Phase-change intumescent flame-retarded multi-component alkyd resin transparent finish paint and preparation method thereof

An alkyd resin, phase change expansion technology, applied in chemical instruments and methods, heat exchange materials, coatings, etc. problems, to achieve the effect of winning fire rescue and escape opportunities, reducing fire occurrence, and good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

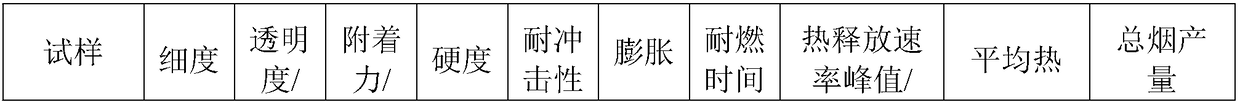

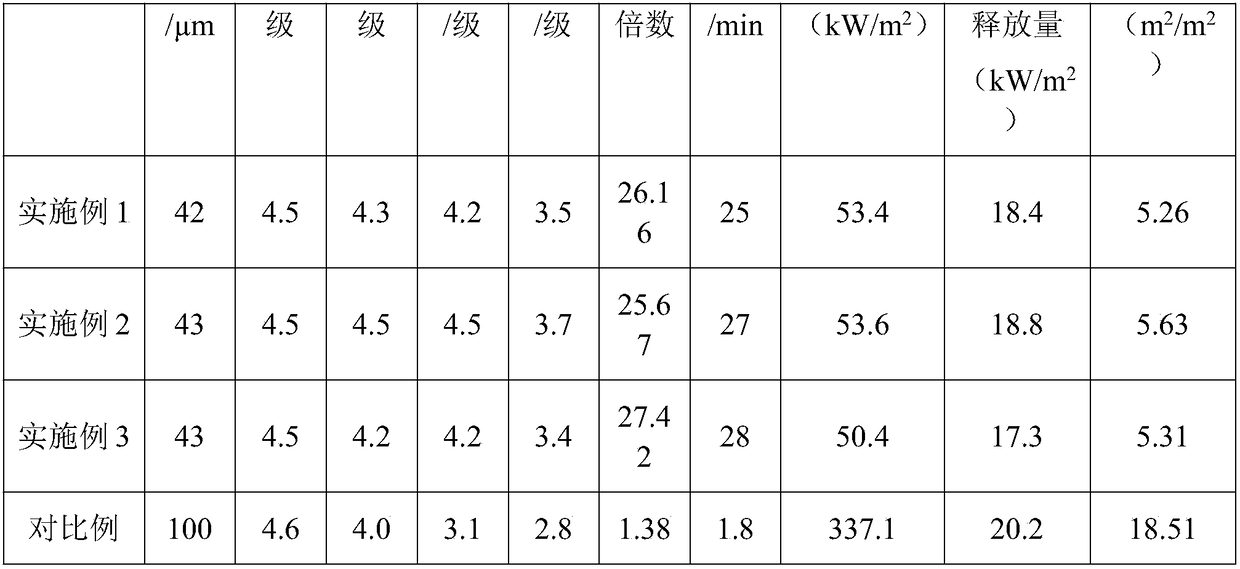

Examples

Embodiment 1

[0052] A kind of multi-component alkyd resin transparent finish paint of phase change expansion flame retardancy of the present invention, its preparation method comprises the following steps:

[0053](1) Preparation of starch phosphate: Dissolve 0.4g sodium dihydrogen phosphate, 0.8g disodium hydrogen phosphate, 1.1g hydrogen peroxide and 4.7g urea in 100g water to obtain a mixed solution, adjust to the required concentration with dilute acid or dilute alkali pH is 5.0, then sprayed into 100g of starch under stirring, continue to stir for 25min, then heat up to 65°C under low vacuum of 20kPa, oxidize and dry and dehydrate until the water content is about 10%, and the obtained product continues to stir and heat under the protection of nitrogen Phosphorylation reaction at 115°C for 1.5h, pulverized and put into a ball mill jar, vacuumed at 20kPa for 12min, filled with nitrogen for 7min, then vacuum-milled in a planetary vacuum mill for 5.0h under the protection of nitrogen filli...

Embodiment 2

[0060] A kind of multi-component alkyd resin transparent finish paint of phase change expansion flame retardancy of the present invention, its preparation method comprises the following steps:

[0061] (1) Preparation of starch phosphate: Dissolve 0.4g sodium dihydrogen phosphate, 0.8g disodium hydrogen phosphate, 1.1g hydrogen peroxide and 4.7g urea in 100g water to obtain a mixed solution, adjust to the required concentration with dilute acid or dilute alkali pH is 5.0, then sprayed into 100g of starch under stirring, continue to stir for 25min, then heat up to 65°C under low vacuum of 20kPa, oxidize and dry and dehydrate until the water content is about 10%, and the obtained product continues to stir and heat under the protection of nitrogen Phosphorylation reaction at 115°C for 1.5h, pulverized and put into a ball mill jar, vacuumed at 20kPa for 12min, filled with nitrogen for 7min, then vacuum-milled in a planetary vacuum mill for 5.0h under the protection of nitrogen fill...

Embodiment 3

[0068] A kind of multi-component alkyd resin transparent finish paint of phase change expansion flame retardancy of the present invention, its preparation method comprises the following steps:

[0069] (1) Preparation of starch phosphate: Dissolve 0.4g sodium dihydrogen phosphate, 0.8g disodium hydrogen phosphate, 1.1g hydrogen peroxide and 4.7g urea in 100g water to obtain a mixed solution, adjust to the required concentration with dilute acid or dilute alkali pH is 5.0, then sprayed into 100g of starch under stirring, continue to stir for 25min, then heat up to 65°C under low vacuum of 20kPa, oxidize and dry and dehydrate until the water content is about 10%, and the obtained product continues to stir and heat under the protection of nitrogen Phosphorylation reaction at 115°C for 1.5h, pulverized and put into a ball mill jar, vacuumed at 20kPa for 12min, filled with nitrogen for 7min, then vacuum-milled in a planetary vacuum mill for 5.0h under the protection of nitrogen fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com