Magnesium alloy fixing screw capable of being degraded under control in vivo

A technology for fixing screws and magnesium alloys, applied in the field of medical devices, can solve the problems of reducing the mechanical properties and stability of materials, increasing the pH value, and low electrode potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

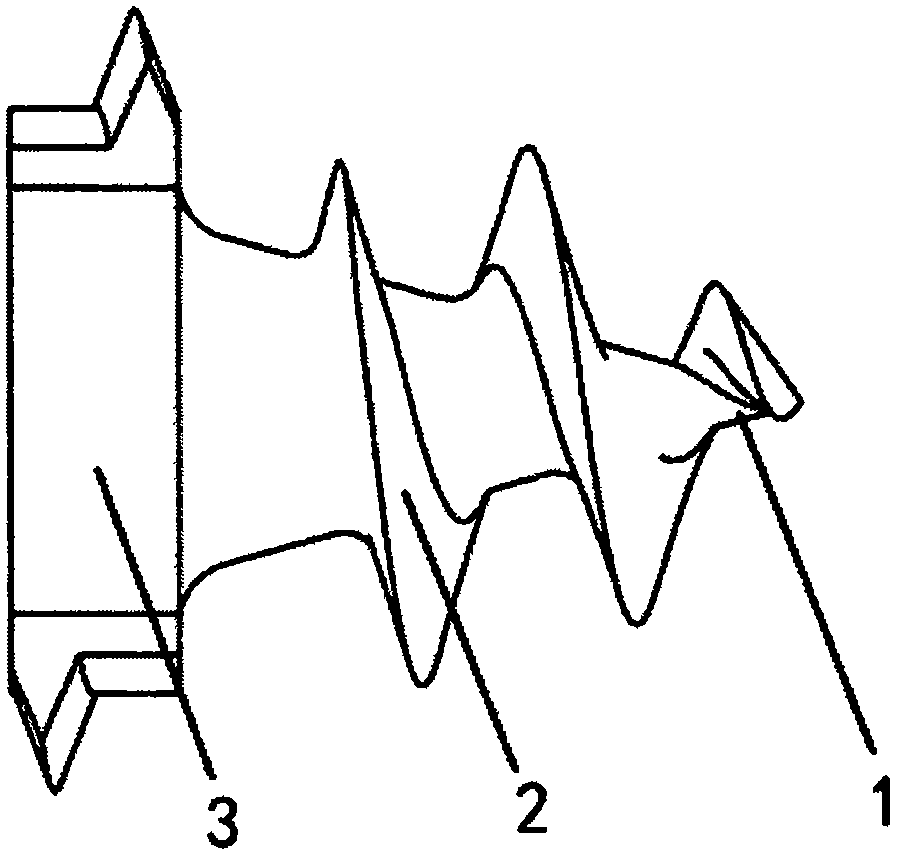

Image

Examples

Embodiment 1

[0021] Select the WE43A magnesium alloy screw body with a length of 5 mm, use sandpaper grinding and ultrasonic cleaning to remove oxides and impurities on the surface, then soak it in 50 g / L NaOH solution for 10 minutes, take it out, wash it and dry it. Then perform alternating current oxidation treatment in the oxidation treatment solution to form an oxide film layer with a thickness of about 50 μm. The composition of the oxidation treatment liquid is: 20g / L oxalic acid, 2.2g / L calcium nitrate, 1.8g / L potassium fluoride, 2.5g / L magnesium silicate and the balance water. The temperature of the oxidation treatment solution is 10°C, and the current density is 0.10A / dm 2 , the oxidation treatment time is 2 hours. Then dip in a 1.0 mg / L poly-L-lactide (PLLA) solution for 20 minutes, take it out and dry to obtain a poly-L-lactide coating with a thickness of about 10 μm.

Embodiment 2

[0023] Select the WE43A magnesium alloy screw body with a length of 5 mm, use sandpaper grinding and ultrasonic cleaning to remove oxides and impurities on the surface, then soak it in 50 g / L NaOH solution for 10 minutes, take it out, wash it and dry it. Then perform alternating current oxidation treatment in the oxidation treatment solution to form an oxide film layer with a thickness of about 50 μm. The composition of the oxidation treatment liquid is: 32g / L citric acid, 1.8g / L calcium nitrate, 1.2g / L potassium fluoride, 3.0g / L magnesium silicate and the balance water. The temperature of the oxidation treatment solution is 10°C, and the current density is 0.10A / dm 2 , the oxidation treatment time is 2 hours. Then dip in a 1.0 mg / L poly-L-lactide (PLLA) solution for 20 minutes, take it out and dry to obtain a poly-L-lactide coating with a thickness of about 10 μm.

Embodiment 3

[0025] Select the WE43A magnesium alloy screw body with a length of 5 mm, use sandpaper grinding and ultrasonic cleaning to remove oxides and impurities on the surface, then soak it in 50 g / L NaOH solution for 10 minutes, take it out, wash it and dry it. Then perform alternating current oxidation treatment in the oxidation treatment solution to form an oxide film layer with a thickness of about 50 μm. The composition of the oxidation treatment liquid is: 20g / L oxalic acid, 2.2g / L calcium nitrate, 1.8g / L potassium fluoride, 2.5g / L magnesium silicate and the balance water. The temperature of the oxidation treatment solution is 10°C, and the current density is 0.10A / dm 2 , the oxidation treatment time is 2 hours. Then dip in a 1.0 mg / L polylactic acid (PLA) solution for 20 minutes, take it out and dry to obtain a polylactic acid coating with a thickness of about 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com