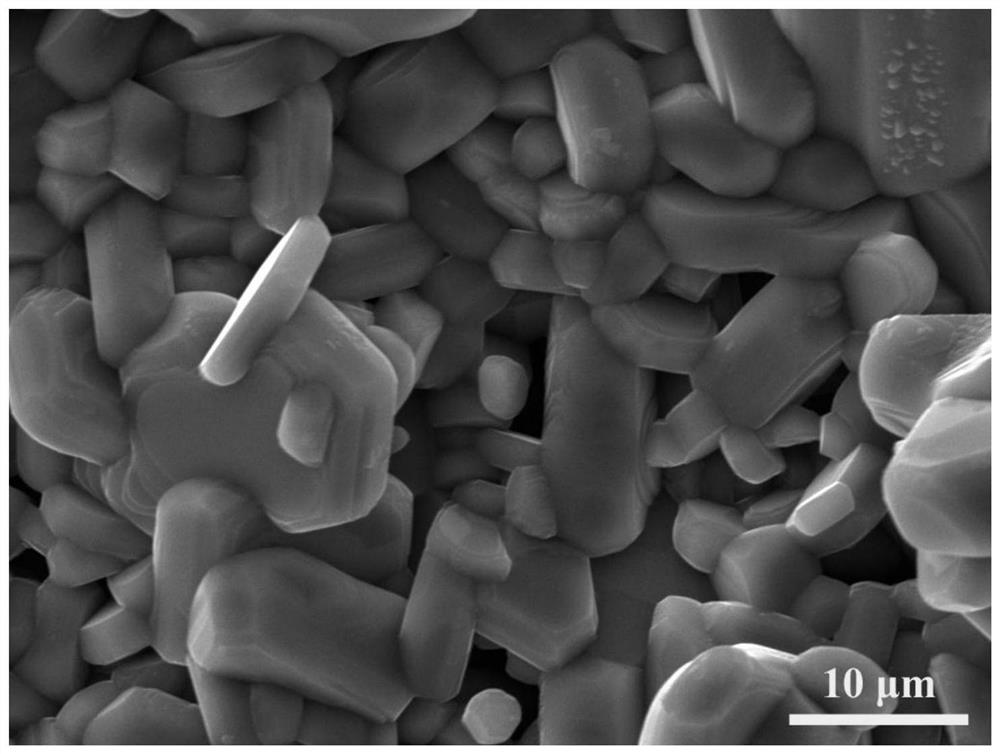

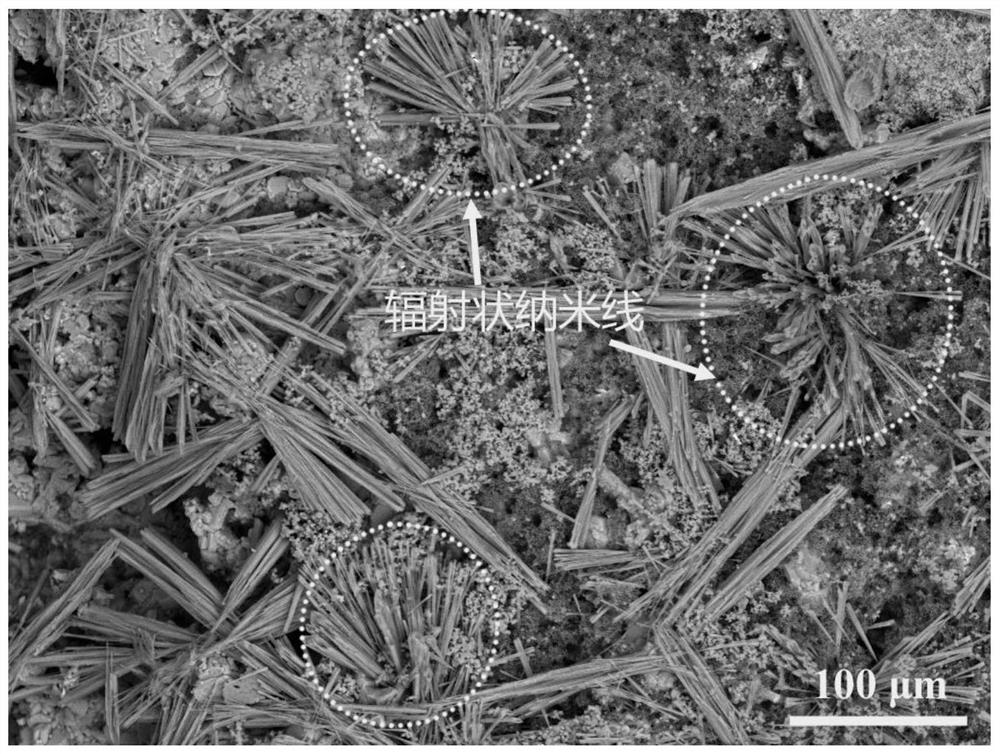

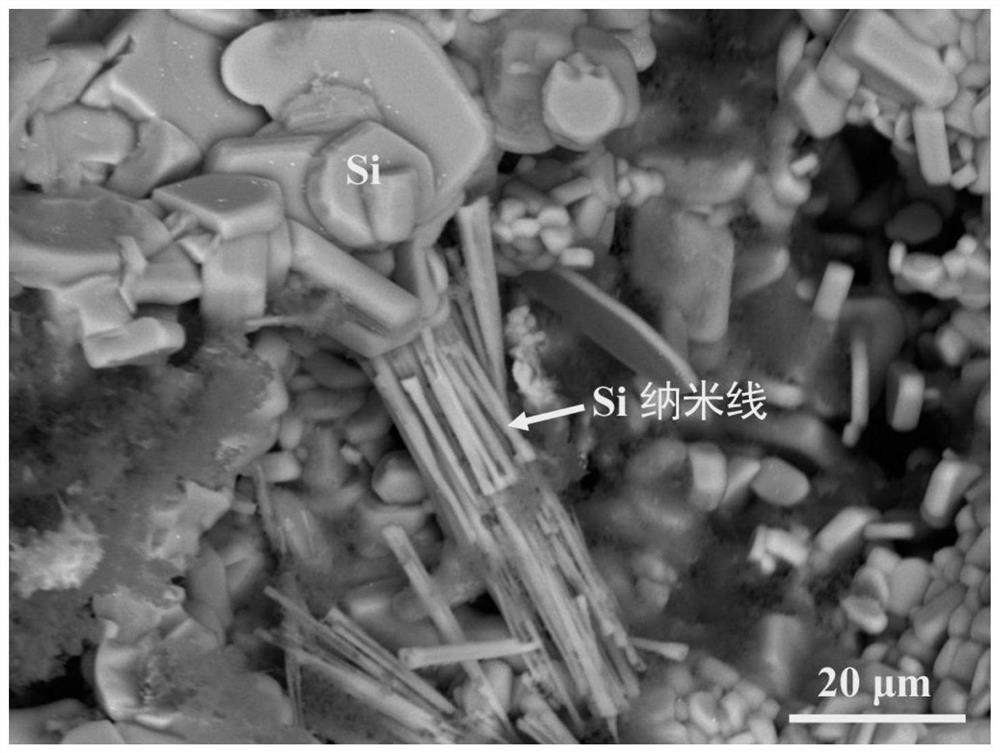

Radial nanowires grown on the surface of a c/c-si composite material and its preparation method at room temperature

A composite material and surface growth technology, which is used in the field of growing radial nanowires on the surface of C/C-Si composite materials and the preparation at room temperature, can solve the mechanical property damage of carbon/carbon composite materials, small binding force, and nanowires. easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Pretreatment of Carbon / Carbon Composite

[0043] Set the density to 1.74g / cm 3 The carbon / carbon composite materials were polished and polished with No. 180, No. 320 and No. 400 sandpaper in sequence, then ultrasonically cleaned with water and absolute ethanol for 30 minutes, and dried in an 80°C drying oven for 12 hours for later use;

[0044] Step 2: Preparation of Si coating on carbon / carbon composite surface

[0045] 1) Weigh respectively Si powder with a mass percentage of 90%, 10% Al 2 o 3 powder, placed in a turpentine ball ink tank, ball milled for 4 hours, and dried in an 80°C drying oven for 12 hours before use;

[0046] 2) Spread the mixed powder prepared in 1) in the graphite crucible, the thickness of the powder is about 1 / 2 of the height of the graphite crucible. Then put the pretreated carbon / carbon composite material into a graphite crucible, and then cover the carbon / carbon composite material with mixed powder, the thickness of which is abou...

Embodiment 2

[0063] Step 1: Pretreatment of Carbon / Carbon Composite

[0064] Set the density to 1.72g / cm 3 The carbon / carbon composite materials were polished and polished with No. 180, No. 320 and No. 400 sandpaper in sequence, then ultrasonically cleaned with water and absolute ethanol for 35 minutes, and dried in an 80°C drying oven for 24 hours for later use;

[0065] Step 2: Preparation of Si coating on carbon / carbon composite surface

[0066] 1) Take by weight respectively Si powder with mass percentage of 85%, Al with 15% 2 o 3 powder, placed in a turpentine ball ink tank, ball milled for 3 hours, dried in a 70°C drying oven for 24 hours, and then used;

[0067] 2) Spread the mixed powder prepared in 1) in the graphite crucible, the thickness of the powder is about 1 / 2 of the height of the graphite crucible. Then put the pretreated carbon / carbon composite material into a graphite crucible, and then cover the carbon / carbon composite material with mixed powder, the thickness of wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com