Inorganic composite coating, method for coating surface of building material by applying same and building material

A technology of building material surface and coating, which is applied in the direction of surface coating liquid device, fireproof coating, pretreatment surface, etc. It can solve the problems of high loss rate, non-wear resistance, and large human injury, so as to ensure product safety, Guaranteed service life and good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

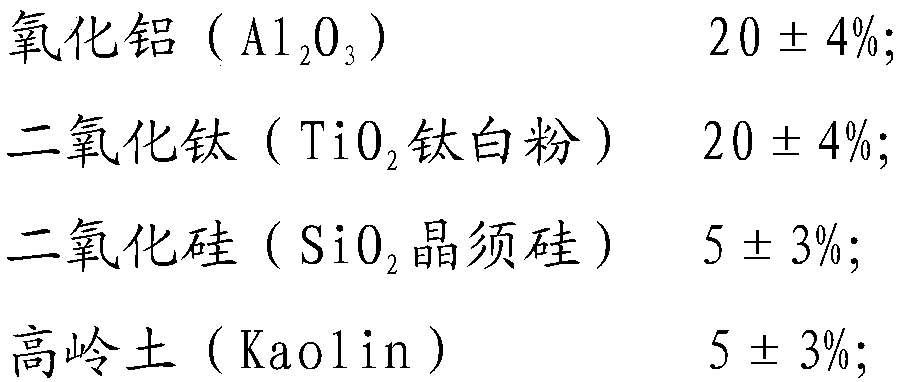

[0031] This embodiment provides an inorganic composite coating that can be applied in the field of building materials. The coating composition includes A component and B component that are separately packaged and used in combination, and the B component is an inorganic film-forming accelerator. The A component includes alumina, titanium dioxide, silicon dioxide, kaolin, resin solution and organic solvent; wherein the weight ratio of each component by weight percentage is as follows:

[0032]

[0033]

[0034] In this embodiment, the resin component of the above resin solution may be epoxy resin or polyurethane resin, etc., and contains nano-silica, alumina and zirconia. The organic solvent can be any one or a mixture of isopropanol, butanol, ethanol or propylene glycol methyl ether acetate. The inorganic film-forming accelerator in this embodiment is preferably silicon dioxide.

[0035] As a preferred solution of this embodiment, this embodiment provides a preferred for...

Embodiment 2

[0041] This embodiment provides a building material, including a base material and a coating layer coated on the surface of the base material. The composition formula of the coating layer can be seen in the first embodiment above, and the specific coating process will be described later. According to different usage environments, the base material can be metal, ceramics, engineering plastics and the like. This building material can be used in indoor or outdoor household, industrial, military, etc. For example, due to the safety, environmental protection and strong non-stickiness of the above-mentioned inorganic composite coatings, it can be used for surface coatings on household kitchen utensils, heating vessels or heating pipes, etc. .

[0042] The following introduces the coating process of applying the above-mentioned inorganic composite coating.

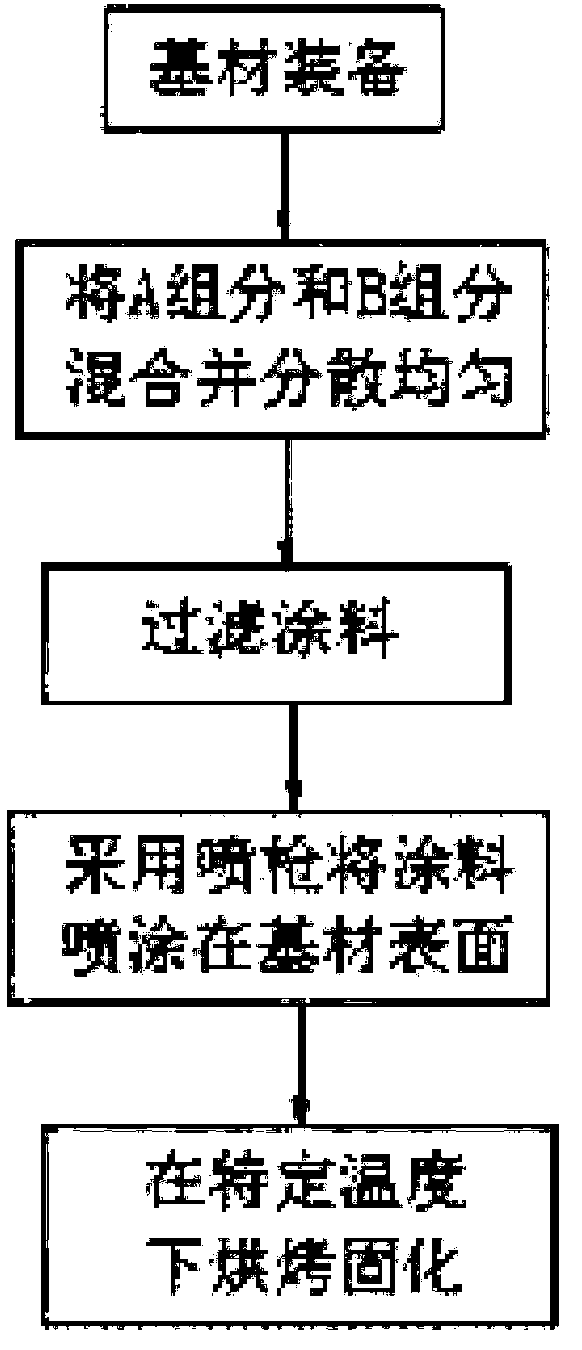

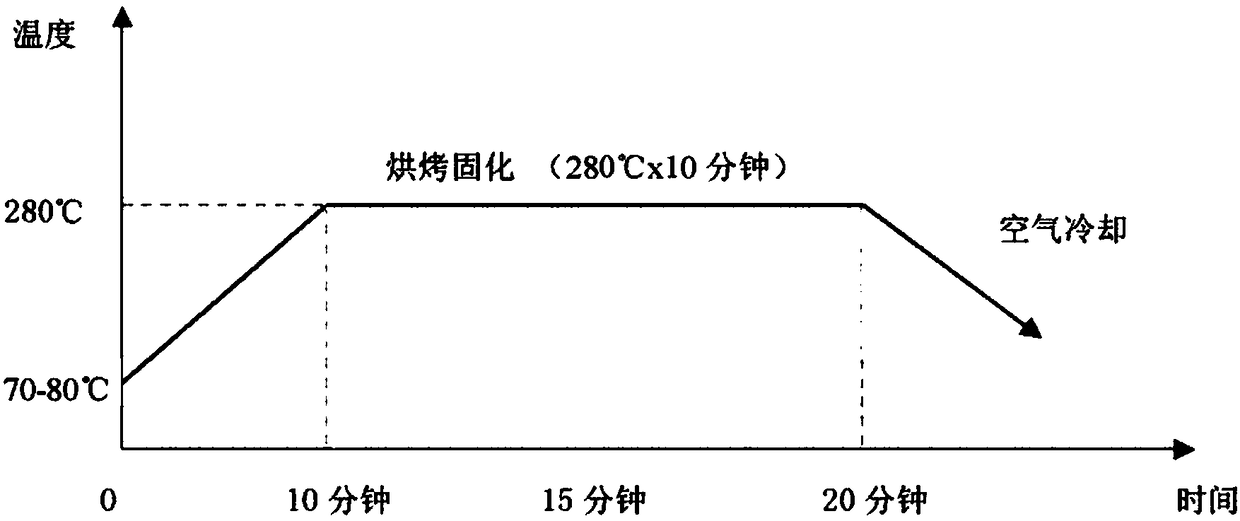

[0043] see figure 1 As shown, the method for coating the surface of building materials comprises the following steps:

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com