Granular medium-trace nutrient element fertilizer and production method thereof

A technology of nutrient elements and micronutrients, applied in the direction of inorganic fertilizers, ammonium salt fertilizers, calcium fertilizers, etc., can solve the problems of soil acidification, reduction of the utilization rate of macronutrient fertilizers, and lack of supplementation of micronutrient elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

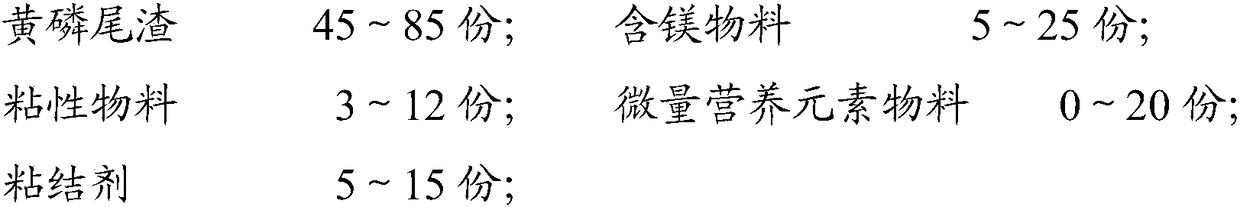

Method used

Image

Examples

Embodiment 1

[0093] Embodiment 1: the production of micronutrient element fertilizer in granular form of the present invention

[0094] The implementation steps of this embodiment are as follows:

[0095] A. Raw material mixing

[0096] 45 parts by weight containing 47% CaO, 39% SiO by weight 2 Yellow phosphorus tailings, 25 parts by weight of magnesite magnesium-containing raw materials containing 45% MgO by weight, 3 parts by weight of bentonite viscous materials and 0 parts by weight of micronutrient raw materials are put into a mixer and mixed uniformly to obtain a raw material mixture;

[0097] B. Preparation of binder solution

[0098] Polyacrylamide is formulated into a polyacrylamide solution with a concentration of 1.0% by weight with water;

[0099] C. Granulation

[0100]First put a part of the raw material mixture obtained in step A into the granulation pan, take out the binder solution prepared in step B according to 7 parts by weight of binder, and put a part of it under...

Embodiment 2

[0107] Embodiment 2: the production of micronutrient element fertilizer in granular form of the present invention

[0108] The implementation steps of this embodiment are as follows:

[0109] A. Raw material mixing

[0110] 54 parts by weight containing 47% CaO, 39% SiO by weight 2 yellow phosphorus tailings, 18 parts by weight of light-burned magnesium-containing magnesium raw materials containing 72% MgO by weight, 5 parts by weight of attapulgite sticky material and 4 parts by weight of zinc sulfate heptahydrate, manganese sulfate tetrahydrate, and copper sulfate pentahydrate , Borax and ammonium molybdate (their weight ratio 1:1:1:1:0.1) micronutrient raw materials are put into the mixer and mixed uniformly to obtain a raw material mixture;

[0111] B. Preparation of binder solution

[0112] Polyvinyl alcohol is prepared into a concentration of 0.1% polyvinyl alcohol solution by weight with water;

[0113] C. Granulation

[0114] First put a part of the raw material m...

Embodiment 3

[0121] Embodiment 3: the production of micronutrient element fertilizer in granular form of the present invention

[0122] The implementation steps of this embodiment are as follows:

[0123] A. Raw material mixing

[0124] 85 parts by weight containing 47% CaO, 39% SiO by weight 2 yellow phosphorus tailings, 9 parts by weight of calcined white stone magnesium-containing raw material containing 38% MgO by weight, 7 parts by weight of activated clay viscous material and 20 parts by weight of zinc oxide, manganese oxide, copper sulfate pentahydrate, boric acid, sodium molybdate 1. Ferric ammonium polyphosphate (weight ratio 1:1:3:1:0.5:4) micronutrient raw materials are put into the mixer and mixed evenly to obtain a raw material mixture;

[0125] B. Preparation of binder solution

[0126] The modified starch preparation concentration is a modified starch solution of 5% by weight with water;

[0127] C. Granulation

[0128] First put a part of the raw material mixture obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com