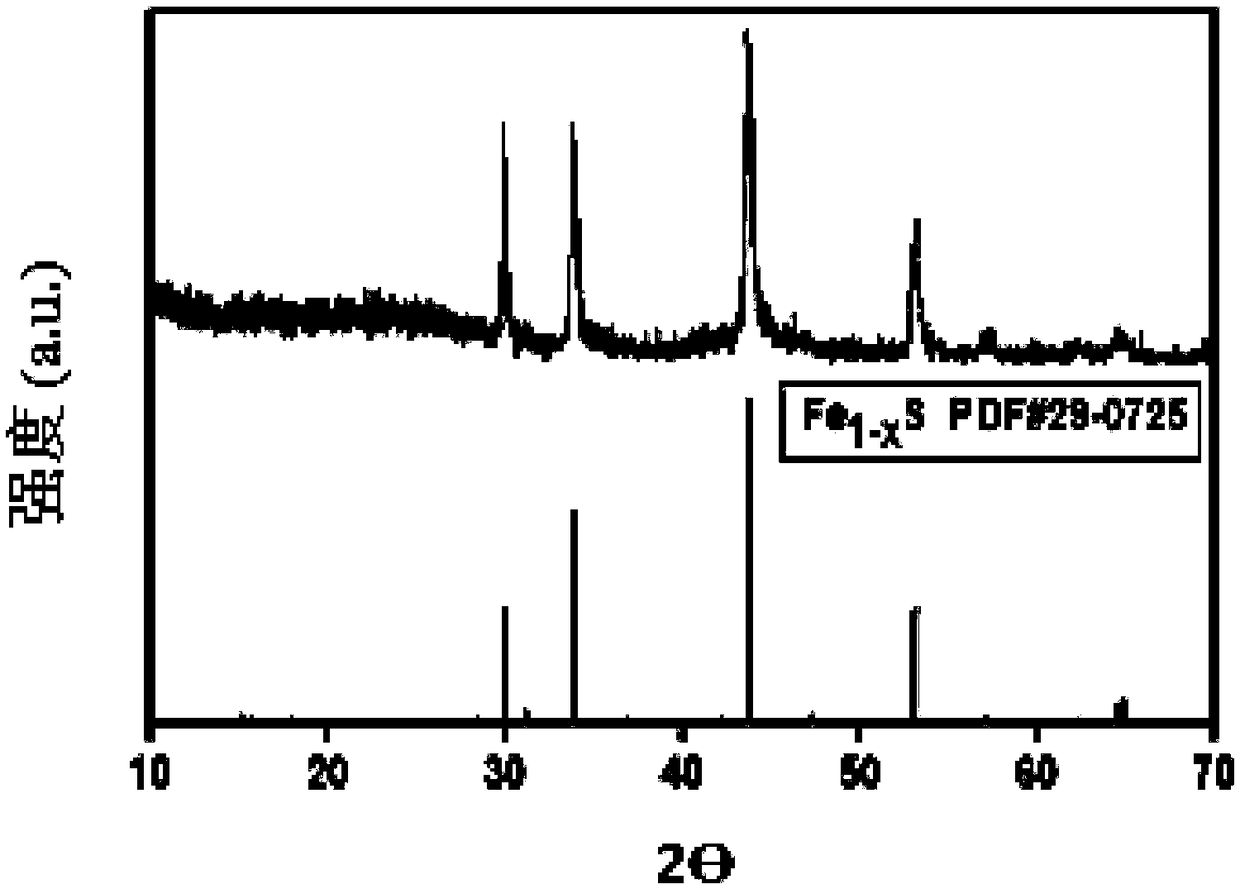

Preparation method of Li/Na ion battery anode material Fe<1-x>S/C

A technology for sodium ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high pollution degree and difficult wastewater treatment, and achieve the effects of high synthesis efficiency, effective reuse and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

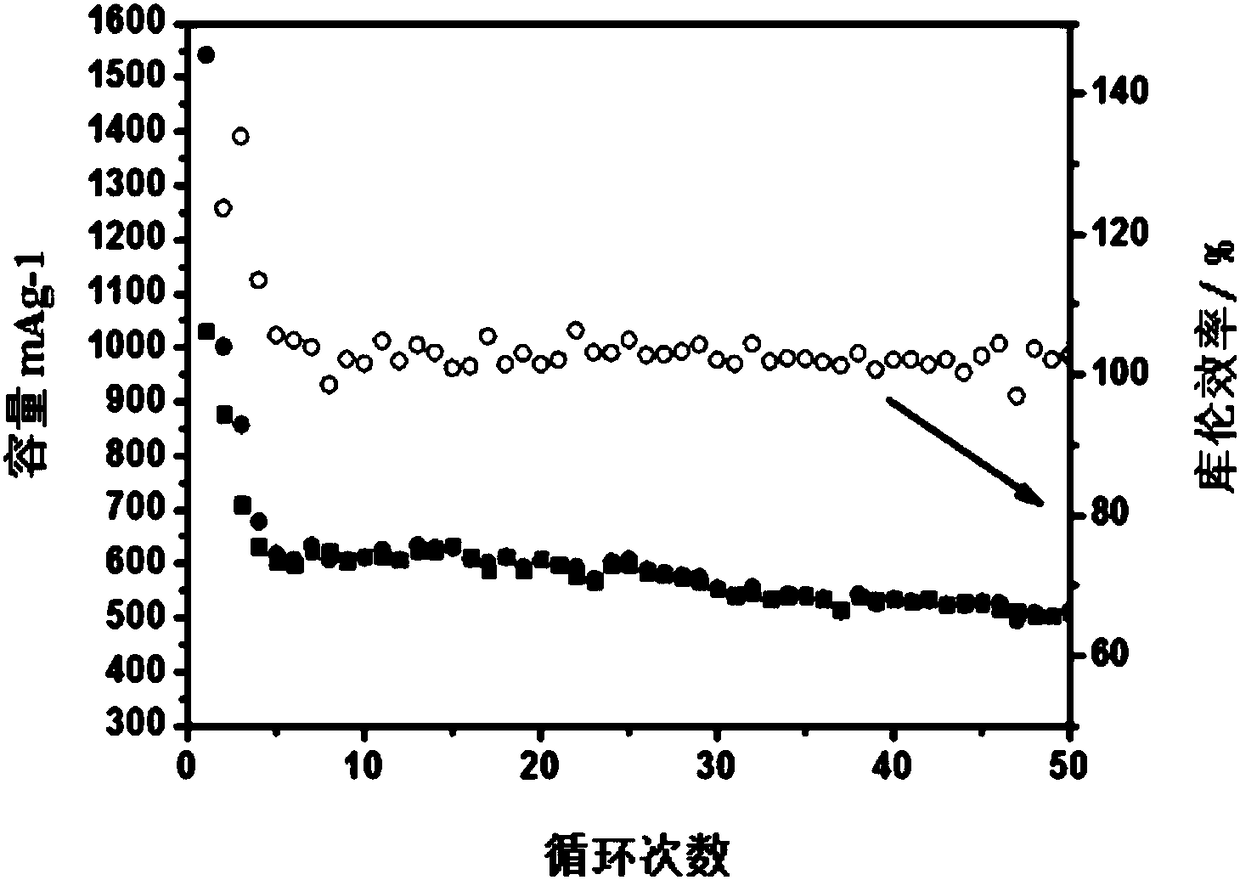

[0045] A kind of lithium / sodium ion battery anode material Fe 1-x The preparation method of S / C comprises steps as follows:

[0046] Take 10mL of sulfur-containing petroleum sewage into a three-necked flask, add 1.5ml of 15wt℅ hydrogen peroxide aqueous solution, and stir at 50°C for 30min to obtain pretreated sulfur-containing petroleum sewage; then add 30mL of 0.1mol L -1 The ferric chloride aqueous solution is slowly added dropwise to the above-mentioned pretreated sulfur-containing petroleum sewage, continuously stirred and added 2ml 2wt℅ethylenediammonium tetraacetic acid aqueous solution to make the pH value to 4, and stirred at room temperature for 2h to obtain a uniform mixed solution; The mixed solution was put into a reaction kettle, hydrothermally treated at 180°C for 24 hours, then naturally cooled to room temperature, and the precipitate obtained by centrifugation was dried at 60°C to obtain a black powder; the black powder was washed twice with water and then wash...

Embodiment 2

[0053] A kind of lithium / sodium ion battery anode material Fe 1-x The preparation method of S / C comprises steps as follows:

[0054] Take 10mL of sulfur-containing petroleum sewage into a three-necked flask, add 0.5ml of 15wt℅ peracetic acid aqueous solution, and stir at 40°C for 40min to obtain pretreated sulfur-containing petroleum sewage; then add 40mL of 0.1mol L -1 The ferric nitrate aqueous solution is slowly added dropwise to the above-mentioned pretreated sulfur-containing petroleum sewage, continuously stirred and added 2ml 2wt℅ citric acid aqueous solution to make the pH value to 2, and stirred at room temperature for 2 hours to obtain a uniform mixed solution; Put it into the reaction kettle, hydrothermally treat it at 150°C for 48 hours, then cool it naturally to room temperature, and dry the precipitate obtained by centrifugation at 60°C to obtain a black powder; wash the black powder twice with water and once with ethanol, and dry at 100°C Dry for 2 hours, and t...

Embodiment 3

[0057] A kind of lithium / sodium ion battery anode material Fe 1-x The preparation method of S / C comprises steps as follows:

[0058] Take 10mL of sulfur-containing petroleum sewage into a three-necked flask, add 2ml of 15wt℅ ammonium persulfate aqueous solution, and stir at 60°C for 20min to obtain pretreated sulfur-containing petroleum sewage; then add 25mL of 0.1mol L -1 The ferric chloride aqueous solution is slowly added dropwise to the above-mentioned pretreated sulfur-containing petroleum sewage, stirring continuously and adding 2ml 2wt℅ glycine acid aqueous solution to make the pH value to 5, stirring at room temperature for 2 hours to obtain a uniform mixed solution; the mixed solution Put it into a reaction kettle, heat it at 220°C for 10 hours, cool it down to room temperature naturally, and dry the precipitate at 60°C after centrifugation to obtain a black powder; wash the black powder twice with water and once with ethanol, and then dry it at 100°C Dry for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com