Compound wintercreeper soft capsule and preparation method thereof

A technology for soft capsules and compound recipes, applied in the field of compound Fufangteng soft capsules and their preparation, can solve the problems of difficulty in promoting the absorption of raw materials, inability to cover the odor of raw materials, easy access to air, oxidation, etc., and achieve the promotion of drug efficacy. , to ensure the comfort of taste and improve the effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation approach Embodiment 1

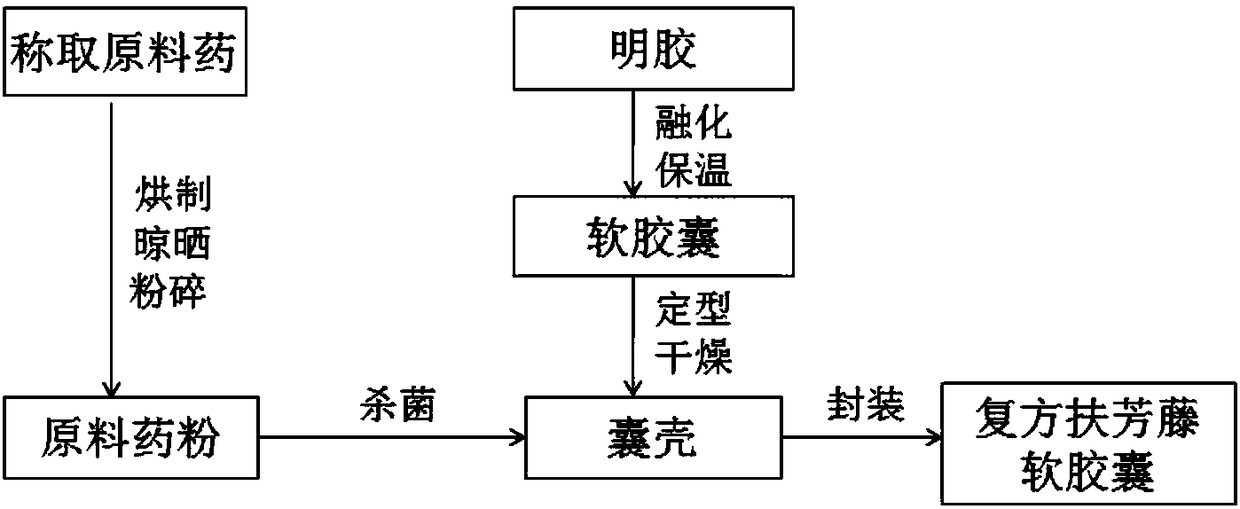

[0023] Preparation Process:

[0024] Step 1: melting and heat preservation of gelatin, the melting temperature is 70°C, and the heat preservation temperature is 60°C;

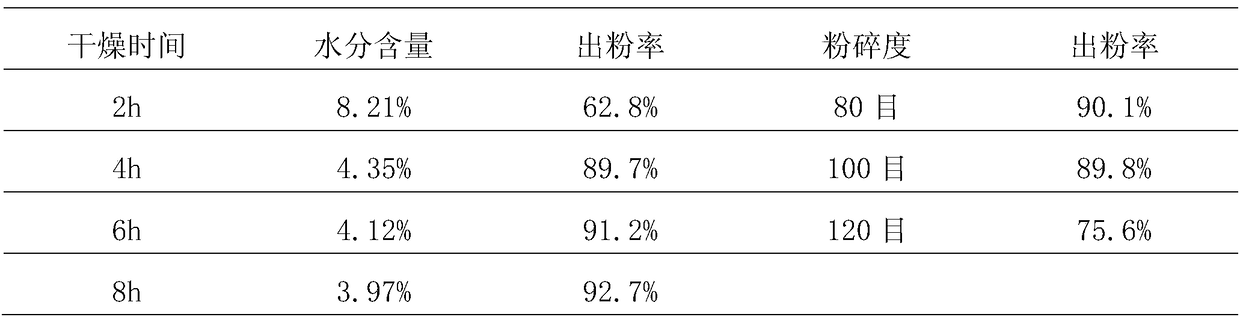

[0025] Step 2: Drying and shaping of the capsule shell: Use a drying roller cage machine to shape and dry the soft capsules to remove excess water from the pressed soft capsules, so as to maintain the appearance of the soft capsules and moderate disintegration, and the capsules after water removal The water content of the finished product is at the quality standard of 10%, the water removal temperature is 60°C, and the water removal time is 6 hours;

[0026] Step 3: Weigh the raw materials according to the formula, 130 parts by weight of fufangteng, 100 parts by weight of red ginseng and 30 parts by weight of astragalus, bake at 80°C for 5 hours, air-dry to room temperature, mix and pulverize for 30 minutes, and pass through a 100-mesh sieve , to obtain raw material drug powder;

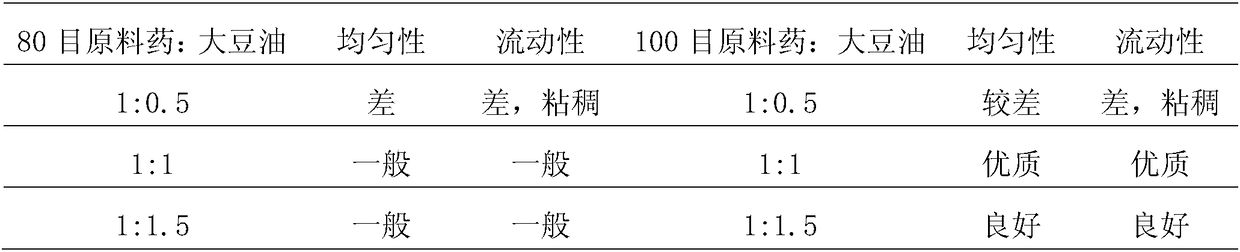

[0027] Step 4: After sterili...

preparation approach Embodiment 2

[0029] Preparation Process:

[0030] Step 1: melting and heat preservation of gelatin, the melting temperature is 70°C, and the heat preservation temperature is 60°C;

[0031] Step 2: Drying and shaping of the capsule shell: Use a drying roller cage machine to shape and dry the soft capsules to remove excess water from the pressed soft capsules, so as to maintain the appearance of the soft capsules and moderate disintegration, and the capsules after water removal The water content of the finished product is at the quality standard of 10%, the water removal temperature is 60°C, and the water removal time is 6 hours;

[0032] Step 3: Weigh the raw materials according to the formula, 120 parts by weight of fufangteng, 80 parts by weight of red ginseng and 20 parts by weight of astragalus, bake at 80°C for 5 hours, air-dry to room temperature, mix and pulverize for 30 minutes, and pass through a 100-mesh sieve , to obtain raw material drug powder;

[0033] Step 4: After steriliz...

preparation approach Embodiment 3

[0035] Preparation Process:

[0036] Step 1: melting and heat preservation of gelatin, the melting temperature is 70°C, and the heat preservation temperature is 60°C;

[0037] Step 2: Drying and shaping of the capsule shell: Use a drying roller cage machine to shape and dry the soft capsules to remove excess water from the pressed soft capsules, so as to maintain the appearance of the soft capsules and moderate disintegration, and the capsules after water removal The water content of the finished product is at the quality standard of 10%, the water removal temperature is 60°C, and the water removal time is 6 hours;

[0038] Step 3: Weigh the raw materials according to the formula, 150 parts by weight of fufangteng, 120 parts by weight of red ginseng and 50 parts by weight of astragalus, bake at 80°C for 5 hours, air-dry to room temperature, mix and pulverize for 30 minutes, and pass through a 100-mesh sieve , to obtain raw material drug powder;

[0039] Step 4: After sterili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com