PC-PVC composite plate and a production process thereof

A composite board and composite board technology, applied in the direction of synthetic resin layered products, layered products, lamination, etc., can solve problems such as large limitations, and achieve the effects of simple equipment, environmental protection, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

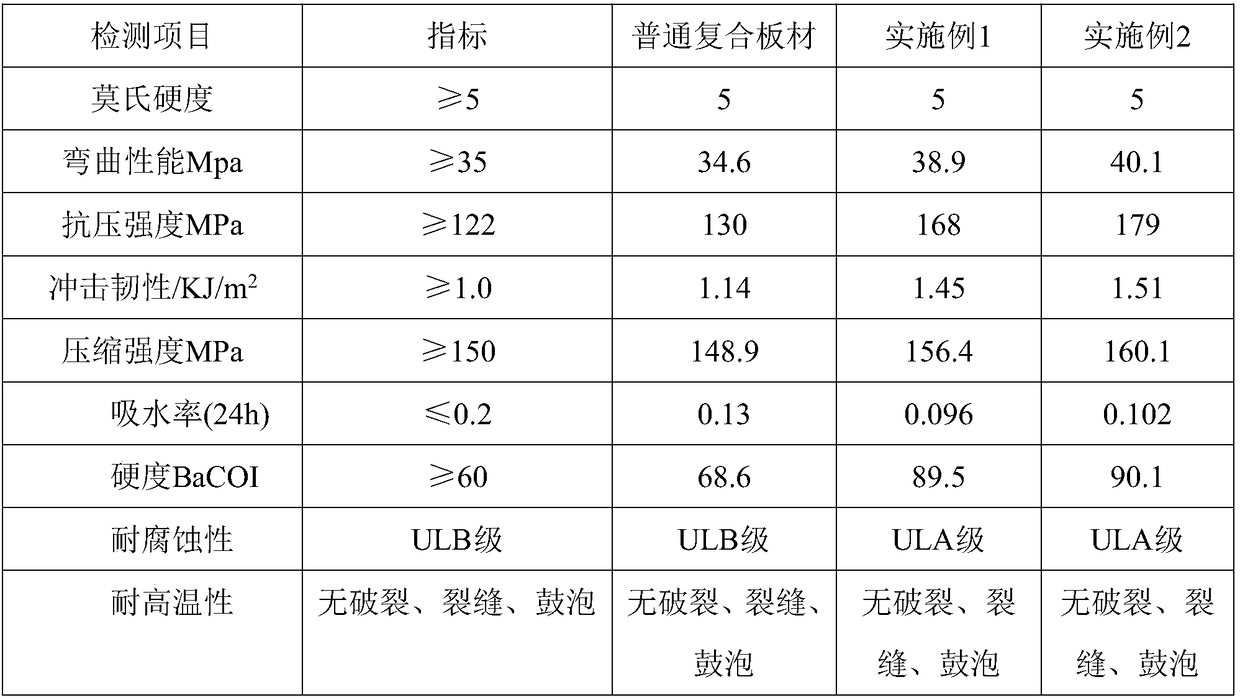

Examples

Embodiment 1

[0040] A PC and PVC composite board and its production process;

[0041] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0042] A PC and PVC composite board and its production process, comprising the following steps:

[0043] (1) Butadiene rubber and nano-modified alkyd resin are added in the mixed acid solution of 80 times of its weight, and the mixed acid is composed of 60% carbonic acid and 87% hydrochloric acid solution with a mass ratio of 3:1, Sonicate at 55°C for 17 minutes, filter, wash the precipitate twice with water, and dry in vacuum at 70°C for 30 minutes to obtain acidified modified butylpyridine rubber;

[0044] (2) Get 47% of the weight of the above-mentioned acidified modified butylpyridine rubber, mix it with easy-to-mix tank black, foam regulator DLF, vaseline, light calcium carbonate, antimony trioxide, zinc carbonate, and add to the mixture weight 70 In N-cyclohexyl-2-benzothiazole sulfen...

Embodiment 2

[0058] A PC and PVC composite board and its production process;

[0059] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0060] The prepared PC and PVC composite board Chen Hua method comprises the following steps:

[0061] Fix the newly produced PC and PVC composite boards. When arranging the boards, the partitions should be kept flush with both ends of the PC and PVC composite boards, and the upper and lower partitions should be kept vertical to prevent excessive moisture at the ends of the PC and PVC composite boards. Dissipation, uneven shrinkage leads to end cracks, and the upper and lower partitions are kept vertical to prevent the PC and PVC composite boards from bearing gravity balance or not to prevent warping; and each PC and PVC composite boards are arranged alternately, and each PC and PVC composite board at the same level Leave 0.8cm between the composite boards; for PC and PVC composite boards of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com