A kind of preparation method of submicron lithium negative electrode material

A sub-micron, lithium negative electrode technology, applied in battery electrodes, lithium batteries, structural parts, etc., can solve problems such as large median particle size of metal lithium powder, inability to prepare lithium powder, and increased safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

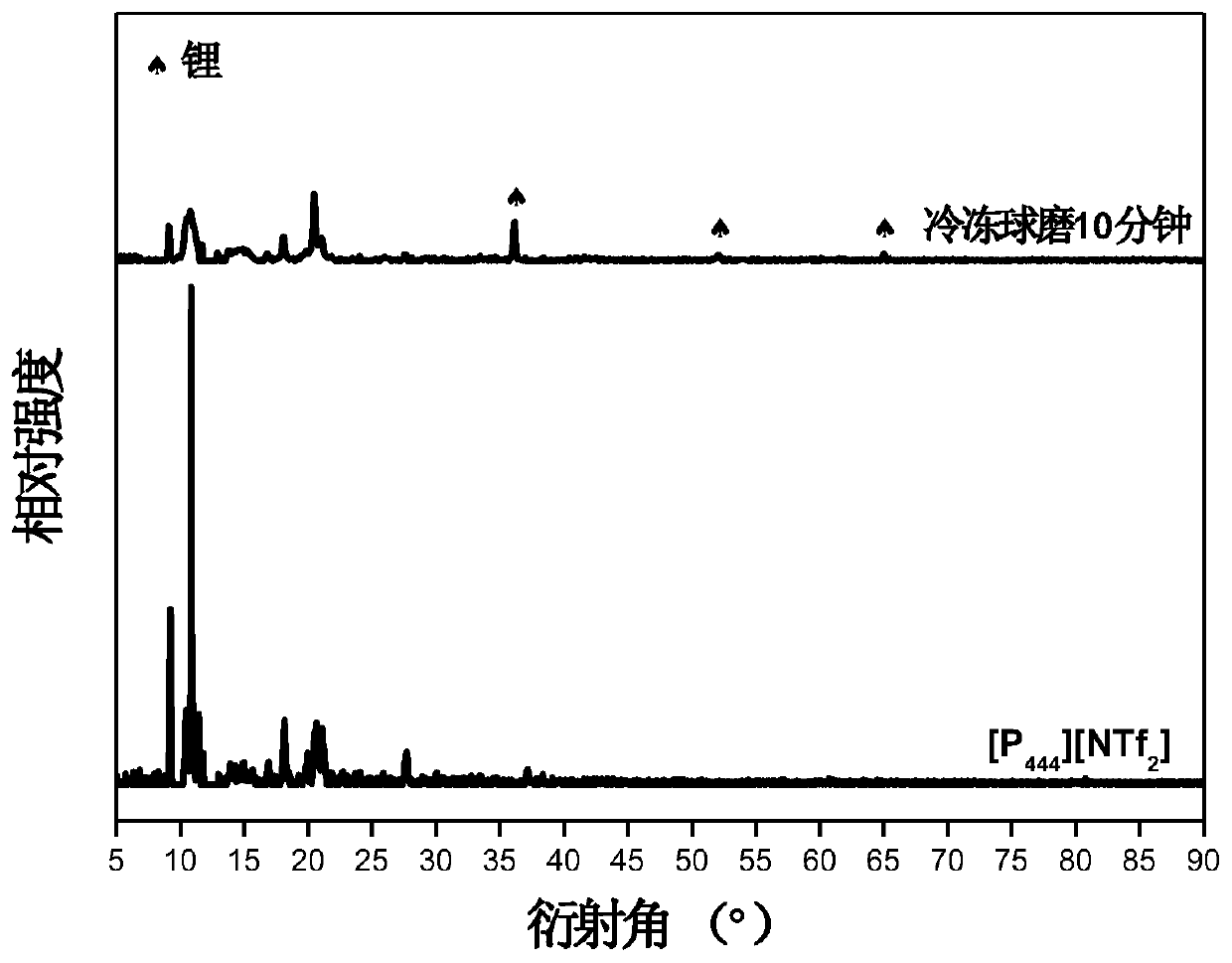

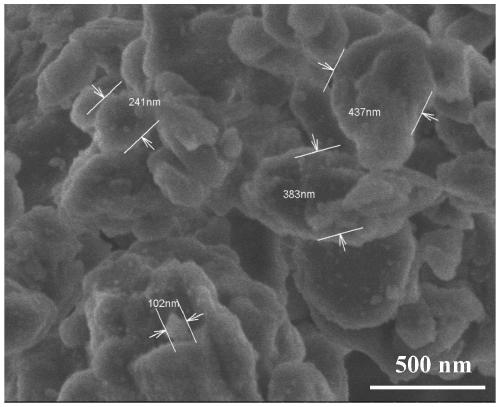

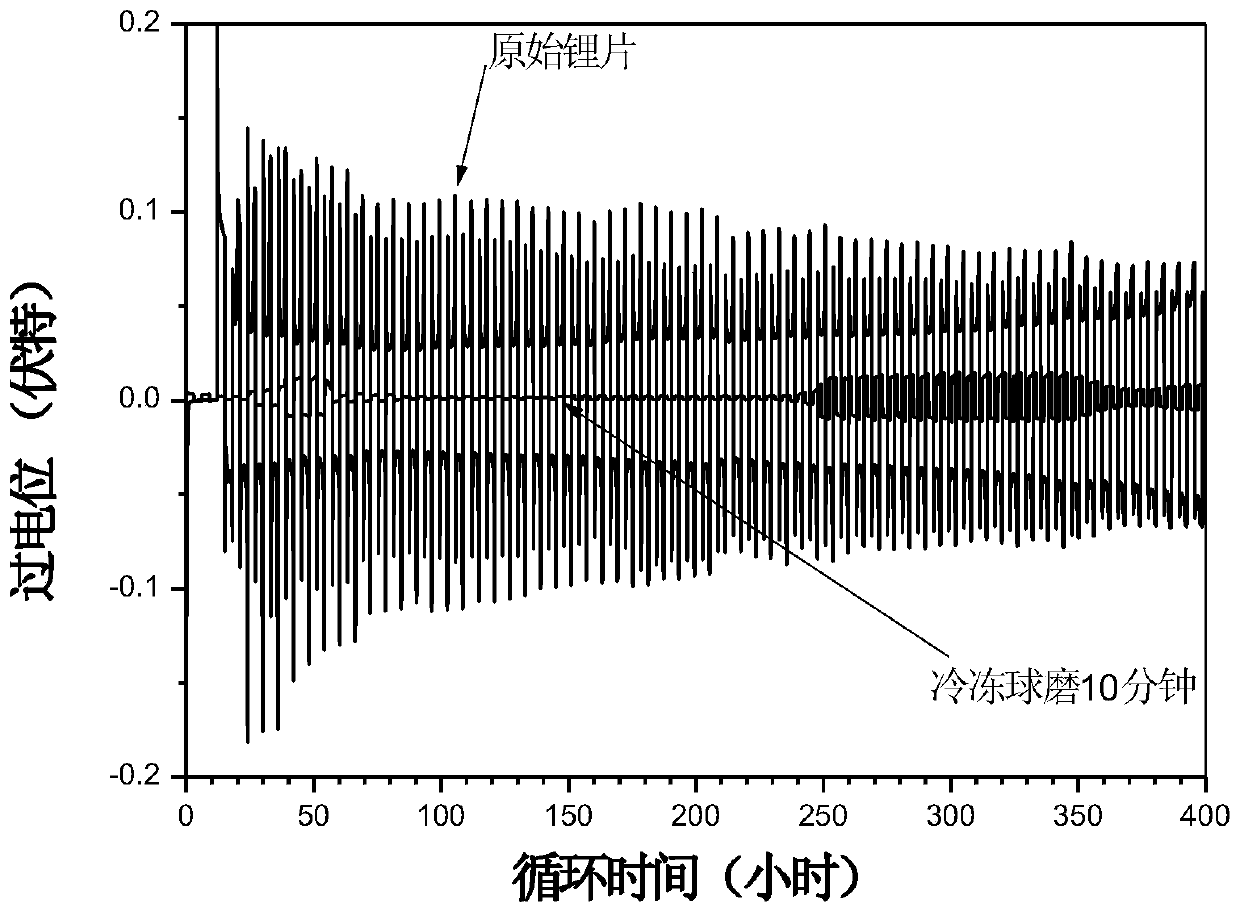

[0055] A method for preparing a submicron lithium negative electrode material, the specific contents are as follows:

[0056] (1) In a glove box of an argon atmosphere, 1 g of tetrabutylphosphine bis(trifluoromethanesulfonyl) imide salt ([P 444 ][NTf 2 ], melting point is 65°C) into a stainless steel ball mill jar, then heated to 150°C, and kept for 1 hour to remove moisture therein.

[0057] (2) [P] in the stainless steel ball mill jar 444 ][NTf 2 ] to 100°C, add 4 electrode-grade lithium sheets (mass about 0.32g) with a diameter of 15mm and a thickness of 0.7mm to form a [P 444 ][NTf 2 ] / lithium mixture.

[0058] (3) Place the stainless steel ball milling tank in the freezing medium liquid nitrogen to carry out the freezing ball milling; the mechanism of the freezing ball milling is: adopt the mode of vibratory ball milling, first pre-freeze for 15 minutes, and then carry out high-frequency ball milling, the frequency is 25Hz, and the time is 5 Minutes; then change to ...

Embodiment 2

[0084] (1) In dry air, mix 200mg of N-butyl-N-methylpyrrolidine bis(fluoromethanesulfonyl)imide salt ([C 4 mPyr + ][FSI - ]) centrifuge tube, and then heated to 130 ° C, and kept for 0.5 hours to remove the water.

[0085] (2) Then [C 3 mPyr + ][FSI - ] Cool down to 120° C., add 250 mg of lithium particles with a particle size of about 3 to 5 mm. After cooling to room temperature, the [C 3 mPyr + ][FSI - ] / lithium particle mixture is put into the ball milling tank, and the planetary freezing ball mill is used for freezing ball milling.

[0086] (3) Put the stainless steel ball milling tank in the planetary freezing ball mill, and carry out the freezing ball milling in the medium liquid nitrogen; the mechanism of the freezing ball milling is: adopt the method of planetary ball milling, pre-freeze for 30 minutes first, and then perform high-speed ball milling, The rotating speed is 400rpm, and the time is 15 minutes; then change to low-speed ball milling for intermediat...

Embodiment 3

[0089] (1) In a glove box of an argon atmosphere, 50 mL of N-butyl-N-methylpiperidine bis(trifluoromethanesulfonyl)imide salt ([Pp 14 + ][TFSI - ]) was added to a stainless steel bottle with a lid, and then heated to 200°C and kept for 8 hours to remove moisture therein.

[0090] (2) Then [Pp 14 + ][TFSI - ] cool down to 150°C, add 100mg of electrode-grade lithium flakes with a diameter of 15mm and a thickness of 0.7mm, cool to room temperature, and [C 3 mPyr + ][FSI - ] / lithium particle mixture is put into the ball mill tank, and the horizontal frozen ball mill is used to carry out frozen ball milling.

[0091] (3) Place the stainless steel ball milling tank in the freezing medium liquid nitrogen for freezing ball milling; the mechanism of freezing ball milling is: adopt the mode of planetary ball milling, first pre-freeze for 30 minutes, and then carry out high-speed ball milling, the rotating speed is 500rpm, and the time is 20 Minutes; then change to low-speed ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com