Water-soluble cleaning liquid used for magnesium alloy cleaning and preparation method thereof

A water-soluble, cleaning liquid technology, applied in the field of chemical cleaning agents, can solve the problems of unstable products, not durable, insufficient cleaning power, etc., and achieve the effects of excellent anti-corrosion ability, good secondary processing performance, and improved oil washing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

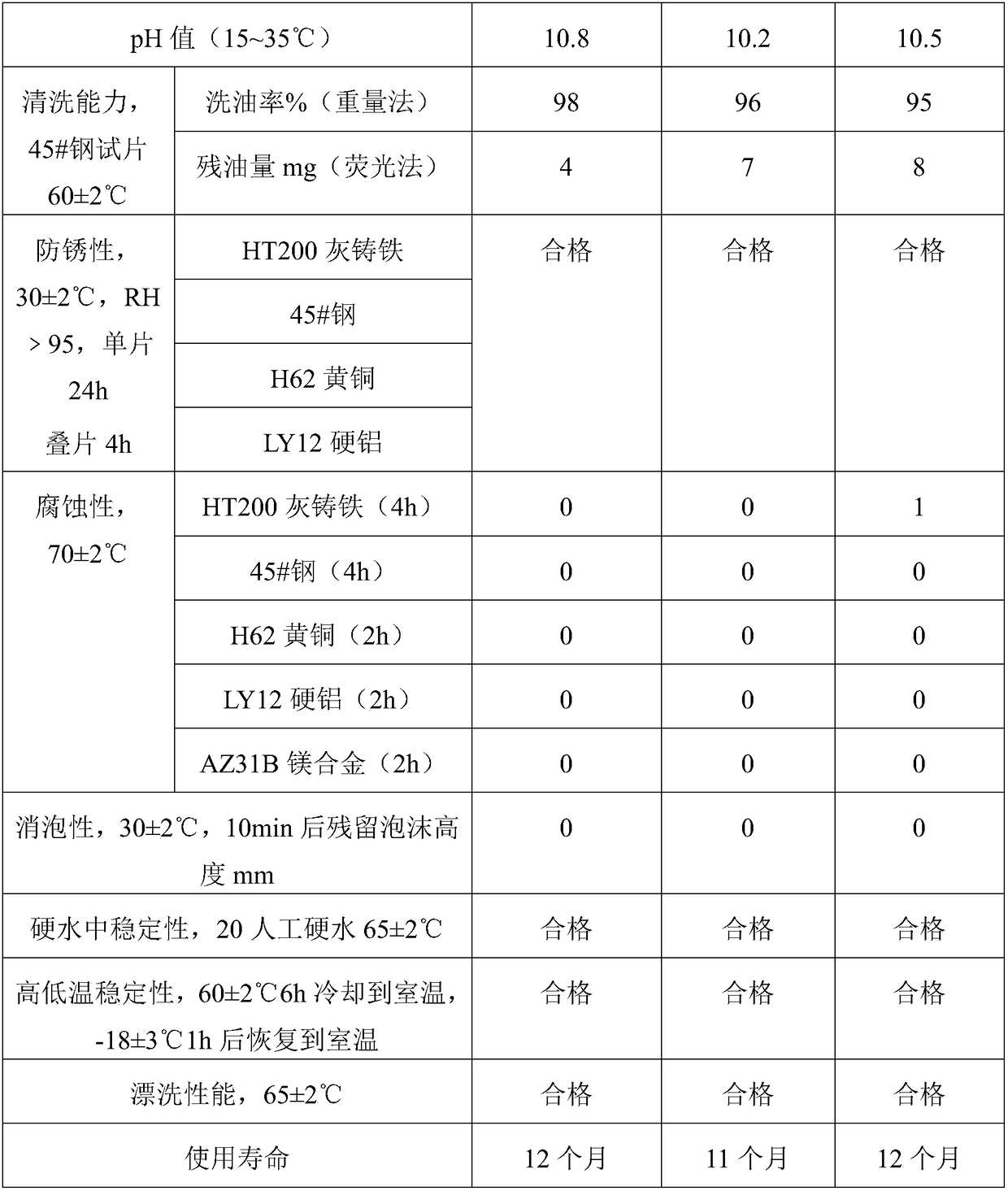

Embodiment 1

[0025] The water-soluble cleaning solution used for magnesium alloy cleaning consists of: 11g non-ionic surfactant triethanolamine oleic acid soap, 4g corrosion inhibitor (alkyl phosphate OPS-75E, sodium ethylenediamine tetramethylene phosphonate, poly Sodium acrylate, the mass ratio is 1:1:3), 7g anionic surfactant (cyclocarboxypropyl oleic acid and 5(6)-carboxy-4-hexylcyclohex-2-ene-1-octanoic acid, the mass ratio is 1:1), 3.5 pH regulator potassium hydroxide, 2.5 g chelating agent N-hydroxyethylethylenediamine triacetic acid, 72 g water.

[0026] Preparation method: Mix nonionic surfactant, corrosion inhibitor, anionic surfactant, pH regulator, chelating agent and water uniformly at room temperature.

Embodiment 2

[0028] A water-soluble cleaning solution for magnesium alloy cleaning, consisting of: 14g non-ionic surfactant nonylphenol polyoxyethylene ether, 6g corrosion inhibitor sodium molybdate, 6g anionic surfactant dimer acid, 3gpH regulator hydroxide Potassium, 3 g of chelating agent ethylene glycol-bis-(B-aminoethyl ether)-N,N-tetraacetic acid, 71 g of water.

[0029] Prepare according to the method of Example 1.

Embodiment 3

[0031] The water-soluble cleaning liquid that is used for magnesium alloy cleaning, consists of: 17g nonionic surfactant fatty alcohol polyoxyethylene ether, 8g alkyl phosphate corrosion inhibitor ASI-80, 5g anionic surfactant (octadecadiene acid dimer and 5(6)-carboxy-4-hexylcyclohex-2-ene-1-octanoic acid, mass ratio is 2: 3), 2.5gpH regulator (sodium hydroxide and methyldiethanolamine, mass ratio 3:2), 4g chelating agent amino trimethylene phosphonic acid, 67.5g water.

[0032] Prepare according to the method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com