Copolymerized liquid fluorosilicone rubber based on isopropanol extracting method

A technology of fluorosilicone raw rubber and isopropanol, applied in the field of polymer chemistry, can solve problems such as rubber decomposition and energy loss, and achieve the effects of reducing shrinkage rate, avoiding energy loss and improving thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In a nitrogen-protected container, add 10g tetramethylammonium hydroxide pentahydrate, 122g octamethylcyclotetrasiloxane, 120ml toluene, react at 85°C for 1 hour, stop heating and cool to room temperature, under reduced pressure, The toluene was slowly steamed at 70°C, and the toluene was continuously replenished during the distillation process. After 6 hours, the distillation was stopped and cooled to room temperature. The α,ω-diamine(tetramethylammonium)methylsiloxane (TMAc) initiator was obtained.

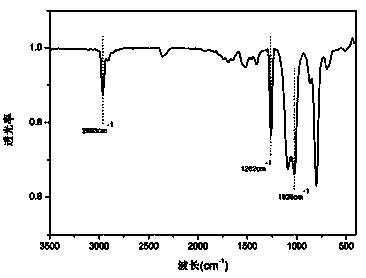

[0036] The proton nuclear magnetic resonance spectrum of TMAc was measured with a Bruker Advance 510 nuclear magnetic resonance instrument (300 MHz), and the deuterated CDCl 3 as the solvent, with TMS (tetramethylsilane) as the internal standard, the test results are shown in figure 1 . Depend on figure 1 It can be seen that TMAc has only one proton magnetic peak, and the peak position is at 2.38ppm. It was proved that the synthesized TMAc was consistent with the expe...

Embodiment 2

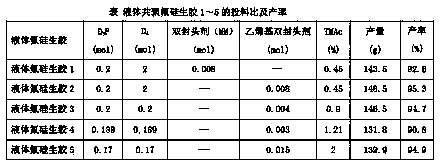

[0044] Polymerization was carried out by changing the feed ratio, and the synthesis process was the same as in Example 1 to obtain homogeneous and transparent liquid fluorosilicone raw rubber 6-10. Feed ratio and yield see Figure 13 .

Embodiment 3

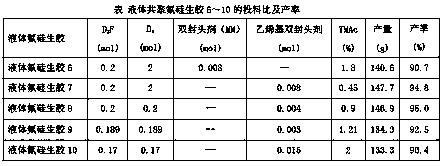

[0046] Polymerization was carried out by changing the feed ratio, and the synthesis process was the same as in Example 1 to obtain liquid fluorosilicone raw rubber 15-21. Feed ratio and yield see Figure 14 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com