Production process of high-nitrogen sulfur-based compound fertilizer

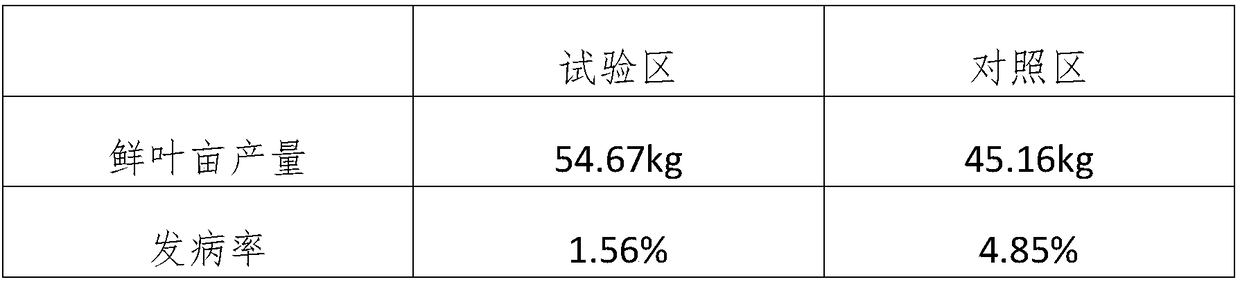

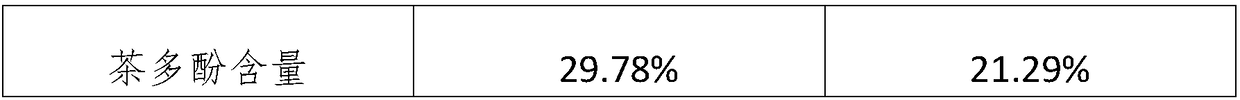

A production process, the technology of nitrogen, phosphorus and potassium compound fertilizer, which is applied in the field of production process of high nitrogen and sulfur-based compound fertilizer, can solve the problem of inability to achieve simultaneous and uniform release of nitrogen, phosphorus and potassium, unreasonable fertilizer use angle, and nitrogen utilization by crops. Low-level problems, to achieve the effect of promoting photosynthesis, improving yield and quality, and anti-caking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A production technology of high nitrogen-sulfur-based compound fertilizer, the implementation method is as follows:

[0021] The nitrogen-phosphorus-potassium compound fertilizer slurry is transported to the top of the high tower by a slurry pump, and falls down in an atomized state through the nozzle, and conducts countercurrent heat exchange with the 120 ℃ low-temperature hot air introduced at the bottom of the high tower, and the exhaust gas is emptied after dust collection. The hot powder NPK compound fertilizer is metered into the disc pelletizer and mixed with the metered sulfur sol to obtain the compound base material. After the temperature drops to 5°C, the ammonium bicarbonate powder is added. In the dryer, the co-current heat exchange is carried out with the low-temperature air. The fertilizer particles are dried and polished at a low temperature of 20°C in the dryer. The dried materials are sieved and packaged into products, and the sieved fine powder is retur...

Embodiment 2

[0023] A production technology of high nitrogen-sulfur-based compound fertilizer, the implementation method is as follows:

[0024] The nitrogen-phosphorus-potassium compound fertilizer slurry is transported to the top of the high tower by a slurry pump, and falls down in an atomized state through the nozzle, and conducts countercurrent heat exchange with the 120 ℃ low-temperature hot air introduced at the bottom of the high tower, and the exhaust gas is emptied after dust collection. The hot powder NPK compound fertilizer is metered into the disc pelletizer and mixed with the metered sulfur sol to obtain the compound base material. After the temperature drops to 8°C, the ammonium bicarbonate powder is added. In the dryer, the co-current heat exchange is carried out with the low-temperature air. The fertilizer particles are dried and polished at a low temperature of 25°C in the dryer. The dried materials are screened and packaged into products, and the screened fine powder is r...

Embodiment 3

[0026] A production technology of high nitrogen-sulfur-based compound fertilizer, the implementation method is as follows:

[0027] The nitrogen-phosphorus-potassium compound fertilizer slurry is transported to the top of the high tower by a slurry pump, and falls down in an atomized state through the nozzle, and conducts countercurrent heat exchange with the 120 ℃ low-temperature hot air introduced at the bottom of the high tower, and the exhaust gas is emptied after dust collection. The hot powder NPK compound fertilizer is metered into the disc pelletizer and mixed with the metered sulfur sol to obtain the compound base material. After the temperature drops to 10°C, ammonium bicarbonate powder is added. In the dryer, the co-current heat exchange is carried out with the low-temperature air. The fertilizer particles are dried and polished at a low temperature of 30°C in the dryer. The dried materials are sieved and packaged into products, and the sieved fine powder is returned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com