A kind of fe-a12o3 cermet sealing ring and preparation method thereof

A technology of fe-a12o3 and cermet, which is applied in the field of cermet materials, can solve the problems of affecting the working stability, the sealing parts are fragile and easy to crack, and the uniformity of toughness and microstructure is insufficient, so as to improve the wear resistance and improve the Hardness and mechanical strength, the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

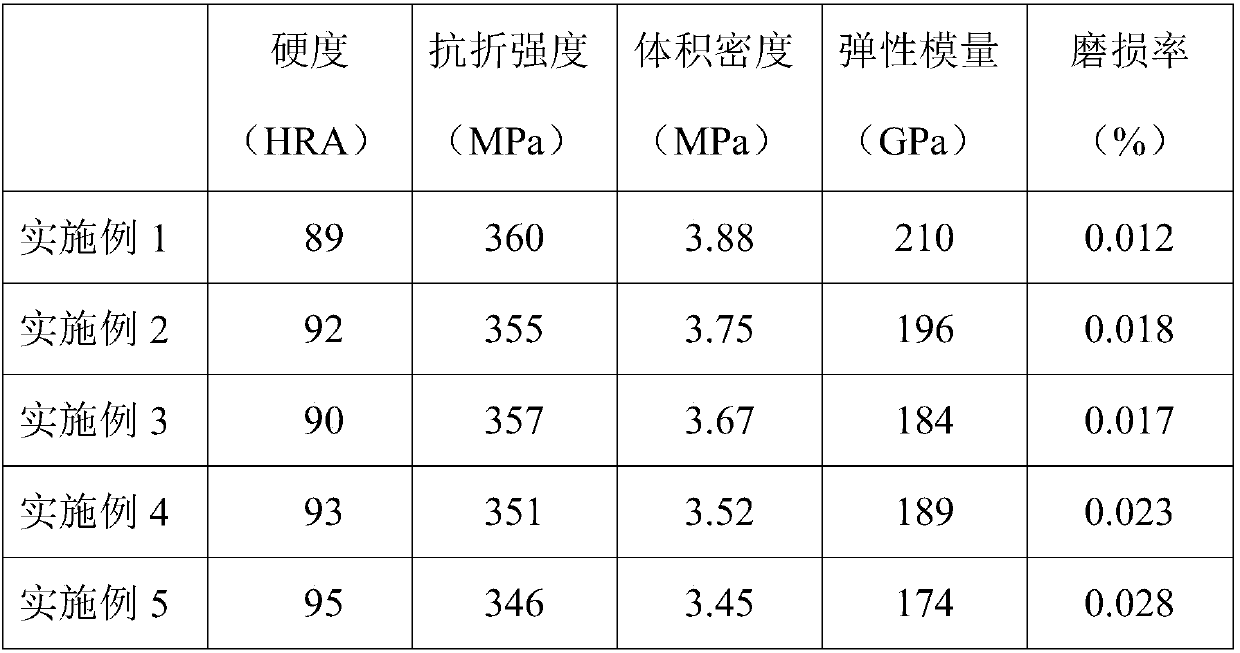

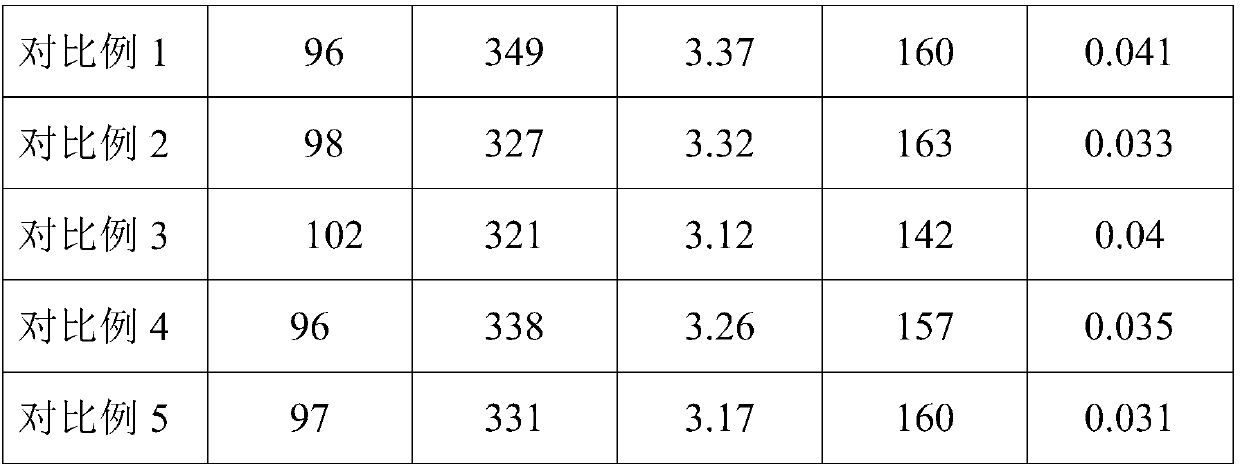

Examples

Embodiment 1

[0038] a Fe-A1 2 o 3 A cermet sealing ring consisting of the following components in weight percent: aluminum oxide 50%, iron oxide 3%, zirconium oxide 2.2%, cerium oxide 4%, LaNbO 4 : 0.6%, Aluminate 1.5%, Calcium Carbonate 0.3%, Magnesium Carbonate 0.4%, Wax Emulsion 0.25%, Polymethacrylate Ammonium 0.7%, Ethyl Acrylate 0.6%, Methylcellulose 0.7%, Polyethylene 0.2% alcohol, 0.2% triammonium citrate, 0.4% gum arabic, and the balance is clay and irremovable impurities.

[0039] According to the above Fe-A1 2 o 3 The components of the cermet sealing ring are weighed as raw materials, and aluminum oxide, iron oxide, zirconium oxide, cerium oxide, LaNbO 4 , aluminate, calcium carbonate, and magnesium carbonate were stirred and mixed evenly, and transported to a ball mill with a rotating speed of 250r / min for wet grinding for 3 hours to obtain powder, wherein the ball-to-material ratio was 3:1, and the solid-to-liquid ratio was 1:1;

Embodiment 2

[0045] a Fe-A1 2 o 3 A cermet seal ring consisting of the following components in weight percent: alumina: 48%, iron oxide: 2.8%, zirconia: 2.6%, ceria: 4.2%, LaNbO 4 : 0.4%, Aluminate: 1.3%, Calcium Carbonate: 0.4%, Magnesium Carbonate: 0.5%, Wax Emulsion 0.15%, Ammonium Polymethacrylate 0.5%, Ethyl Acrylate 0.3%, Methyl Cellulose 1.2% , triammonium citrate 0.7%, and the balance is clay and irremovable impurities.

[0046] According to the above Fe-A1 2 o 3 Component composition of cermet sealing ring Weigh raw materials, aluminum oxide, iron oxide, zirconium oxide, cerium oxide, LaNbO 4 , aluminate, calcium carbonate, and magnesium carbonate were stirred and mixed evenly, and were transported to a ball mill with a rotating speed of 230r / min for wet grinding for 3.5h to obtain powder, wherein the ball-to-material ratio was 2:1, and the solid-to-liquid ratio was 1.5:1;

[0047] Mix the obtained powder with wax emulsion and ammonium polymethacrylate at 110°C for 50 minutes...

Embodiment 3

[0052] a Fe-A1 2 o 3 A cermet seal ring consisting of the following components in weight percent: alumina: 52%, iron oxide: 3.1%, zirconia: 2.2%, ceria: 4.6%, LaNbO 4 : 0.8%, aluminate: 1.7%, calcium carbonate: 0.2%, magnesium carbonate: 0.3%, wax emulsion 0.07%, ammonium polymethacrylate 0.8%, polyvinyl alcohol 0.7%, methylcellulose 0.2% , gum arabic 0.8%, and the balance is clay and irremovable impurities.

[0053] According to the above Fe-A1 2 o 3 Component composition of cermet sealing ring Weigh raw materials, aluminum oxide, iron oxide, zirconium oxide, cerium oxide, LaNbO 4 , aluminate, calcium carbonate, and magnesium carbonate were evenly mixed, and transported to a ball mill with a rotating speed of 260r / min for wet milling for 4h to obtain powder, wherein the ball-to-material ratio was 2.5:1, and the solid-to-liquid ratio was 1.5:1;

[0054] Mix the obtained powder with wax emulsion and ammonium polymethacrylate at 115°C for 50 minutes, then spray granulate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com