Polyester fiber and preparation method thereof

A technology of polyester fiber and poly pairs, which is applied in the field of polyester fiber and its preparation, can solve the problems of antibacterial and unsatisfactory mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

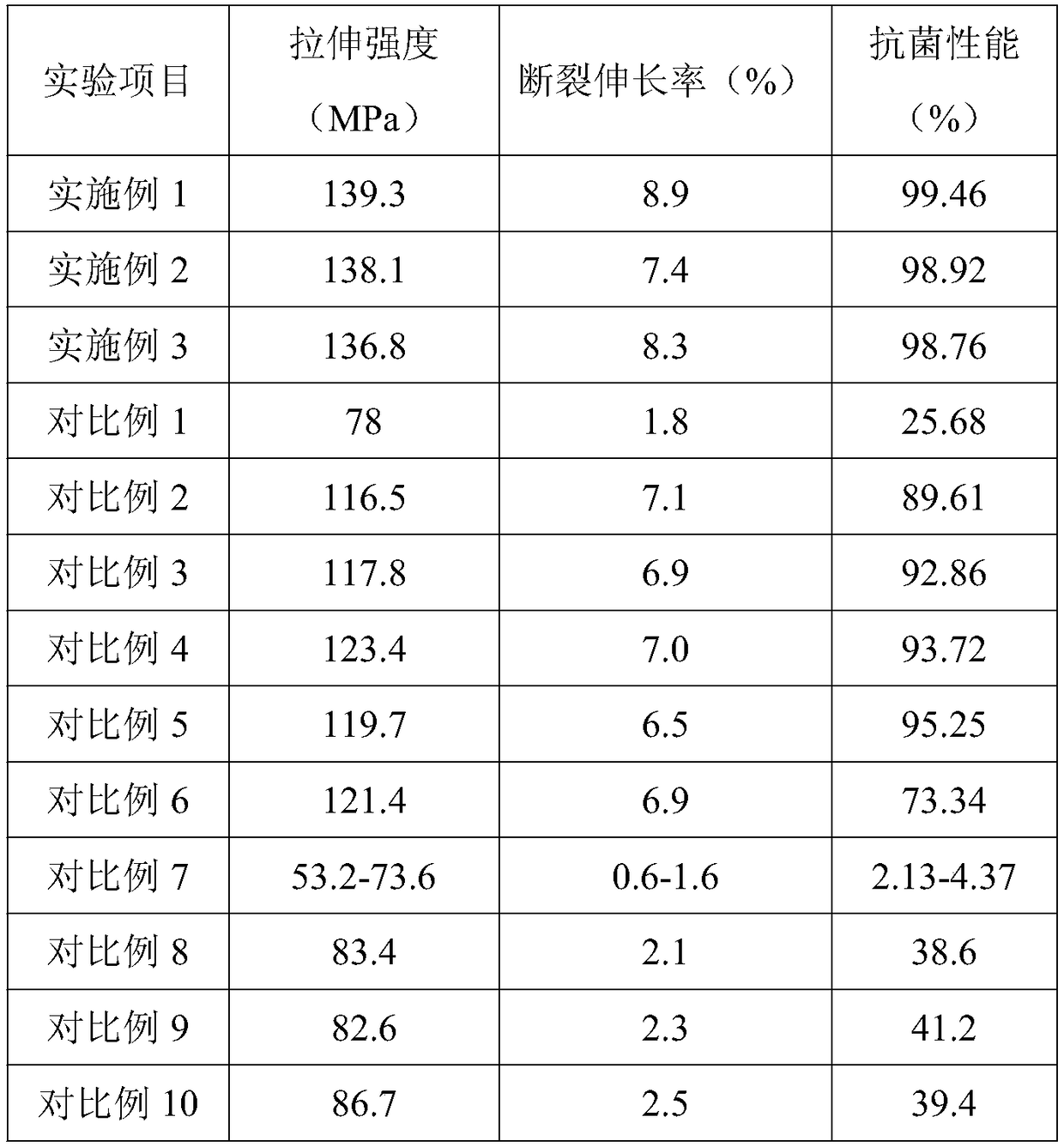

Examples

preparation example Construction

[0025] The preparation method of described polyester fiber, comprises the following steps:

[0026] S1: Mix polyoxyethylene, ethoxylated glycerin, nano-silica, carbon nanotubes, chitosan, antibacterial modification additives, mechanical property enhancement additives and silane coupling agent KH-570, and heat up to 80-90°C, keep warm for 20-40min, then add polyethylene terephthalate and mix evenly, stir at 1500-2500r / min for 20-40min to form a polyester composition;

[0027] S2: Drying the polyester composition at 70-80° C. for 20-30 minutes and then melt-spinning it into polyester fibers.

Embodiment 1

[0029] A polyester fiber, in parts by weight, comprising the following raw materials: 74 parts of polyethylene terephthalate, 13 parts of polyoxyethylene, 11.5 parts of nano silicon dioxide, 3.2 parts of rare earth coupling agent, ethoxylated 2.8 parts of glycerin, 5.8 parts of carbon nanotubes, 4.3 parts of chitosan, 25.8 parts of antibacterial modification additives, 21.6 parts of mechanical property enhancement additives, and 2.6 parts of silane coupling agent KH-570.

[0030] The antibacterial modification auxiliary agent is prepared according to the following process: 12.3 parts by weight of 3,4-dihydroxybenzaldehyde, 5.6 parts of diphenylmethane diisocyanate, 11.4 parts of distilled water, 7.2 parts of dibutyltin dilaurate, 4.3 parts Mix 1 part of acetic acid and 5.7 parts of methanol evenly, let it stand at room temperature for 4.2h, then add 3.9 parts of sodium borohydride and mix evenly, stir at 746r / min for 36min, the precipitate obtained after suction filtration is d...

Embodiment 2

[0036] A polyester fiber, in parts by weight, comprising the following raw materials: 60 parts of polyethylene terephthalate, 20 parts of polyoxyethylene, 10 parts of nano silicon dioxide, 4 parts of rare earth coupling agent, ethoxylated 2 parts of glycerin, 9 parts of carbon nanotubes, 3 parts of chitosan, 26 parts of antibacterial modification additives, 18 parts of mechanical property enhancement additives, and 3 parts of silane coupling agent KH-5703.

[0037] The antibacterial modification auxiliary agent is prepared according to the following process: 5 parts by weight of 3,4-dihydroxybenzaldehyde, 8 parts of diphenylmethane diisocyanate, 8 parts of distilled water, 8 parts of dibutyltin dilaurate, 2 parts by weight Mix 1 part of acetic acid and 9 parts of methanol evenly, let it stand at room temperature for 3 hours, then add 5 parts of sodium borohydride and mix evenly, stir at 650r / min for 40 minutes, and the precipitate obtained after suction filtration is dialyzed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com