Method for synthesizing isopropyl palmitate by catalyzing mucopolysacchariden functionalized ionic liquid

A technology of isopropyl palmitate and ionic liquid, which is applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as unfavorable clean production, complex production process, cumbersome operation control, etc., and achieve Simplified reaction conditions and process, simple recovery operation, good activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

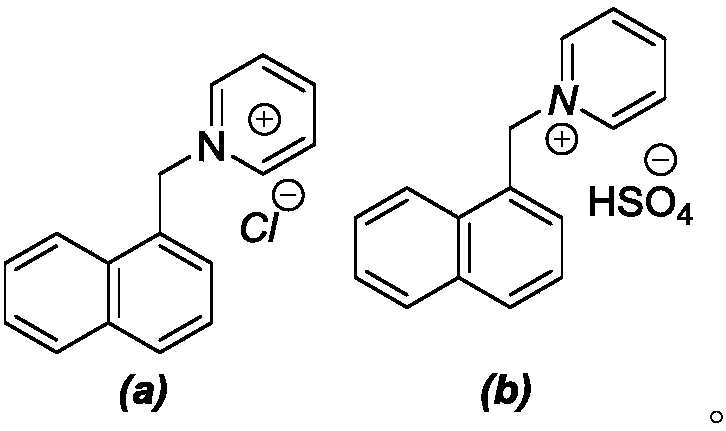

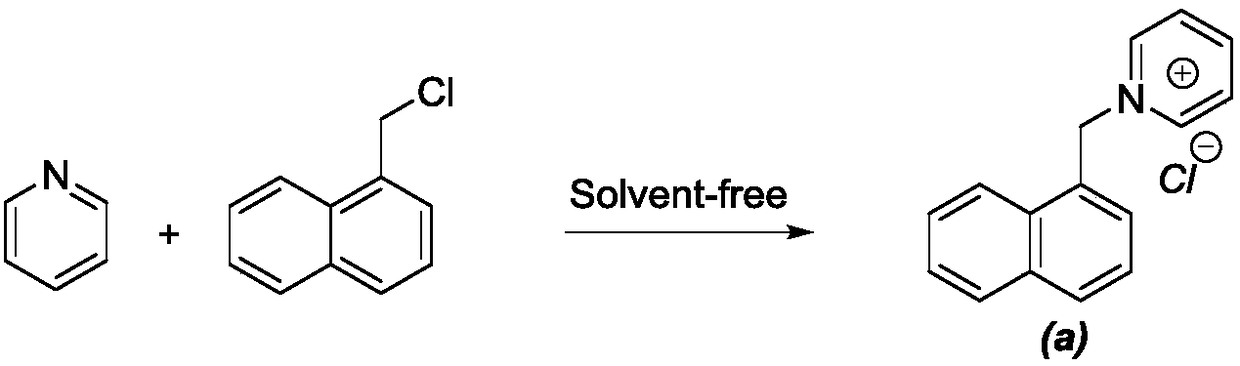

[0026] Preparation of chloride ionic liquid (a)

[0027]

[0028] Add 0.2mol (15.8g) of pyridine and 0.21mol (37.0g) of 1-chloromethylnaphthalene into a 250mL single-necked flask, mix well, control the temperature at 80°C, and react with magnetic stirring for 8h. Wash with ethyl ester for 3-6 times, filter with suction, and dry in vacuum for 24 hours to obtain the chloride ionic liquid (a).

Embodiment 2

[0030] Preparation of ionic liquid (b)

[0031]

[0032] Get 98% sulfuric acid with a mass fraction of 0.2mol and join it in a 250mL three-necked flask, add 90ml CH 2 Cl 2 , under the condition of 0±5°C, add 48g (a) of dry treated ionic liquid chloride in batches, and stir. After feeding, continue to react at this temperature for 4h, then raise the temperature to 70°C for 6h, after the reaction is completed The reaction product was allowed to stand at room temperature, and the solvent was removed by rotary evaporation, then washed with ethyl acetate for 3 to 6 times, and finally vacuum-dried for 24 hours to obtain the ionic liquid (b).

Embodiment 3

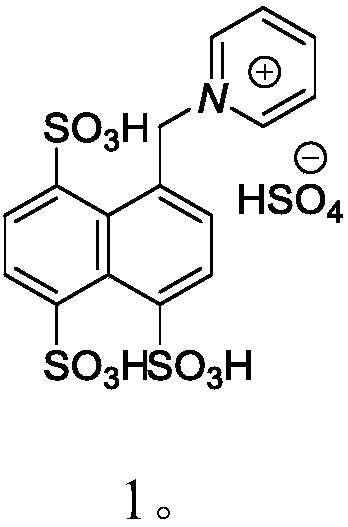

[0034] Preparation of ionic liquid (c)

[0035]

[0036] Take 0.7mol chlorosulfonic acid and put it into a 250 three-necked flask, add 90ml CH 2 Cl 2 , under the condition of 0±5°C, 60 g of the ionic liquid in Example 2 was slowly added dropwise to a 250 mL three-necked flask, and stirred. The dropwise addition is completed within 1.5~3h. After the dropwise addition, continue to react at this temperature for 4h, and then raise the temperature to 70°C for 6h. After the reaction is completed, let the reaction product stand at room temperature, remove the solvent by rotary evaporation, and then add ethyl acetate to wash. 3-6 times, and finally vacuum-dried for 24 hours to obtain the ionic liquid (c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com