Thermodynamic method and system for cement kiln to realize cooperative treatment of domestic garbage

A technology for domestic waste and co-processing, applied in cement production, combustion methods, waste heat treatment, etc., can solve the problems of high transportation cost, heat loss, energy waste, etc., and achieve economic benefits, increase power generation, and improve economic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

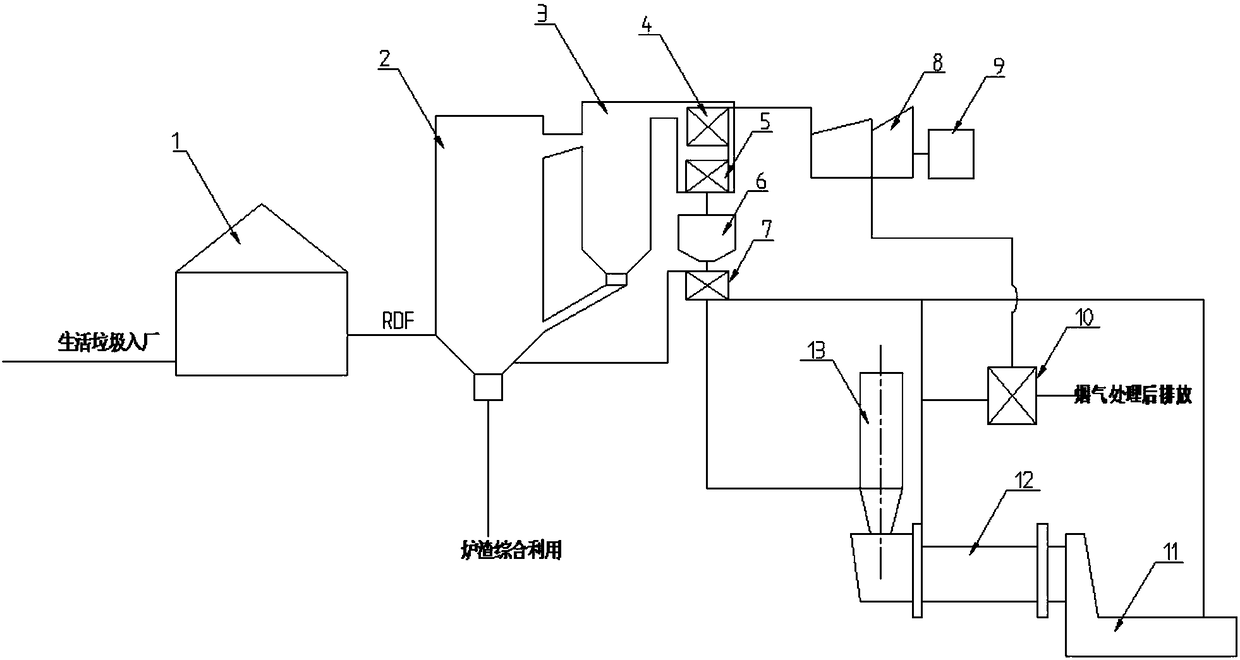

[0039] Such as figure 1 As shown, a thermal system for coordinating domestic waste in a cement kiln according to the present invention includes a waste incineration system, a power generation system, a cement production system and other auxiliary systems. The waste incineration system includes sequentially connected RDF production plants 1, fluidized bed incinerator 2, cyclone separator 3, superheater 4 and economizer 5, the power generation system includes an intake steam turbine 8 and a generator 9, the superheater is connected with the intake steam turbine and generator in turn, and other auxiliary systems include The denitrification device connected to the fluidized bed incinerator, the air preheater 7 connected to the cement calcining rotary kiln, and the waste heat boiler 10 for collecting the waste heat of the cement rotary kiln. The cement production system includes a cement decomposition furnace 13, a cement calcining rotary kiln 12 and a cement cooking The material c...

Embodiment 2

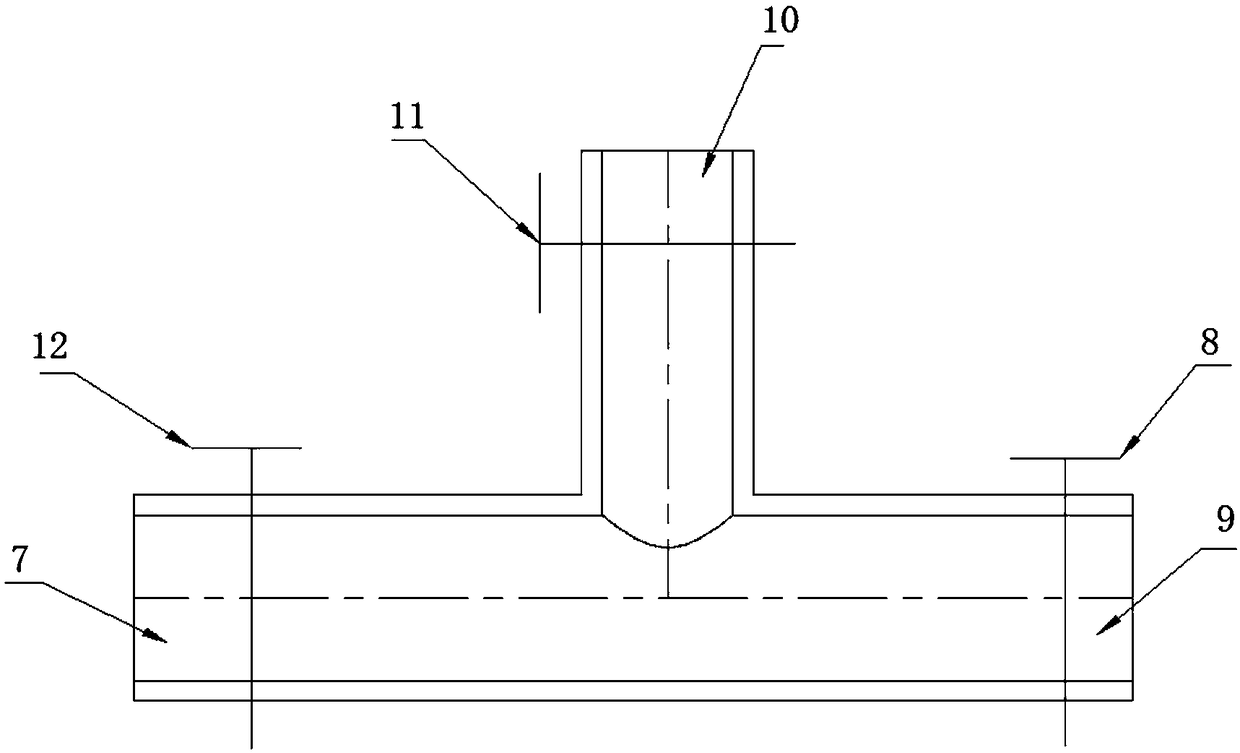

[0041] Such as image 3 As shown, the air supply pipe of the air preheater is a three-prong pipe structure, which are the flue gas inlet pipe of the cement calcining rotary kiln, the cooling air inlet pipe and the mixing pipe of the cement clinker cooling section. The flue gas inlet pipe of the cement calcining rotary kiln, the cooling air inlet pipe and the mixing pipe of the cement clinker cooling section are respectively provided with flue gas valves. All the other technical features are the same as in Embodiment 1.

[0042]The cooling air in the cement clinker cooling section is used as a high-temperature gas due to the high temperature of the cement clinker, and is used as the primary air of the fluidized bed incinerator, which has the effect of increasing the temperature of the furnace and improving the heat utilization efficiency.

[0043] All the other technical features are the same as in Embodiment 1.

Embodiment 3

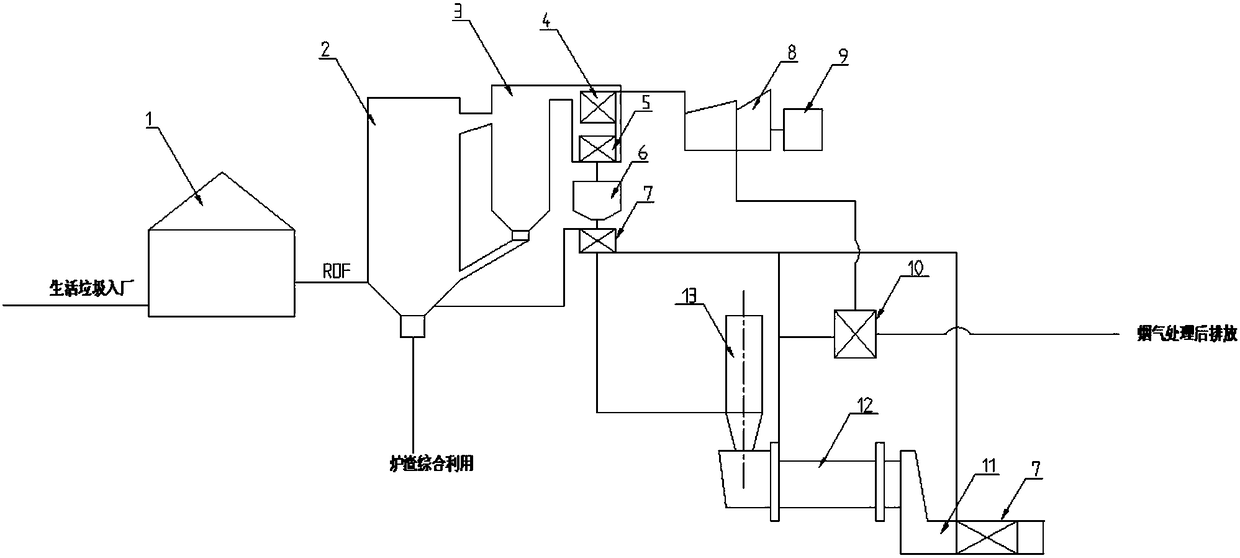

[0045] Such as figure 2 As shown, the air preheater is segmented, divided into air preheater section I14 and air preheater section II15, air preheater section I is connected to the tail flue of the fluidized bed incinerator, and the air preheater Section II is arranged in the cement clinker cooling section. The air supply pipe of the air preheater section I is a trident pipe structure, which are respectively the flue gas inlet pipe of the cement calcining rotary kiln, the heat exchange air inlet pipe and the mixing pipe of the air preheater section II, and the three pipes are respectively equipped with flue gas Air intake pipe control valve, heat exchange air intake pipe control valve and mixing pipe control valve. According to the fuel situation of the waste incinerator, the intake ratio and intake volume can be controlled in real time, so as to control the primary air volume and achieve the purpose of stable and efficient combustion.

[0046] All the other technical featu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com