Open-pore structure biomedical zinc material with aperture gradient distribution and preparation method thereof

A gradient distribution, biomedical technology, applied in the field of biomedical materials, can solve problems such as lack of research reports, influence on mechanical properties, fast degradation speed, etc., and achieve good three-dimensional connection, integrity protection of structure and performance, and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

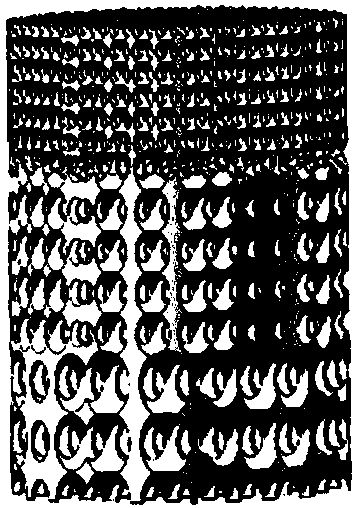

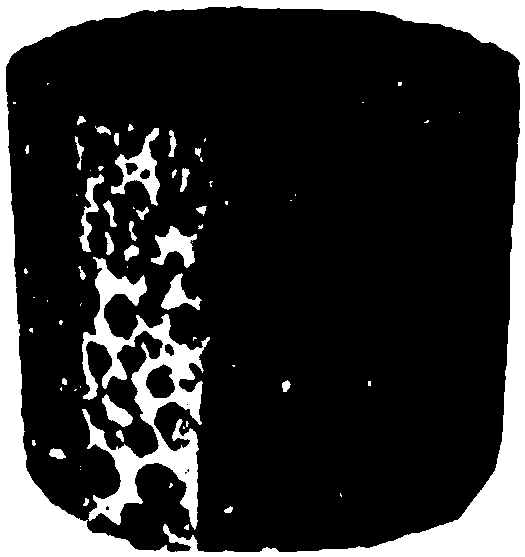

[0046] The open-pore structure biomedical zinc material with pore size gradient distribution is a zinc alloy, and the composition contains Al1%, Mg3%, Ca 0.05%, Zr 0.2% by mass percentage, and the balance is Zn and unavoidable impurities; the surface and internal distribution of the material There are interconnected openings, the shape of the opening is mainly spherical, the diameter of the opening is 0.5-6mm, and the inner diameter of the opening is distributed along the axial direction in a unidirectional gradient, the compressive strength is 20MPa, and the elastic modulus is 10GPa ; Wherein the interconnected openings are connected through interconnecting pores, and the number of interconnecting pores connected by each opening is 1 to 8; its porosity is 60%; the three-dimensional structure schematic diagram is as follows figure 1 As shown, the actual figure 2 As shown, the material from top to bottom is small pore area, medium pore area and large pore area, and the thickne...

Embodiment 2

[0055] The open-pore structure biomedical zinc material with pore size gradient distribution is a zinc alloy, and the composition contains Al5%, Mg0.01%, Ca 3%, Zr 0.05% by mass percentage, and the balance is Zn and unavoidable impurities; the surface of the material and There are interconnected openings distributed inside, the shape of the opening is mainly spherical, the diameter of the opening is 0.5-6mm, and the inner diameter of the opening is distributed in a two-way gradient along the axial direction; its compressive strength is 15MPa, and the elastic modulus is 8GPa; interconnected openings are connected through interconnected pores, and the number of interconnected pores connected by each opening is 1 to 8; its porosity is 65%; the material is small pore area, medium pore area, Large pore area, medium pore area and small pore area, there are 5 areas in total, each area has the same thickness; the appearance is cylindrical;

[0056] Method is with embodiment 1, and dif...

Embodiment 3

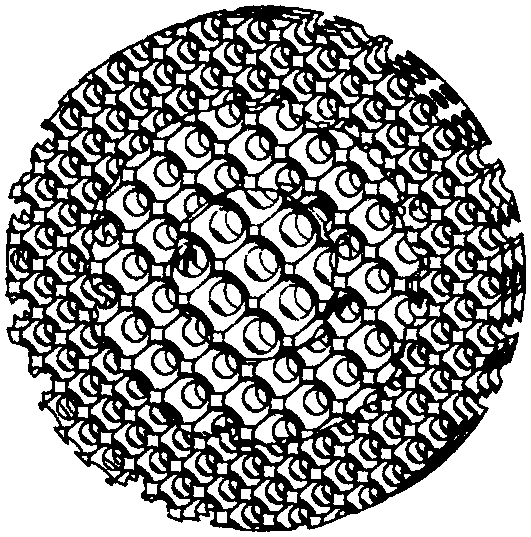

[0062] The open-pore structure biomedical zinc material with pore size gradient distribution is a zinc alloy, and the composition contains Al3%, Mg1%, Ca 1%, Zr 0.1% by mass percentage, and the balance is Zn and unavoidable impurities; the surface and internal distribution of the material There are interconnected openings, the shape of the opening is mainly spherical, the diameter of the opening is 0.5-6mm, and the inner diameter of the opening is distributed in a gradient along the radial direction; its compressive strength is 10MPa, and the elastic modulus is 5GPa; The connected openings are connected through the connecting holes, and the number of connecting holes connected by each opening is 1 to 8; the porosity is 70%; the three-dimensional structure schematic diagram is as follows image 3 As shown, the actual Figure 4 As shown, the material from the edge to the middle is the small pore area, the medium pore area and the large pore area, and the width of each area is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com