A semi-permanent silicone release agent and preparation method thereof

A semi-permanent, silicone technology, applied in the manufacturing field, can solve the problems of increasing the emission of volatile organic compounds, destroying the surface integrity of the product, reducing the service life of the mold, etc., to improve the storage stability, improve the demoulding efficiency, and improve the use. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

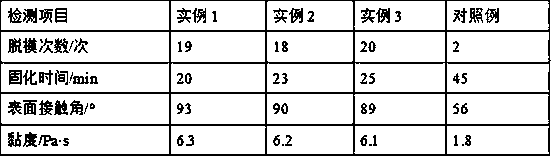

Examples

example 1

[0027] Take 50g of perfluoropolyether and put it into a three-necked flask, then add 240mL of deionized water, stir at 300r / min and raise the temperature to 60°C, keep it warm for 4 hours, put it into a rotary evaporator, evaporate under reduced pressure to remove water and hydrofluoric acid, To obtain perfluoropolyether carboxylic acid, take 5 g of perfluoropolyether carboxylic acid, 3 g of trifluoroethyl methacrylate, 1 g of sodium perfluorooctanoate, and 2 g of sodium perfluorooctane sulfonate, add them to 50 g of acetone, and stir at 300 r / min for 20 min , to obtain the fluorinated modified solution, get 15g tetramethyldisiloxane, 24g methyltrimethoxysilane, 18g phenyltrimethoxysilane, 5g ethyl orthosilicate, and put 50g fluorinated modified solution into the reaction In the still, stir at 200r / min for 20min, then add 18mL of deionized water, 20g of absolute ethanol, 0.20g of hydrochloric acid with a mass fraction of 10%, and react at 80°C for 5h. Distill the low boilers u...

example 2

[0029] Take 55g of perfluoropolyether and put it into a three-neck flask, then add 280mL of deionized water, stir at 360r / min and raise the temperature to 70°C, keep it warm for 4 hours, put it into a rotary evaporator, evaporate under reduced pressure to remove water and hydrofluoric acid, To obtain perfluoropolyether carboxylic acid, take 5g of perfluoropolyether carboxylic acid, 4g of trifluoroethyl methacrylate, 1g of sodium perfluorooctanoate, and 2g of sodium perfluorooctane sulfonate, add them to 60g of acetone, and stir at 360r / min for 25min , to obtain the fluorinated modified solution, get 20g tetramethyldisiloxane, 30g methyltrimethoxysilane, 25g phenyltrimethoxysilane, 10g ethyl orthosilicate, and put 55g fluorinated modified solution into the reaction In the still, stir at 240r / min for 25min, then add 20mL deionized water, 25g absolute ethanol, 0.24g mass fraction of 10% hydrochloric acid, react at 85°C for 6h, put it into a rotary evaporator after the reaction is ...

example 3

[0031]Take 60g of perfluoropolyether and put it into a three-necked bottle, then add 300mL of deionized water, stir at 400r / min and raise the temperature to 80°C, keep it warm for 5 hours, put it into a rotary evaporator, evaporate under reduced pressure to remove water and hydrofluoric acid, To obtain perfluoropolyether carboxylic acid, take 6g of perfluoropolyether carboxylic acid, 5g of trifluoroethyl methacrylate, 2g of sodium perfluorooctanoate, and 3g of sodium perfluorooctane sulfonate, add them to 80g of acetone, and stir at 400r / min for 30min , to obtain the fluorinated modified solution, get 25g tetramethyldisiloxane, 36g methyltrimethoxysilane, 32g phenyltrimethoxysilane, 15g ethyl orthosilicate, and put 60g fluorinated modified solution into the reaction In the still, stir at 300r / min for 30min, then add 25mL of deionized water, 30g of absolute ethanol, 0.25g of hydrochloric acid with a mass fraction of 10%, and react at 90°C for 8h. Distill the low boilers under r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com