Method for preparing potassium ion battery electrode potassium type birnessite

A technology of birnessite and battery materials, applied in battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

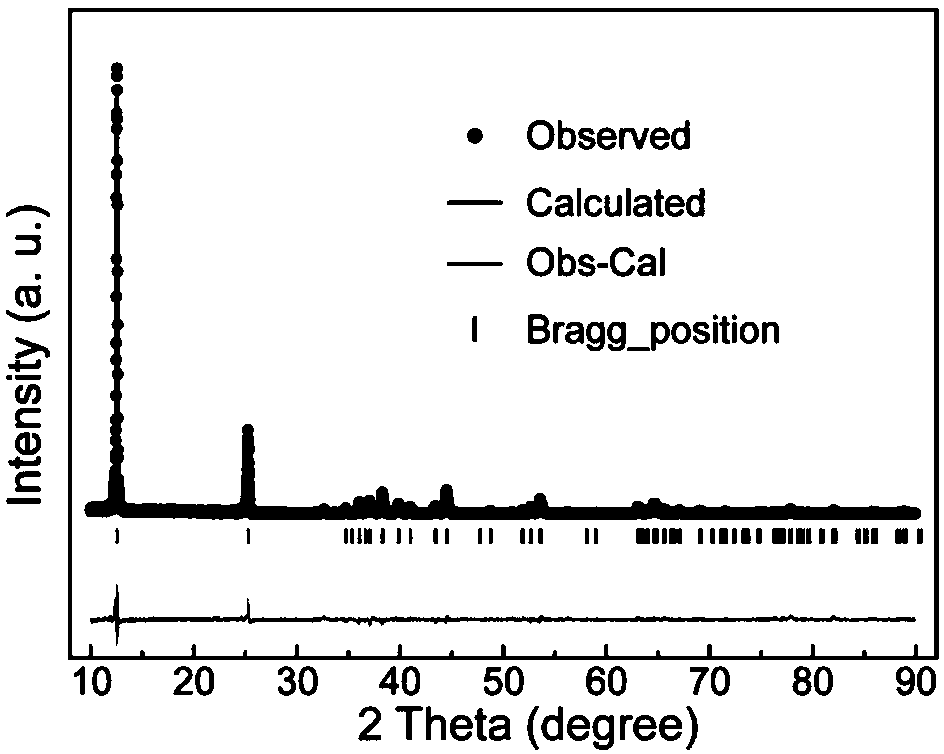

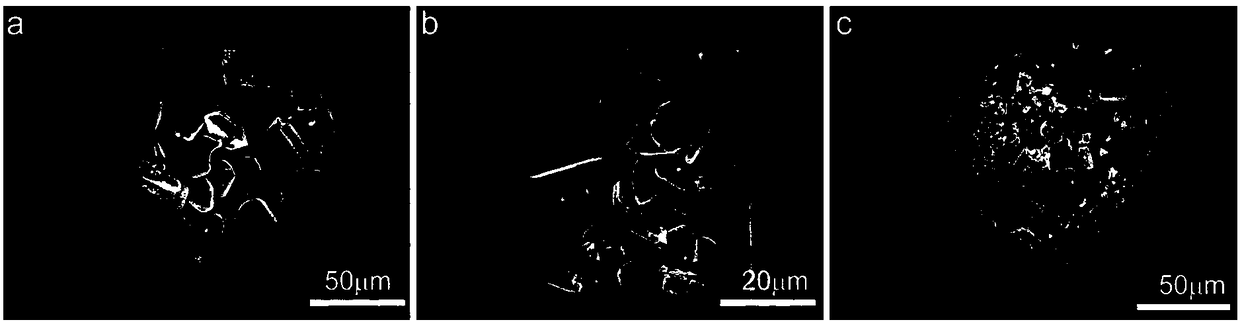

[0029] Weigh 4.83g K 2 CO 3 and 8.70g MnO 2 , milled with a ball mill for 15 hours, mixed uniformly to obtain a powder precursor, and then in a high-temperature furnace, under an air atmosphere, at 5°C min -1 The heating rate was increased to the preset temperature of 850°C, kept for 15 hours, cooled to room temperature naturally, the obtained product was washed with deionized water, and dried at 70°C to obtain the potassium birnessite material. X-ray diffraction (XRD) refinement (Fullprof) figure is shown in figure 1 , SEM photographs are shown in image 3 a, The sample exhibits a lamellar morphology, with a particle size of about 30 μm, a sheet thickness of about 15 μm, and a potassium stoichiometric ratio of 0.21. Potassium-type birnessite electrode material in 0.8mol L -1 LiPF 6 (Solvent: propylene carbonate) as the electrolyte, at 80mA·g -1 After 50 cycles at a certain current density, the mass specific capacity remained at 53mAh g -1 , The capacity retention rate...

Embodiment 2

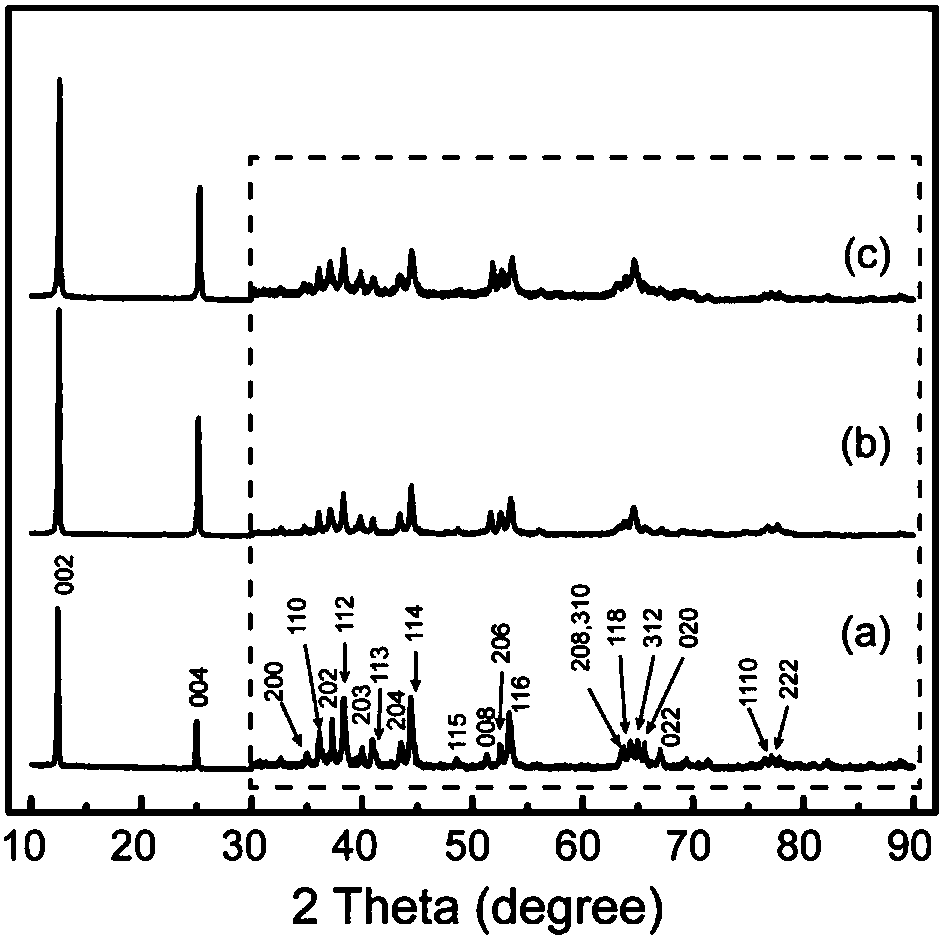

[0031] The operation is the same as in Example 1, and the potassium-type birnessite material is prepared, and 4.50g of potassium-type birnessite is weighed and transferred to 3mol L -1 Heat and reflux at 130°C in potassium hydroxide solution for 5 hours, and the obtained product is filtered and washed repeatedly with deionized water until it becomes neutral, and the product filter cake is moved into a drying oven at 70°C for 12 hours to obtain a high-potassium sodium water solution based on aqueous solution exchange. manganese ore material. XRD pattern shown in figure 2 , SEM photographs are shown in image 3 b, The sample presents a lamellar morphology, with a particle size of ~20 μm, a sheet thickness of ~15 μm, and a potassium stoichiometric ratio of 0.31. The galvanostatic charge-discharge curves of the high-potassium birnessite electrode material exchanged by aqueous solution at different current densities are shown in Figure 4 , with 0.8mol L -1 LiPF 6 (Solvent: p...

Embodiment 3

[0033] The operation was the same as that in Example 1, and the potassium-type birnessite material was prepared. Weighed 4.12g of potassium-type birnessite and mixed with 11.20g of potassium hydroxide solid, transferred to a high-temperature furnace for high-temperature sintering at 800°C for 15 hours, and naturally cooled to room temperature. The obtained product After repeated suction filtration and washing with deionized water until neutral, the product filter cake was moved into a drying oven at 70°C for 12 hours to obtain a high-potassium birnessite material based on high-temperature exchange. XRD pattern shown in figure 2 , SEM photographs are shown in image 3 c, Part of the sample retains a lamellar morphology, while there are a large number of finely divided particles, and the stoichiometric ratio of potassium reaches 0.28. High-potassium birnessite electrode material exchanged at high temperature in 1mol L - 1 LiPF 6 (Solvent: propylene carbonate) as the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com