Preparation method of high-thermal-conductivity silicone rubber containing aluminum nitride/graphene hybrid material

A technology of hybrid materials and aluminum nitride, which is applied in the field of preparation of high-performance polymer materials, can solve problems such as poor mechanical properties, achieve good toughness, improve compatibility, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

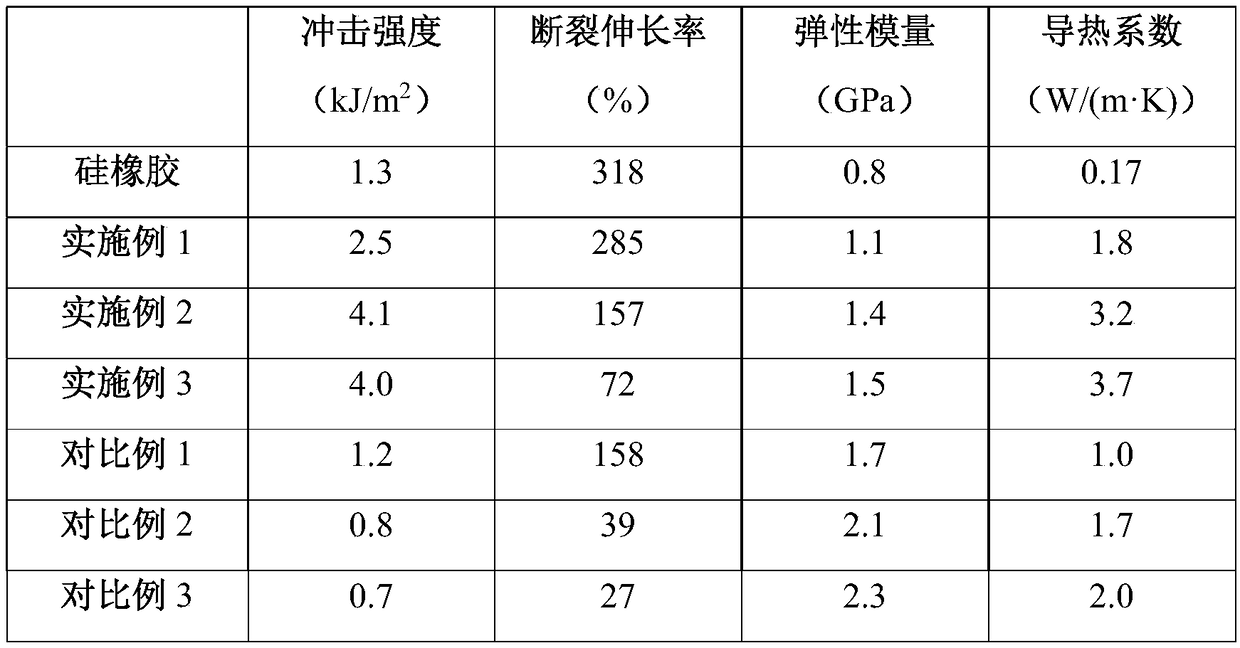

Examples

Embodiment 1

[0024] (1) Add 1g of 3-aminopropyltriethoxysilane modified aluminum nitride and 2mg of glycidyl 3-trimethoxysilyl propyl ether modified graphene into 50mL of toluene, and after ultrasonication at room temperature for 15min, Raise the temperature to 70°C, react for 12 hours, filter the product, wash with ethanol, and dry it in vacuum at 60°C for 24 hours to prepare aluminum nitride / graphene hybrid material;

[0025] (2) Add 25 parts of the hybrid material prepared in step (1), 6 parts of aromatic hydrocarbon oil, and 3 parts of N-phenyl-α-naphthylamine to 100 parts of silicone rubber, and use a double-roll mill to mix at room temperature Refined for 30 minutes, and left at room temperature for 24 hours to prepare the mixed rubber;

[0026] (3) The mixed rubber prepared in step (2) is thin-passed 4 times at room temperature using a two-roll mill, and 3 parts of dicumyl peroxide are added in the thin-pass process, and vulcanized by a flat vulcanizer. The temperature is 100°C, th...

Embodiment 2

[0028] (1) Add 5g of 3-aminopropyltriethoxysilane modified aluminum nitride and 25mg of glycidyl 3-trimethoxysilyl propyl ether modified graphene into 90mL of toluene, and after ultrasonication at room temperature for 20min, Raise the temperature to 80°C, react for 8h, filter the product, wash with ethanol, and vacuum dry at 60°C for 12h to prepare aluminum nitride / graphene hybrid material;

[0029] (2) Add 40 parts of the hybrid material prepared in step (1), 7 parts of paraffin, and 4 parts of N-phenyl-N'-cyclohexyl-p-phenylenediamine to 100 parts of silicone rubber, and use double rollers at room temperature Mix in the open mill for 30 minutes, and place at room temperature for 24 hours to prepare the mixed rubber;

[0030] (3) Utilize the two-roller open mill to thinly pass the mixed rubber prepared in step (2) at room temperature for 6 times, add 2 parts of benzoyl peroxide in the thinly passed process, and utilize a flat vulcanizer to vulcanize, and the vulcanization tem...

example example 3

[0032] (1) Add 10g of 3-aminopropyltriethoxysilane modified aluminum nitride and 200mg of glycidyl 3-trimethoxysilyl propyl ether modified graphene into 300mL of toluene, and after ultrasonication at room temperature for 30min, Raise the temperature to 90°C, react for 4 hours, filter the product, wash with ethanol, and vacuum dry at 60°C for 24 hours to prepare aluminum nitride / graphene hybrid materials;

[0033] (2) Add 55 parts of the hybrid material prepared in step (1), 9 parts of vaseline, and 6 parts of calcium-zinc composite stabilizer to 100 parts of silicone rubber in turn, and knead for 60 minutes at room temperature using a double-roller mill. Leave it for 24 hours to prepare the mixed rubber;

[0034] (3) The mixed rubber prepared in step (2) is passed 8 times at room temperature using a two-roll mill, and 1 part of 2,4-dichlorobenzoyl peroxide is added during the thin pass, and vulcanized by a flat plate machine for vulcanization, the vulcanization temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com