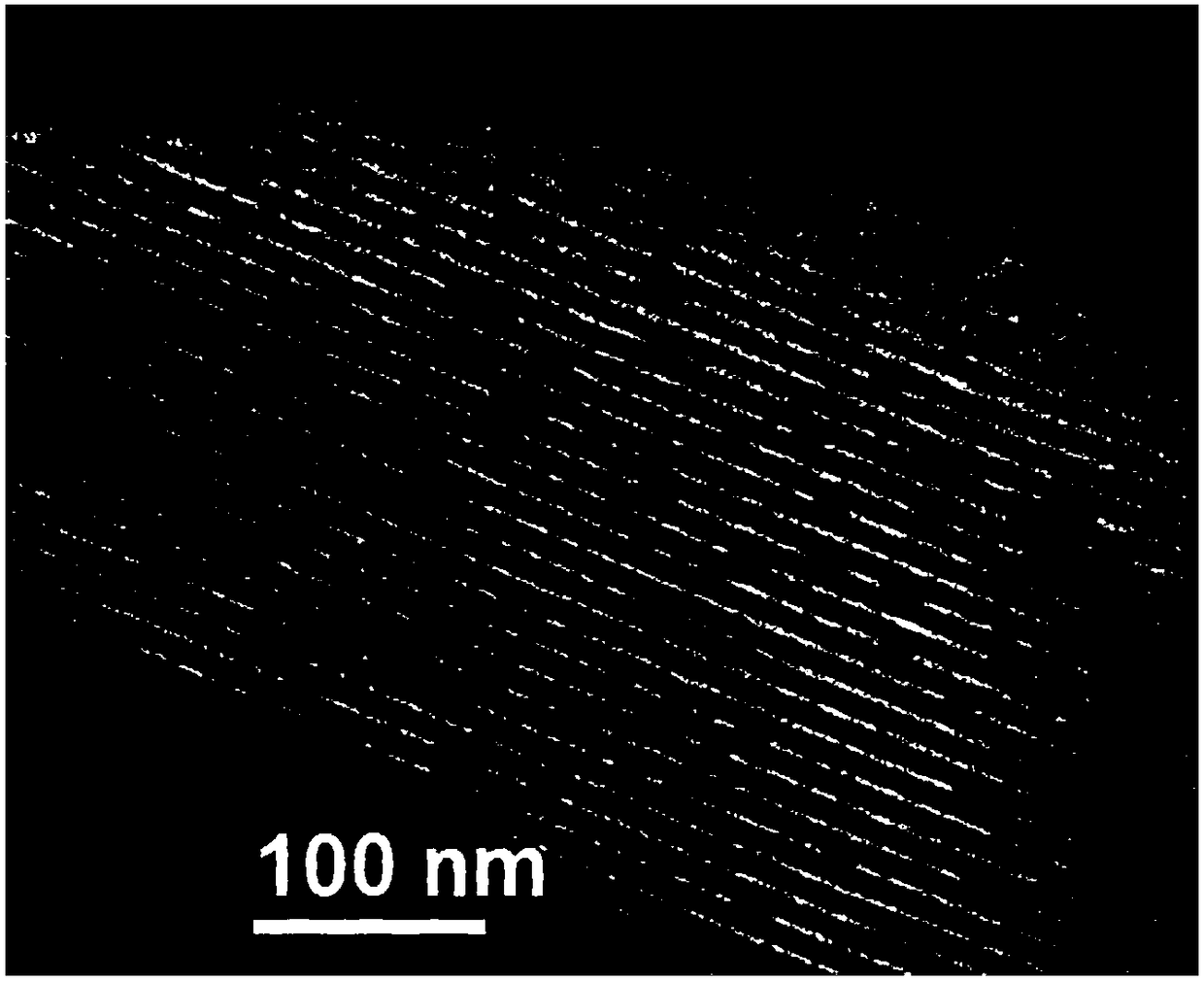

[0026] (1) Chloromethylation of ordered mesoporous materials

[0027] Under the conditions of ice-water bath and argon protection, mix and stir 4g FDU mesoporous phenolic resin and 20g chloromethyl methyl ether, and add 29g of anhydrous aluminum chloride in three times, react under ice-water bath conditions for 24 hours, and the reaction ends Then add deionized water to quench the unreacted anhydrous aluminum chloride, wash with 300ml deionized water and 200ml acetone alternately three times after suction filtration, and then dry in a vacuum oven at 80°C for 24 hours to obtain chloromethyl FDU mesoporous phenolic resin.

[0028] (2) Amine functionalization of chloromethylated FDU mesoporous phenolic resin

[0029] Mix 4g of chloromethylated FDU mesoporous phenolic resin with 20g of methylamine, add 100ml of acetonitrile solution, and react at 83°C for 8 hours. After the reaction, the filtrate is alternately washed three times with 200ml of acetone and 300ml of deionized water...

Embodiment 2

[0036] (1) Chloromethylation of ordered mesoporous materials

[0037] Under the conditions of ice-water bath and argon protection, mix and stir 4g FDU mesoporous phenolic resin and 20g chloromethyl methyl ether, and add 29g of anhydrous aluminum chloride in three times, react under ice-water bath conditions for 24 hours, and the reaction ends Then add deionized water to quench the unreacted anhydrous aluminum chloride, wash three times alternately with 300ml deionized water and 200ml acetone after suction filtration, and then dry in a vacuum oven at a temperature of 80°C for 24 hours to obtain chloromethyl FDU mesoporous phenolic resin.

[0038] (2) Amine functionalization of chloromethylated FDU mesoporous phenolic resin

[0039] Mix 4g of chloromethylated FDU mesoporous phenolic resin with 20g of dimethylamine, add 100ml of acetonitrile solution, and react at 83°C for 8 hours. After the reaction, the filtrate is alternately washed three times with 200ml of acetone and 300ml...

Embodiment 3

[0046] 489mg (1.5mmol) cesium carbonate and 50mg (0.1mol%) the silver nano-loaded metal catalyst (FDU-Ag) that embodiment 1 prepares is put into the three-necked flask of 50ml, and carbon dioxide is filled in the balloon, to device Vacuumize and ventilate three times to fully remove the air in the device, then weigh 102 mg of phenylacetylene (1 mmol) with a syringe and extract 10 ml of anhydrous DMF solution into the device, heat to 50 ° C, and react for 18 hours. The reaction structure is:

[0047]

[0048] CO during the reaction 2 Pressure is atmospheric pressure all the time, after reaction finishes, flask is cooled to room temperature, mixed solution is carried out suction filtration and washes and separates catalyst with the deionized water of 20ml, adds the dichloromethane of 90ml in filtrate and carries out extraction three times and takes water layer, in separated Add dilute hydrochloric acid to the water layer to adjust the pH to 1, then extract with 60ml of ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com