Coal asphalt porous polymer prepared through heteropolyacid catalysis as well as preparation method and application thereof

A technology for the preparation of porous polymers and catalysis, which is applied in chemical instruments and methods, building structures, and other chemical processes. It can solve the problems of few high-molecular porous polymers, limit the development of porous materials, and long activation time. The effect of improving process production efficiency, friendly production equipment, and reducing process technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

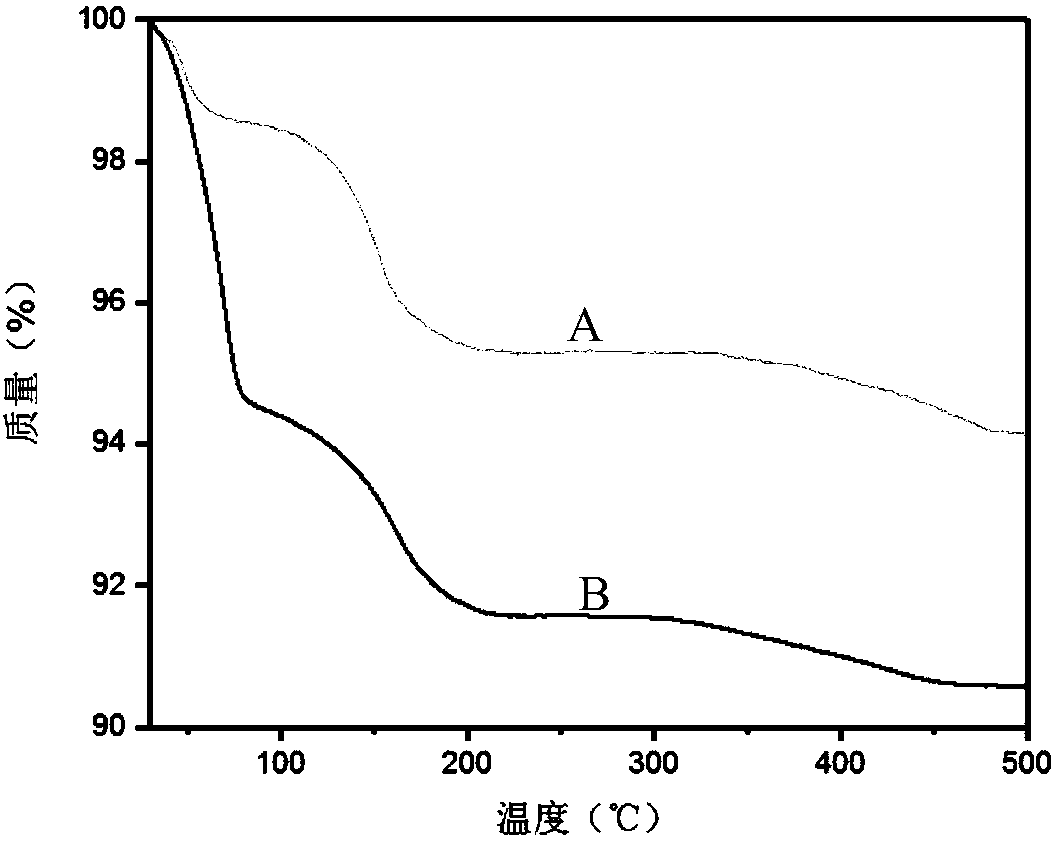

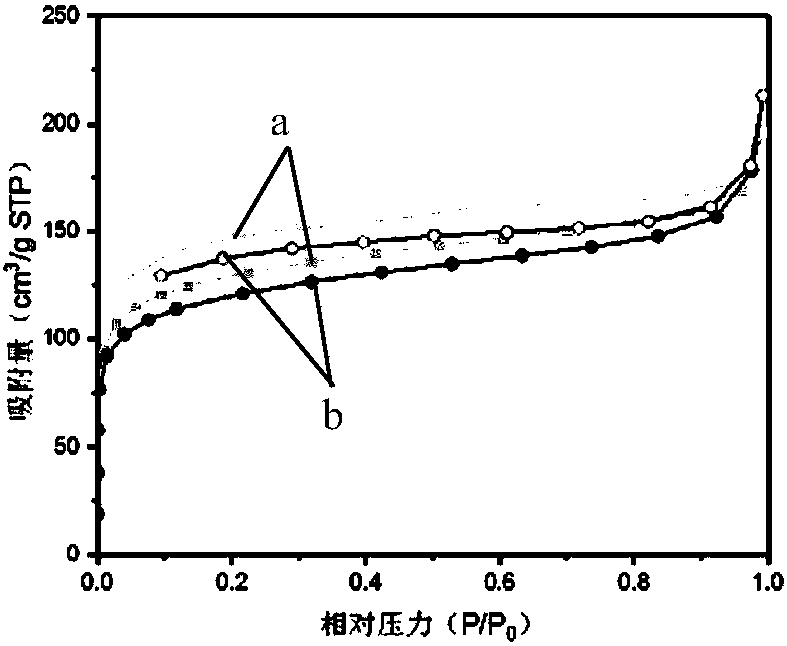

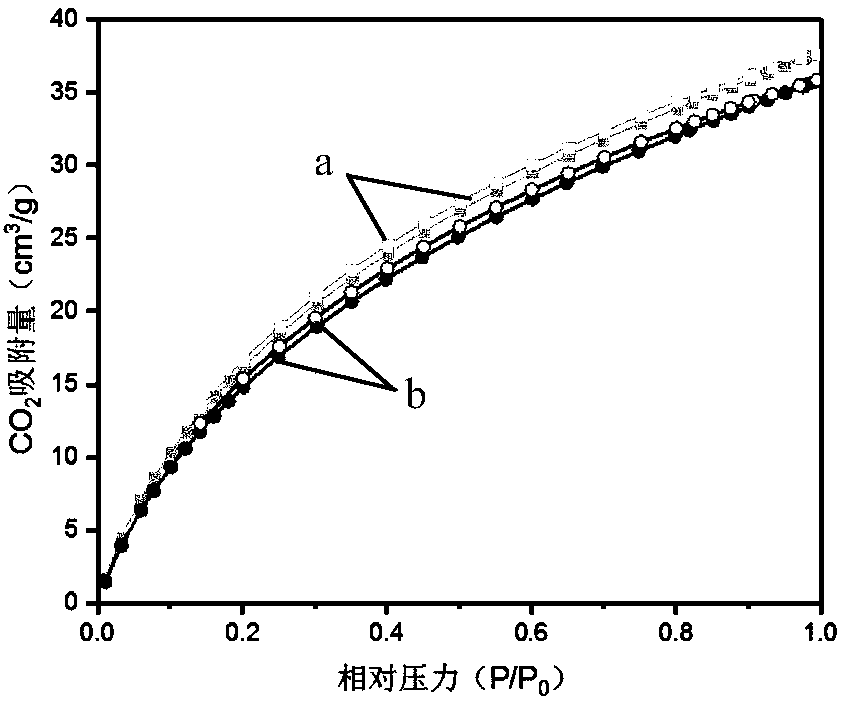

[0032] The preparation specific surface area is 489m 2 / g, the pore volume is 0.182cm 3 / g hypercrosslinked asphalt porous polymer.

[0033] The present embodiment adopts following formula:

[0034] Coal tar pitch: 100g

[0035] Dimethoxymethane: 300g

[0036] Phosphotungstic acid: 947g

[0037] 1,2-dichloroethane: 3000ml

[0038] Prepare asphalt porous polymer with above-mentioned formula composition according to following method:

[0039] 1. First add the weighed coal tar pitch into 1,2-dichloroethane. After it is completely dissolved, add dimethoxymethane, stir and mix, add heat-treated phosphotungstic acid, and mix well.

[0040] 2. The mixed composition was heated to 80° C. under nitrogen atmosphere, and cross-linked for 18 hours.

[0041] 3. Wash the cross-linked mixture in step 2 three times with methanol, collect the cleaning filtrate, then use the filtrate to extract the product for 12 hours, and then use 1,2-dichloroethane to extract the product for 12 hours; ...

Embodiment 2

[0044] The preparation specific surface area is 417m 2 / g, the pore volume is 0.221cm 3 / g hypercrosslinked asphalt porous polymer.

[0045] The present embodiment adopts following formula:

[0046] Coal tar pitch: 100g

[0047] Dimethoxymethane: 300g

[0048] Silicotungstic acid: 947g

[0049] 1,2-dichloroethane: 3000ml

[0050] Prepare asphalt porous polymer with above-mentioned formula composition according to following method:

[0051] 1. Dissolve the weighed coal tar pitch in 1,2-dichloroethane. After the dissolution is complete, add dimethoxymethane, stir and mix, add heat-treated silicotungstic acid, and mix well.

[0052] 2. The mixed composition was heated to 80° C. under a nitrogen atmosphere, and crosslinked for 18 hours.

[0053] 3. Wash the cross-linked mixture in step 2 three times with methanol, collect the cleaning filtrate, then use the filtrate to extract the product for 12 hours, and then use 1,2-dichloroethane to extract the product for 12 hours; 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com