Catalyst system for sulfur-containing hydrocarbon oxidative desulfurization and sulfur-containing hydrocarbon oxidative desulfurization method

A technology of oxidative desulfurization and catalyst, which is applied in the catalyst system of oxidative desulfurization of sulfur-containing hydrocarbons and the field of oxidative desulfurization of sulfur-containing hydrocarbons. The effect of desulfurization stability, simplification of tail gas treatment process, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

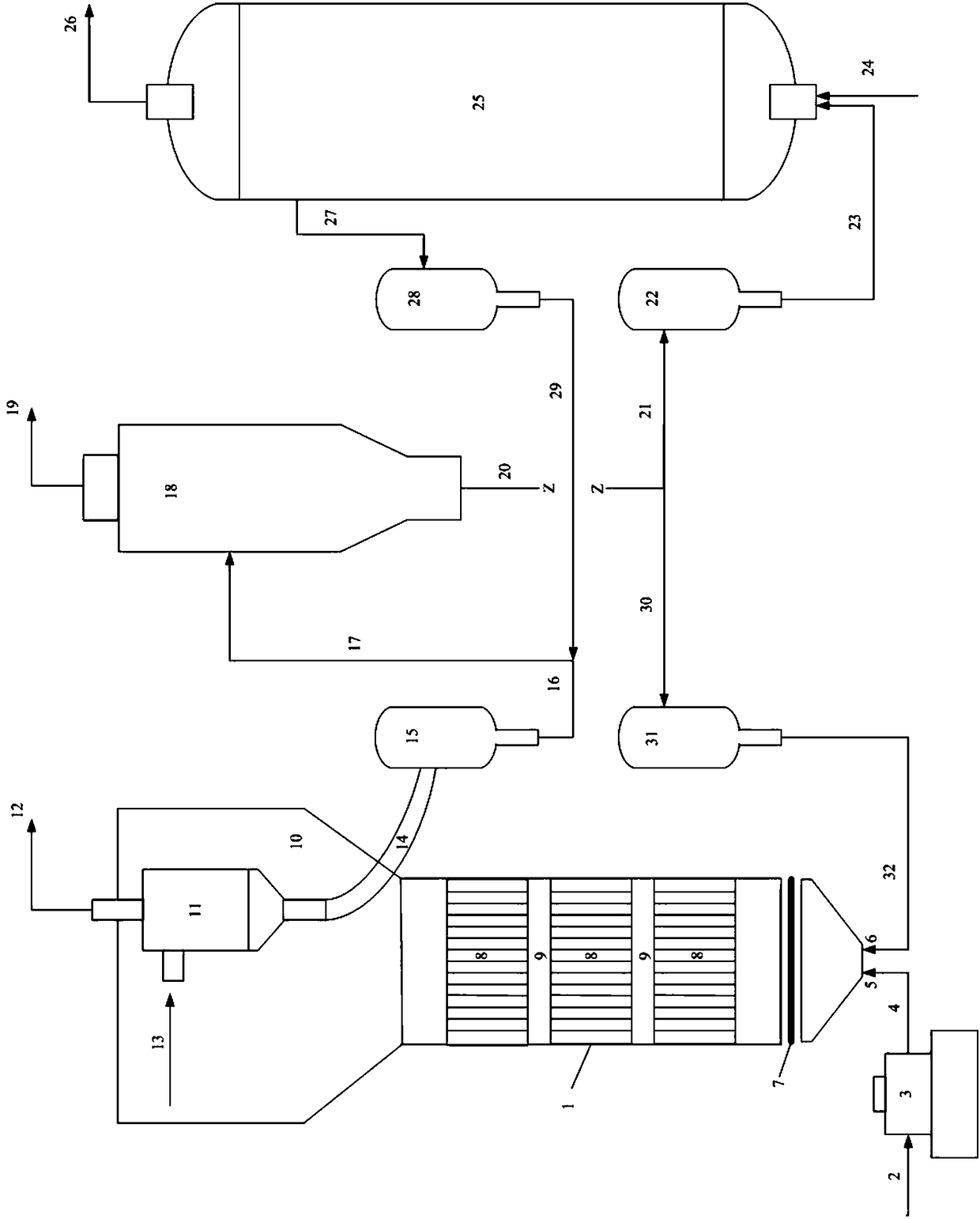

Method used

Image

Examples

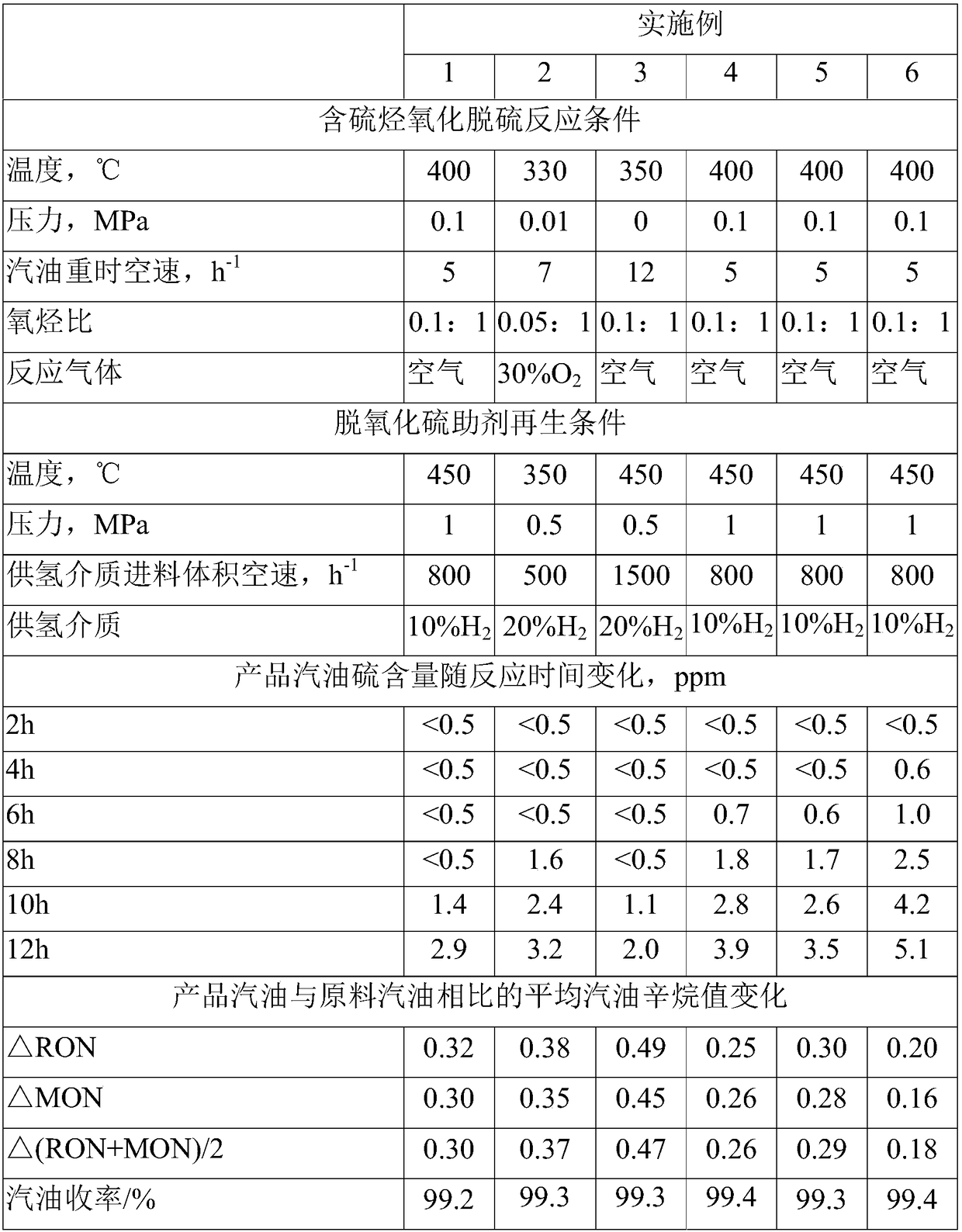

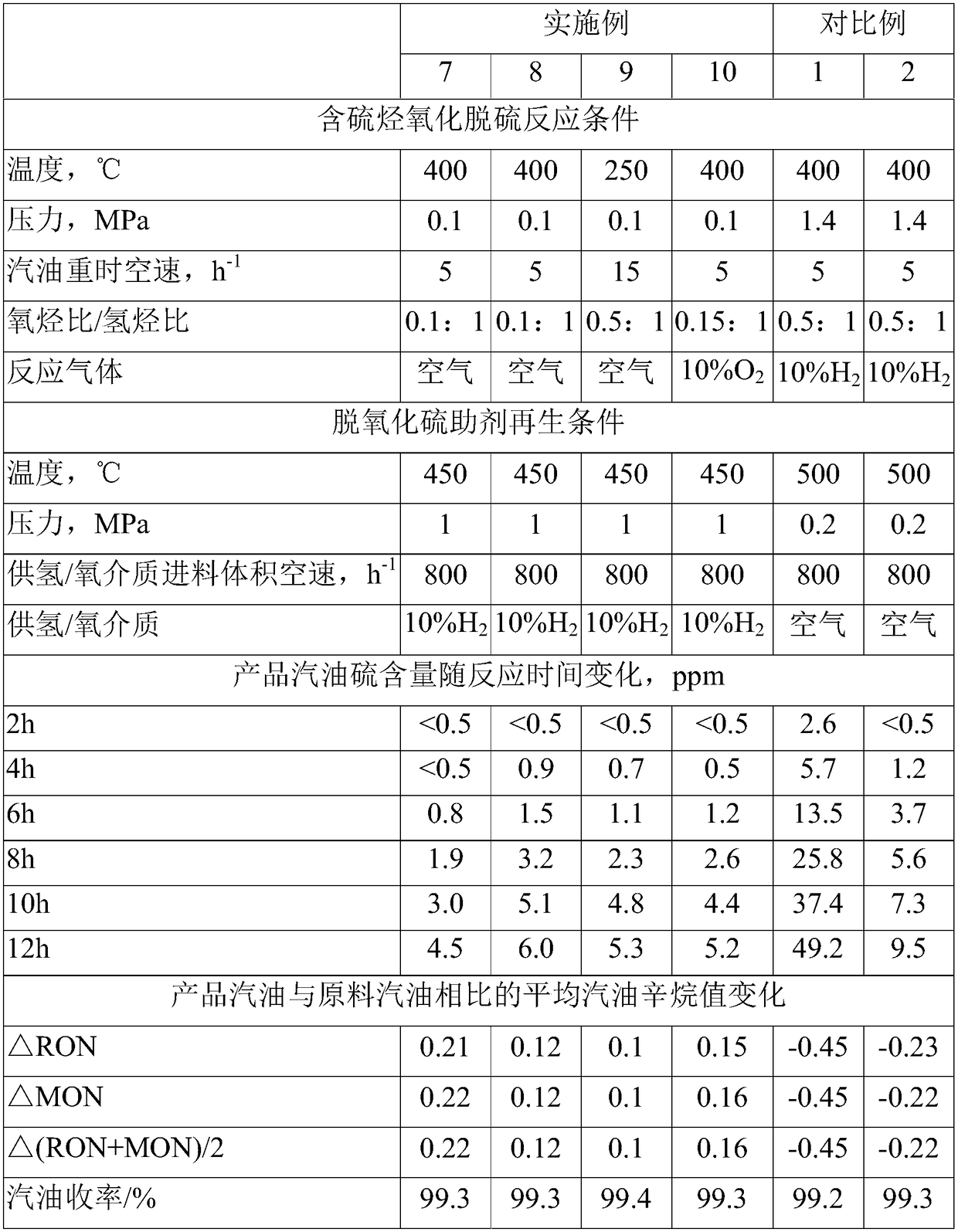

Embodiment 1

[0081] This example is used to illustrate the catalyst system and the method for oxidative desulfurization of sulfur-containing hydrocarbons of the present invention.

[0082] (1) Preparation of catalyst system (including structured catalyst and desulfurization additive).

[0083] (1) Preparation of Regular Structure Catalyst:

[0084] Coat V 2 o 5 / Al 2 o 3 The active component is coated to obtain a catalyst with a regular structure. Active component coating content is 25% by weight in the described regular structure catalyst; V in the described active component coating 2 o 5 Content is 70% by weight, Al 2 o 3 The content is 30% by weight.

[0085] (2) Preparation of desulfurization auxiliary agent:

[0086] Mix 6.38 kg of calcium oxide powder (produced by Beijing Chemical Plant, containing 6.3 kg on a dry basis) and 8.5 kg of deionized water, and stir for 30 minutes to obtain a calcium oxide slurry.

[0087] Get 1.80kg of pseudo-boehmite (produced by Shandong Alum...

Embodiment 2

[0093] This example is used to illustrate the catalyst system and the method for oxidative desulfurization of sulfur-containing hydrocarbons of the present invention.

[0094] (1) Preparation of catalyst system (including regular structure catalyst and desulfurization additive):

[0095] (1) Preparation of Regular Structure Catalyst:

[0096] Coating MoO on the cordierite honeycomb carrier (produced by Jiangsu Yixing Nonmetal Chemical Machinery Factory Co., Ltd., the carrier pore density is 200 holes / square inch, and the opening ratio is 30%) 3 / Al 2 o 3 The active component is coated to obtain a catalyst with a regular structure. The content of the active component coating in the regular structure catalyst is 20% by weight, and the active component coating is MoO 3 Content is 40% by weight, Al 2 o 3 The content is 60% by weight.

[0097] (2) Preparation of desulfurization auxiliary agent:

[0098] Mix 8.5 kg of magnesium oxide powder (produced by Beijing Chemical Plan...

Embodiment 3

[0105] This example is used to illustrate the catalyst system and the method for oxidative desulfurization of sulfur-containing hydrocarbons of the present invention.

[0106] (1) Preparation of catalyst system (including regular structure catalyst and desulfurization additive):

[0107] (1) Preparation of Regular Structure Catalyst:

[0108] Will, on the cordierite honeycomb carrier (produced by Jiangsu Yixing Nonmetal Chemical Machinery Factory Co., Ltd., the carrier pore density is 100 holes / square inch, and the opening rate is 50%), coated with WO 3 / ZrO 2 -Al 2 o 3 The active component is coated to obtain a catalyst with a regular structure. Active component coating content is 10% by weight in the regular structure catalyst; WO on the active component coating 3 The content is 70% by weight, ZrO 2 Content is 20% by weight, Al 2 o 3 The content is 10% by weight.

[0109] (2) Preparation of desulfurization auxiliary agent:

[0110] Mix 5.1 kg of magnesium oxide pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com