A kind of synthetic method of 2,2'-bisdiphenylphosphino-1,1'-binaphthalene

A technology of diphenylphosphino group and synthesis method, which is applied in the field of synthesis of 2,2'-bis-diphenylphosphino-1,1'-binaphthyl, can solve the problems of high production cost, great difficulty in operation and the like , to achieve the effect of low price, strong industrial application prospects, and easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Synthesis of 2,2'-bisethoxy-1,1'-binaphthalene

[0032] In a 50L glass reactor equipped with a reflux condenser and mechanical stirring, add 5.7Kg binaphthyldiol, 4.7Kg iodoethane, 8.3Kg potassium carbonate and 30L acetonitrile, heat to 80°C under stirring, and react for 12 hours. After the reaction solution returns to room temperature, remove potassium carbonate by filtration, concentrate acetonitrile to obtain the crude product 2,2'-bisethoxy-1,1'-binaphthalene, wash with water, and then dry in vacuum to obtain a white solid 2,2'- Diethoxy-1,1'-binaphthalene 6.3Kg, yield 92%. The acetonitrile solvent concentrated by distillation is retained and can be used in the next batch.

[0033] (2) Synthesis of 2,2'-bisdiphenylphosphino-1,1'-binaphthyl

[0034] In a 50L glass reactor equipped with a reflux condenser and mechanical stirring, add 3.4Kg of 2,2'-bisethoxy-1,1'-binaphthalene prepared in the above step (1), and 350g of lithium metal flakes, 5.8kg of tetramethyl...

Embodiment 2

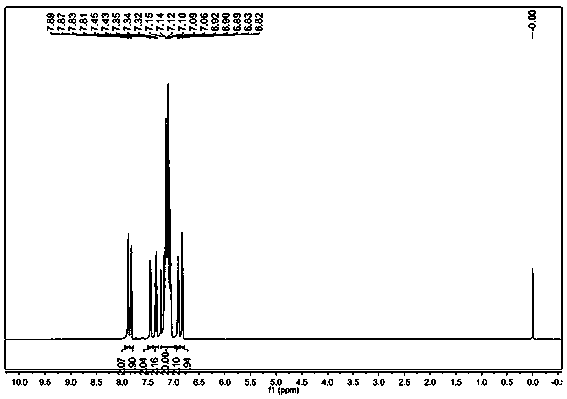

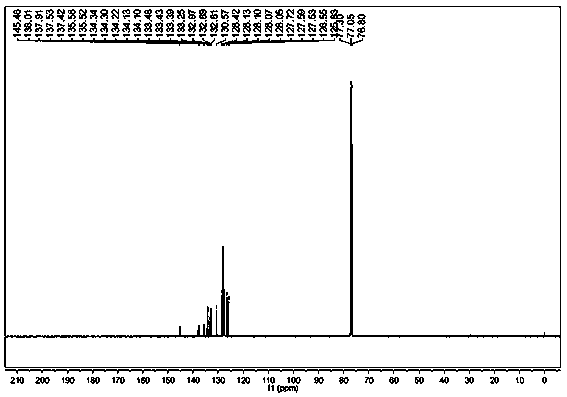

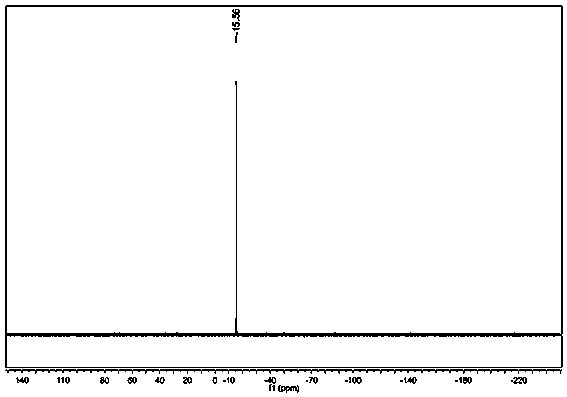

[0036] In a 50L glass reactor equipped with a reflux condenser and mechanical stirring, add 3.4Kg of 2,2'-bisethoxy-1,1'-binaphthalene prepared in step (1) of Example 1, and 350g of lithium metal Tablets, 5.8kg tetramethylethylenediamine and 30L dibutyl ether, heated to 140°C under stirring, reacted for 6 hours, lowered to 0°C, added dropwise 8.8Kg diphenylphosphine chloride, and then added 900g water to quench reaction. Concentrate the product solution, filter and wash with methanol, then vacuum-dry to obtain off-white solid 5.8Kg, the product is passed through 1 H-NMR, 13 C-NMR and 31 P-NMR confirmed the structure as 2,2'-bisdiphenylphosphino-1,1'-binaphthyl, the yield was 93%, and the purity of the product analyzed by liquid chromatography was 99.6%.

Embodiment 3

[0038]In a 50L glass reactor equipped with a reflux condenser and mechanical stirring, add 3.4Kg of 2,2'-bisethoxy-1,1'-binaphthalene prepared in step (1) of Example 1, and 350g of lithium metal Tablets, 5.8kg tetramethylethylenediamine and 30L dioxane, heated to 100°C under stirring, after 8 hours of reaction, lowered to 0°C, added dropwise 8.8Kg diphenylphosphine chloride, and then added 900g water to quench extinction reaction. Concentrate the product solution, filter and wash with methanol, then vacuum-dry to obtain off-white solid 5.9Kg, the product is passed through 1 H-NMR, 13 C-NMR and 31 P-NMR confirmed the structure as 2,2'-bisdiphenylphosphino-1,1'-binaphthyl, the yield was 95%, and the purity of the product analyzed by liquid chromatography was 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com