AlMgB14-TiB2/Ti gradient functional composite and preparation method thereof

A technology of almgb14-tib2 and gradient function, which is applied in the field of composite material preparation, can solve the problems of limited application range and low toughness, and achieve the effect of ensuring reaction strength, good heat resistance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

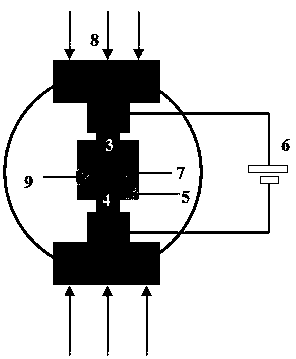

[0024] Such as Figure 1-2 As shown, an AlMgB 14 -TiB 2 The preparation method of Ti / Ti gradient function composite material comprises following preparation steps:

[0025] (1) AlMgB 14 Ceramic powder, Ti metal powder, TiB 2 The powder is subjected to ultrasonic dispersion treatment in ethanol for 1h;

[0026] (2) Place the above-mentioned powders after ultrasonic dispersion in a drying oven for 2 hours;

[0027] (3) Take the dried TiB 2 Powder added to AlMgB 14 Mix evenly with ceramic powder, and place it in a corundum ball mill jar for ball milling for 10 hours to form AlMgB 14 -TiB 2 mixed powder;

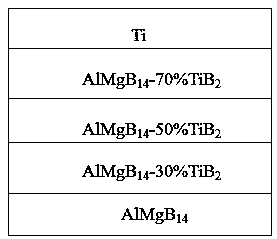

[0028] (4) Ti metal powder, AlMgB 14 -TiB 2 Mixed powder, AlMgB 14 The ceramic powder is stacked in the silicon carbide mold tube 5;

[0029] (5) Place the silicon carbide mold tube 5 between the upper graphite indenter 3 and the lower graphite indenter 4 in the reaction furnace and apply pressure to press into a columnar blank;

[0030] (6) Vacuumize the reaction ...

Embodiment 1

[0034] The mass fractions were 20%, 40% and 60% of TiB 2 Join AlMgB 14 Mix evenly, and mill in a corundum ball mill jar for 10 hours for later use. In the mold, place Ti metal powder, AlMgB 14 with TiB 2 mixed powder, AlMgB 14 Ceramic powder, the middle layer is 3 layers. Place the mold in a press, and press it into a columnar billet with a pressure of 15 MPa. AlMgB 14 The particle size of ceramic powder and Ti metal powder is 30-50μm, TiB 2 The particle size of the powder is 200nm, and the powder is subjected to ultrasonic dispersion treatment in ethanol for 1 hour and dried in a drying oven for 2 hours before mixing.

[0035] Such as figure 1 As shown, place the billet in the silicon carbide mold tube between the electrodes, increase the current with a pulse frequency of 40Hz to 1500A, keep it for 10min, then drop it to 1200A, keep it for 15min, and finally turn off the power, and the sample is cooled to room temperature with the furnace. The vacuum degree in the fu...

Embodiment 2

[0037] The mass fractions were 30%, 50% and 70% of TiB 2 Join AlMgB 14 Mix evenly, and mill in a corundum ball mill jar for 10 hours for later use. In the mold, place Ti metal powder, AlMgB 14 with TiB 2 mixed powder, AlMgB 14 Ceramic powder, the middle layer is 3 layers. Place the mold in a press, and press it into a columnar billet with a pressure of 15 MPa. AlMgB 14 The particle size of ceramic powder and Ti metal powder is 30-50μm, TiB 2 The particle size of the powder is 200nm, and the powder is subjected to ultrasonic dispersion treatment in ethanol for 1 hour and dried in a drying oven for 2 hours before mixing.

[0038] Such as figure 1 As shown, place the blank in the silicon carbide mold tube between the electrodes, increase the current with a pulse frequency of 50Hz to 1500A, keep it for 10min, then drop it to 1300A, keep it for 15min, and finally turn off the power, and the sample is cooled to room temperature with the furnace. The vacuum degree in the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com