Porous aluminum macroscopic body and manufacturing system and method thereof

A manufacturing system, porous aluminum technology, applied in the manufacture of hybrid/electric double-layer capacitors, electrode carriers/current collectors, structural parts, etc., can solve the problem of inability to achieve simultaneous sputtering of large-area samples, and the rising cost of water removal from porous polyurethane films , the melting of porous polyurethane film, etc., to achieve the effect of low cost, high speed and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

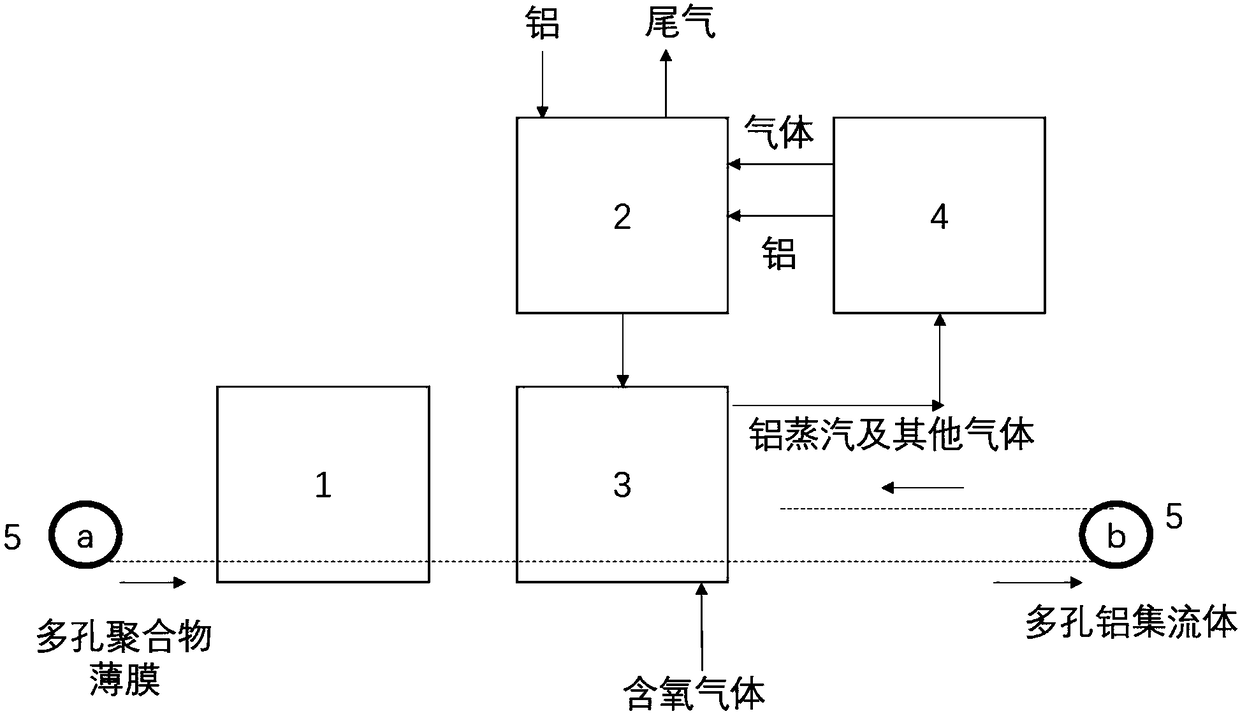

[0031] Such as figure 1 As shown, a porous polyurethane film with a thickness of 0.5mm, a width of 1mm, and an aspect ratio of 400000:1 is wound on the reel a of the subsystem 5, and is fed into the magnetron sputtering subsystem 1 at a speed of 1cm / min. In an inert gas (argon) environment with an absolute pressure of 5Pa and an absolute pressure of 5Pa, the surface power of the aluminum target is controlled to be 2W / cm 2 , onto one side of the porous polymer film was deposited successively by sputtering an aluminum layer with a thickness of 1 nm. Start the high-temperature aluminum vapor subsystem 2, in which the aluminum particles are always melted at 600°C in the melting pool, and become aluminum vapor (partial pressure 0.1%) in the presence of inert gas (nitrogen). The inert gas carries the aluminum vapor and moves to the low temperature aluminum deposition subsystem 3 . Set the temperature of the low-temperature aluminum deposition subsystem 3 to 200°C, and continuously...

Embodiment 2

[0034] Such as figure 1 As shown, a porous PVDF film with a thickness of 30 mm, a width of 500 mm, and an aspect ratio of 400:1 is wound on the reel a of the subsystem 5, and fed into the magnetron sputtering subsystem 1 at a speed of 20 cm / min. , In an inert gas (argon) environment with an absolute pressure of 0.5Pa, control the surface power of the aluminum target to 10W / cm 2, onto one side of the porous polymer film was continuously deposited by sputtering an aluminum layer with a thickness of 500 nm. Start the high-temperature aluminum vapor subsystem 2, in which the aluminum particles are always melted at 800°C in the melting pool, and become aluminum vapor (partial pressure 10%) in the presence of an inert gas (nitrogen). The inert gas carries the aluminum vapor and moves to the low temperature aluminum deposition subsystem 3 . Set the temperature of the low-temperature aluminum deposition subsystem 3 to 300°C, and continuously send the film from the magnetron sputteri...

Embodiment 3

[0037] Such as figure 1 As shown, a porous PTFE film with a thickness of 5 mm, a width of 50 mm, and an aspect ratio of 4000:1 is wound on the reel a of the subsystem 5, and is fed into the magnetron sputtering subsystem 1 at a speed of 10 cm / min. , In an inert gas (argon) environment with an absolute pressure of 2Pa, control the surface power of the aluminum target to 5W / cm 2 , onto one side of the porous polymer film was continuously deposited by sputtering an aluminum layer with a thickness of 100 nm. Start the high-temperature aluminum vapor subsystem 2, in which the aluminum particles are always melted at 700°C in the melting pool, and become aluminum vapor (partial pressure 3%) in the presence of an inert gas (argon). The inert gas carries the aluminum vapor and moves to the low temperature aluminum deposition subsystem 3 . Set the temperature of the low-temperature aluminum deposition subsystem 3 to 250°C, and continuously send the film from the magnetron sputtering s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com