Lithium-sulfur battery positive electrode material and preparation method thereof

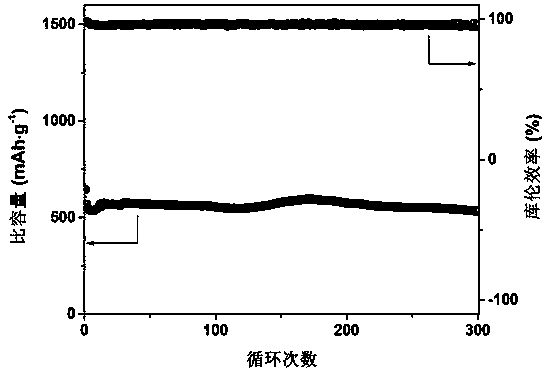

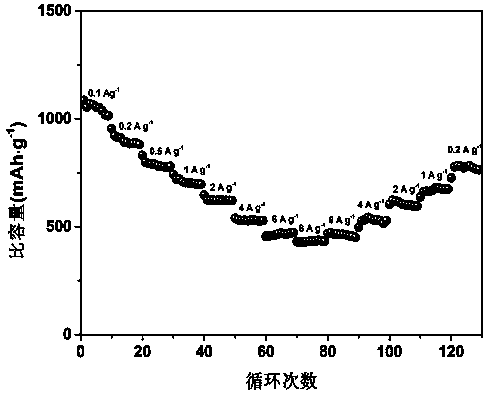

A technology for lithium-sulfur batteries and positive electrode materials, which is applied to battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of cumbersome preparation process, and achieve the effects of simplifying the process, reducing pollution, and stabilizing cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

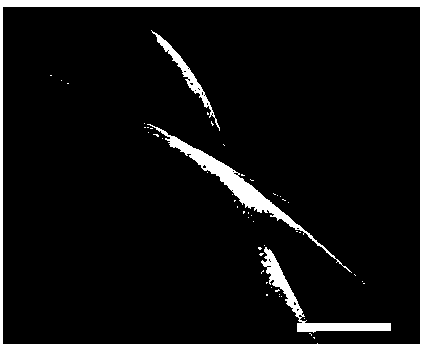

[0045] A lithium-sulfur battery cathode material, specifically prepared by a method comprising the following steps:

[0046] (1) Take 3 ml of N,N-dimethylformamide in a clean glass bottle, then weigh 0.3 g of polyacrylonitrile with a molecular weight of 150,000 as a solute, pour it into the above glass bottle, and place it on a stirring table Stir at a stirring speed of 600r / min for 12h to obtain a polyacrylonitrile solution;

[0047] (2) Take two glass bottles, A and B, and add 1.5ml of the polyacrylonitrile solution obtained in step (1) to each;

[0048] A bottle of polyacrylonitrile solution continued to stir at a stirring speed of 600r / min for 12h;

[0049] Add 0.015 g of copper nitrate to the polyacrylonitrile solution in bottle B, then place it on a stirring table and continue stirring for 12 hours at a stirring speed of 600 r / min until the copper nitrate is dissolved and dispersed evenly to obtain a spinning solution;

[0050] (3) Pour the bottle A of polyacrylonitril...

Embodiment 2

[0067] A lithium-sulfur battery cathode material, specifically prepared by a method comprising the following steps:

[0068] (1) Take 3ml of N,N-dimethylacetamide in a clean glass bottle, then weigh 0.3g of polyacrylonitrile with a molecular weight of 150,000 as a solute, pour it into the above glass bottle, and place it on a stirring table Stir at a stirring speed of 600r / min for 12h, and prepare a polyacrylonitrile solution;

[0069] (2) Take two glass bottles, A and B, and add 1.5ml of the polyacrylonitrile solution prepared in step (1) to each;

[0070] A bottle of polyacrylonitrile solution continued to stir at a stirring speed of 600r / min for 12h;

[0071] Add 0.015 g of cobalt acetate into the polyacrylonitrile solution in bottle B, then place it on a stirring table and continue stirring for 12 hours at a stirring speed of 600 r / min until the cobalt acetate is dissolved and dispersed evenly to obtain a spinning solution;

[0072] (3) Pour the bottle A of polyacrylonit...

Embodiment 3

[0084] A lithium-sulfur battery cathode material, specifically prepared by a method comprising the following steps:

[0085] (1) Put 3 ml of absolute ethanol in a clean glass bottle, weigh 0.3 g of polyvinylpyrrolidone with a molecular weight of 1,300,000 as a solute, pour it into the above glass bottle, and place it on a stirring table with 600r / min stirring Stir at a high speed for 12 hours to obtain a polyvinylpyrrolidone solution;

[0086] (2) Take two glass bottles, A and B, and add 1.5ml of the polyvinylpyrrolidone solution prepared in step (1) to each;

[0087] A bottle of polyvinylpyrrolidone solution continued to stir at a stirring speed of 600r / min for 12h;

[0088] Add nickel nitrate with a mass of 0.015 g to the polyvinylpyrrolidone solution in bottle B, then place it on a stirring table and continue stirring for 12 hours at a stirring speed of 600 r / min until the nickel nitrate is dissolved and dispersed evenly to obtain a spinning solution;

[0089] (3) Pour th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com