Polytriphenylamine-carbon nanofiber composite material, and preparation method and application thereof

A technology of carbon nanofiber and polytriphenylamine, which is applied in the direction of carbon fiber, fiber treatment, fiber chemical characteristics, etc., can solve the problems affecting the full utilization of active substances, etc., and achieve the effect of easy operation, excellent performance and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

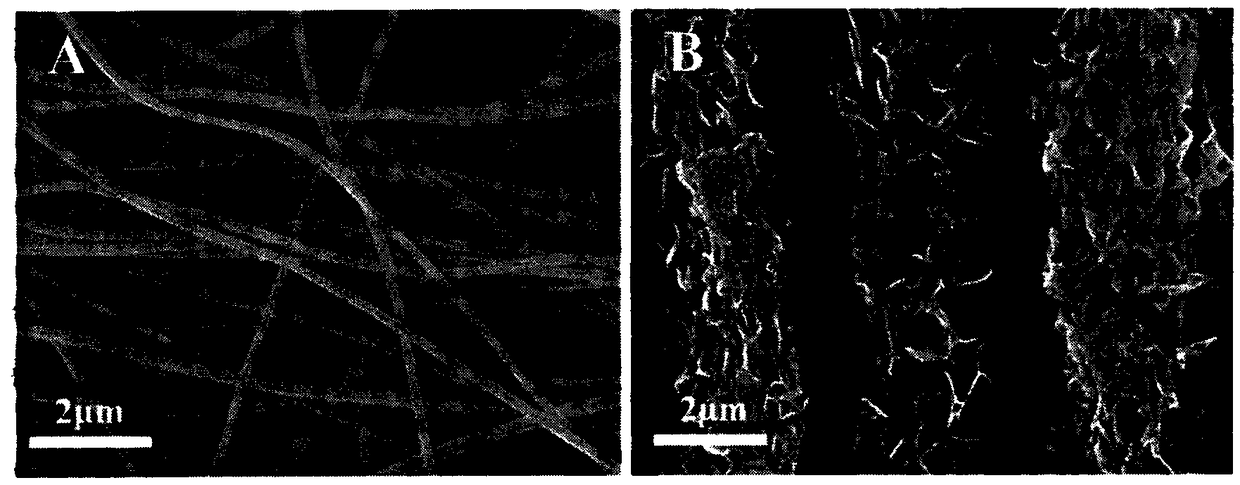

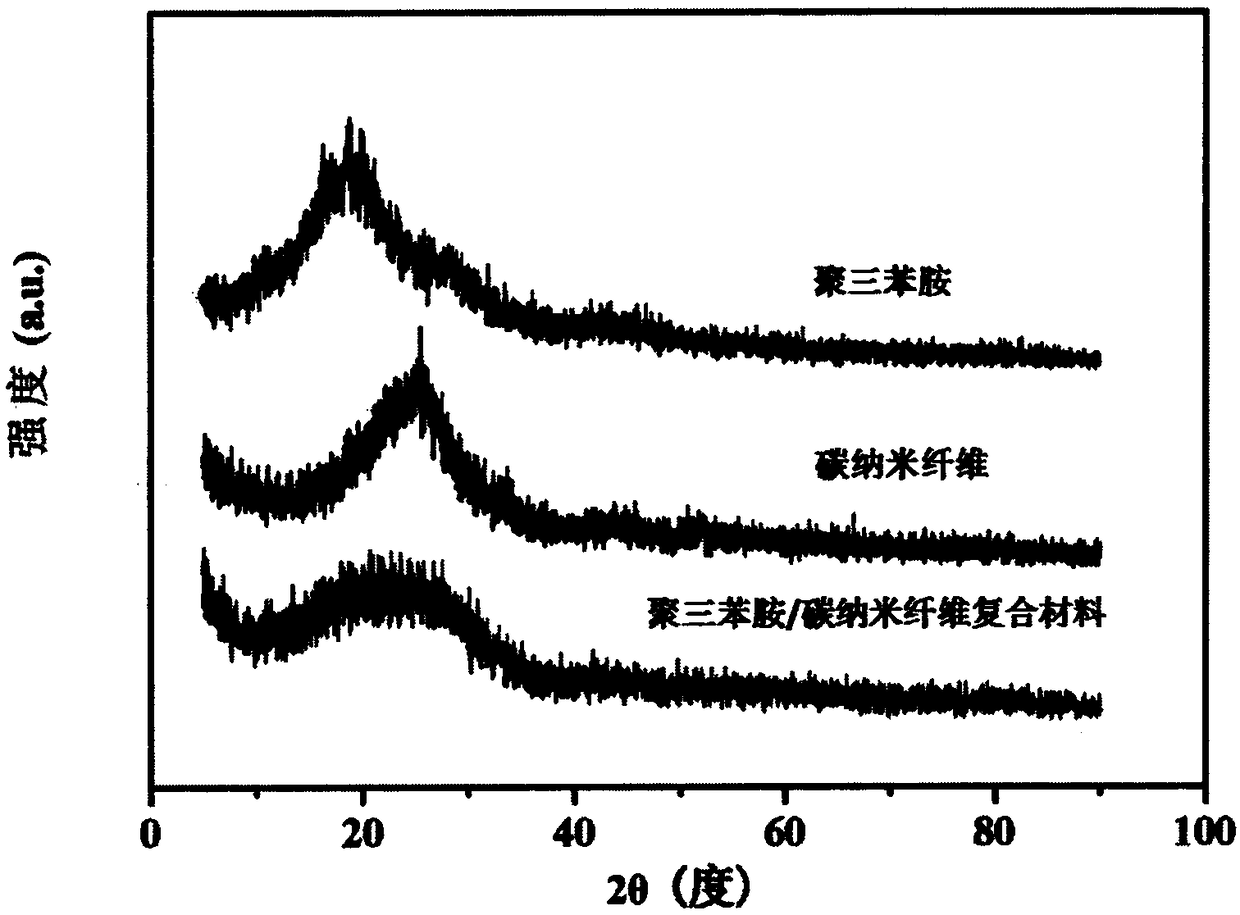

[0033] A kind of preparation method of polytriphenylamine-carbon nanofiber composite material, concrete steps are:

[0034] Step 1: Prepare flexible carbon nanofibers by electrospinning, imidization and high-temperature carbonization:

[0035] (1) Electrospinning: Add 0.1mol p-phenylenediamine and 0.1mol pyromellitic dianhydride to 30mL N, M dimethylformamide solvent at a molar ratio of 1:1, and dissolve them at 0°C under a nitrogen atmosphere. The polycondensation reaction was carried out for 12 hours to obtain a polyamic acid solution. The obtained polyamic acid solution is subjected to electrospinning, and the adjustment process parameters are: electrostatic field voltage 20kV, spinning speed 0.1mmmin -4 , the receiving distance is 20em, and the polyamic acid nanofiber membrane is prepared.

[0036] (2) Imidization: The polyamic acid nanofiber membrane was imidized under nitrogen environment, the imidization temperature was 300°C, and the heating rate was 2°C min -1 , th...

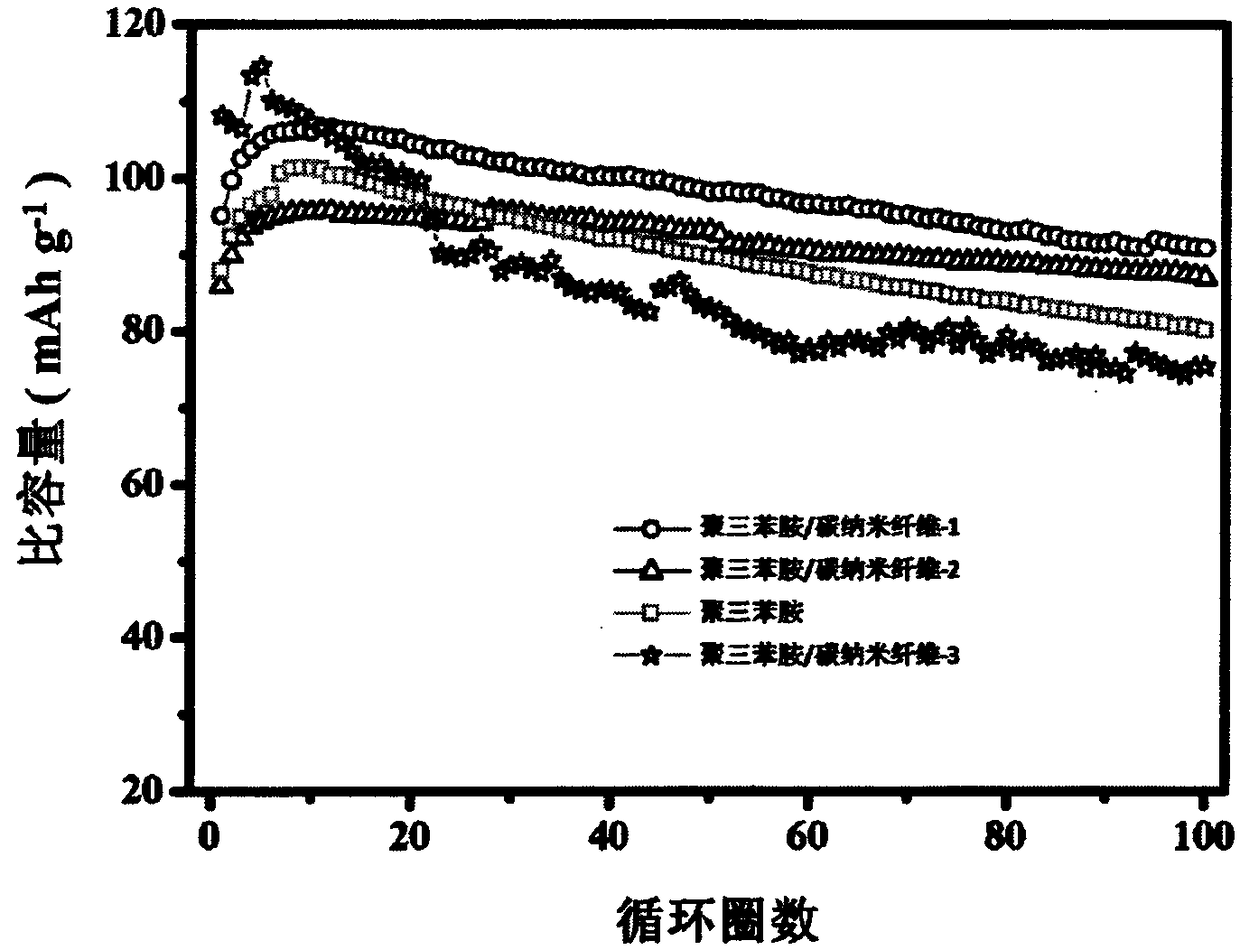

Embodiment 2

[0041] This example is similar to Example 1, except that the amount of triphenylamine is changed to 8 mmol, and the finally obtained composite material is recorded as polytriphenylamine / carbon nanofiber-2.

Embodiment 3

[0043] This example is similar to Example 1, except that the molar ratio of ferric chloride to triphenylamine is 2:1, and the finally obtained composite material is denoted as polytriphenylamine / carbon nanofiber-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com