Graphene foam-nickel oxide composite electrode material and preparation method thereof

A technology of graphene foam and composite materials, which is applied in the field of lithium-ion batteries, can solve the problems of easy agglomeration, pulverization and volume expansion, and poor conductivity of metal oxides, so as to increase the contact area, accelerate the conductivity, and make the preparation process environmentally friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of graphene foam

[0031] Depositing graphene on nickel foam by chemical vapor deposition method: Place the nickel foam (1 cm × 1 cm) in a tube furnace while passing CH 4 , H 2 Mix gas with Ar (volume ratio 1:16:40), then heat up to 1000°C at a rate of 5°C / min, hold for 30 minutes, and then cool to room temperature at a rate of 100°C / min to obtain graphene-coated Foam nickel. The prepared product is placed in a mixed solution of ferric chloride (1.5 mol / L) and hydrochloric acid (hydrochloric acid mass fraction is 5%), soaked for 12 h, then taken out, washed with deionized water and dried to obtain graphene foam .

[0032] 2) Preparation of graphene foam-nickel-based metal organic framework composite material

[0033] Using water / ethanol / N,N-dimethylformamide (volume ratio 1:1:1) as a solvent, nickel chloride (0.31 g), trimesic acid (0.15 g) and polyvinylpyrrolidone (1.50 g) 15 mL of the mixed solution of ), and then placed in a 50 mL stainless steel reactor t...

Embodiment 2

[0037] 1) Preparation of graphene foam

[0038] Depositing graphene on nickel foam by chemical vapor deposition: Place the nickel foam (1 cm × 1 cm) in a tube furnace, and simultaneously pass CH4, H2 and Ar mixed gas (volume ratio 1:16:40) , And then heated to 1100 ℃ at a rate of 5 ℃ / min, kept for 20 min, and then cooled to room temperature at a rate of 100 ℃ / min to obtain graphene-coated nickel foam. The prepared product is placed in a mixed solution of ferric chloride (1.0 mol / L) and hydrochloric acid (hydrochloric acid mass fraction is 5%), soaked for 18 hours, then taken out, washed with deionized water and dried to obtain graphene foam .

[0039] 2) Preparation of graphene foam-nickel-based metal organic framework composite material

[0040] Using water / ethanol / N,N-dimethylformamide (volume ratio 1:1:1) as solvents, nickel nitrate (0.43 g), trimesic acid (0.15 g) and polyvinylpyrrolidone (1.50 g) were prepared Put 20 mL of the mixed solution of the mixture with graphene foam ...

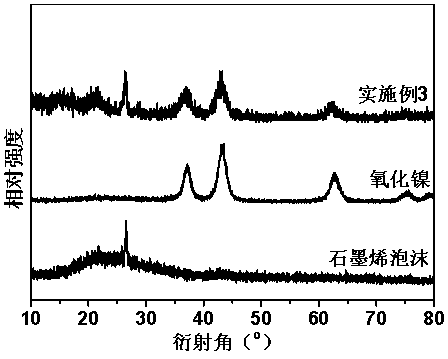

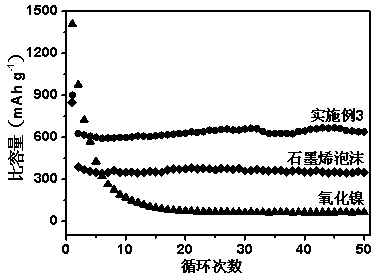

Embodiment 3

[0044] 1) Preparation of graphene foam

[0045] Depositing graphene on nickel foam by chemical vapor deposition: Place the nickel foam (1 cm × 1 cm) in a tube furnace, and simultaneously pass CH4, H2 and Ar mixed gas (volume ratio 1:16:40) , And then heated to 1100 ℃ at a rate of 5 ℃ / min, kept for 20 min, and then cooled to room temperature at a rate of 100 ℃ / min to obtain graphene-coated nickel foam. The prepared product is placed in a mixed solution of ferric chloride (1.0 mol / L) and hydrochloric acid (hydrochloric acid mass fraction is 5%), soaked for 18 hours, then taken out, washed with deionized water and dried to obtain graphene foam .

[0046] 2) Preparation of graphene foam-nickel-based metal organic framework composite material

[0047] Using water / ethanol / N,N-dimethylformamide (volume ratio 1:1:1) as solvents, nickel nitrate (0.43 g), trimesic acid (0.15 g) and polyvinylpyrrolidone (1.50 g) were prepared 30 mL of the mixed solution, and then placed in a 50 mL stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com