Pretreatment method for neutralizing printing and dyeing waste water by using recovered carbon dioxide instead of waste acid

A technology for carbon dioxide, printing and dyeing wastewater, applied in neutralizing water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc., can solve the problems of sulfur poisoning biochemical treatment efficiency reduction, etc. The effect of carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

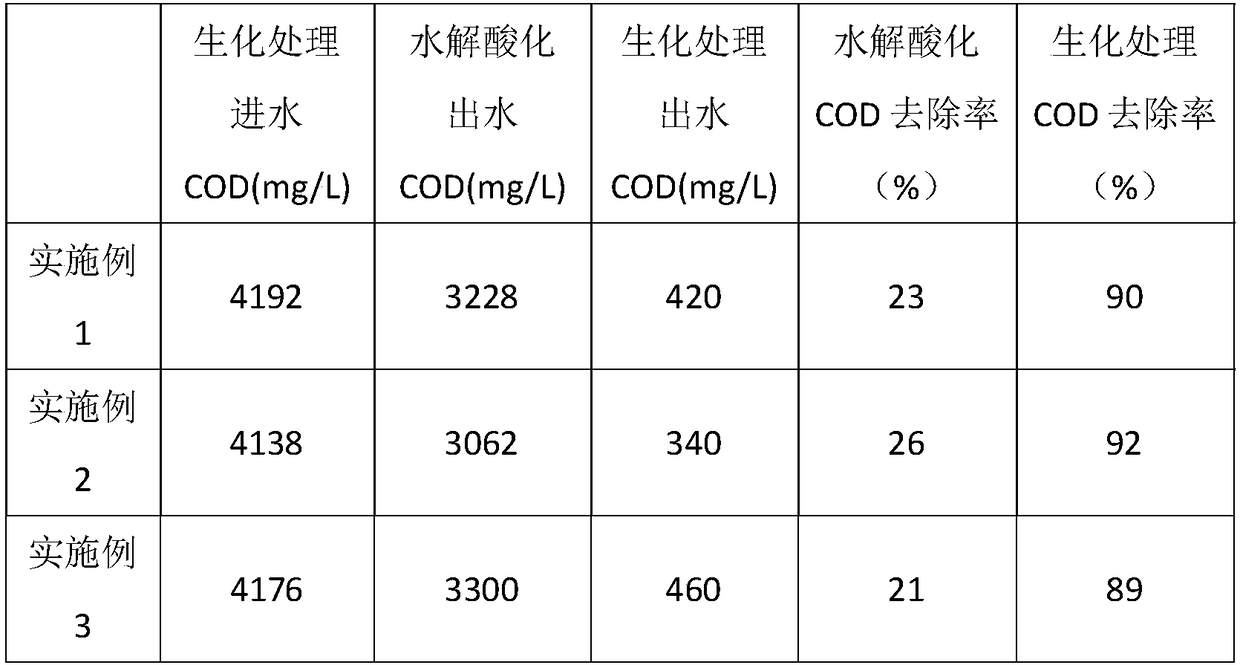

Embodiment 1

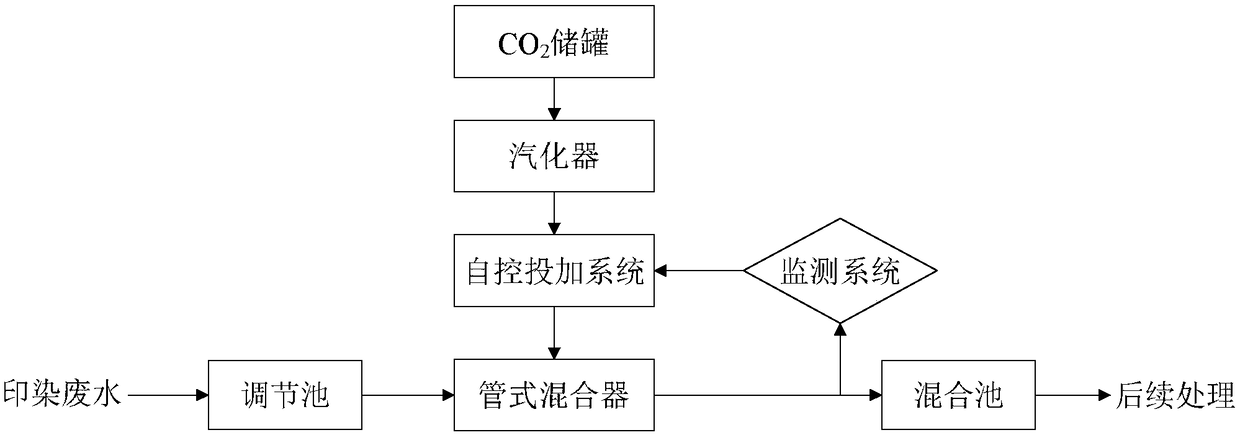

[0022] A pretreatment method for neutralizing printing and dyeing wastewater by using recycled carbon dioxide instead of waste acid:

[0023] 1) Store the carbon dioxide recovered from the waste gas in the industrial park and liquefied and purified in the carbon dioxide storage tank;

[0024] 2) After the liquid carbon dioxide is vaporized by the vaporizer, it is decompressed to 450Mpa by the pressure reducing valve, and then it is fed into the tubular mixer by the automatic control dosing system. The ventilation volume is controlled at 1L / (L min), and the outlet pressure is controlled at 3.5kg / cm 2 , the automatic control dosing system sets the pH value control to 7.5;

[0025] 3) The printing and dyeing wastewater is uniformly mixed with carbon dioxide in the tubular mixer after being regulated by the regulating tank;

[0026] 4) The printing and dyeing wastewater passes through the tubular mixer and then enters the mixing pool, so that the wastewater and carbon dioxide are...

Embodiment 2

[0028] A pretreatment method for neutralizing printing and dyeing wastewater by using recycled carbon dioxide instead of waste acid:

[0029] 1) Store the carbon dioxide recovered from the waste gas in the industrial park and liquefied and purified in the carbon dioxide storage tank;

[0030] 2) After the liquid carbon dioxide is vaporized by the vaporizer, it is decompressed to 450Mpa by the pressure reducing valve, and then it is fed into the tubular mixer by the automatic control dosing system. The ventilation volume is controlled at 2L / (L min), and the outlet pressure is controlled at 3.5kg / cm 2 , the automatic control dosing system sets the pH value control to 8.0;

[0031] 3) The printing and dyeing wastewater is uniformly mixed with carbon dioxide in the tubular mixer after being regulated by the regulating tank;

[0032] 4) The printing and dyeing wastewater passes through the tubular mixer and then enters the mixing pool, so that the wastewater and carbon dioxide are...

Embodiment 3

[0034] A pretreatment method for neutralizing printing and dyeing wastewater by using recycled carbon dioxide instead of waste acid:

[0035] 1) Store the carbon dioxide recovered from the waste gas in the industrial park and liquefied and purified in the carbon dioxide storage tank;

[0036] 2) After the liquid carbon dioxide is vaporized by the vaporizer, it is decompressed to 450Mpa by the pressure reducing valve, and then it is fed into the tubular mixer by the automatic control dosing system. The ventilation volume is controlled at 2L / (L min), and the outlet pressure is controlled at 4.5kg / cm 2 , the automatic control dosing system sets the pH value control to 8.5;

[0037] 3) The printing and dyeing wastewater is uniformly mixed with carbon dioxide in the tubular mixer after being regulated by the regulating tank;

[0038] 4) The printing and dyeing wastewater passes through the tubular mixer and then enters the mixing pool, so that the wastewater and carbon dioxide are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com