Visible-light response Ag/Bi3O4Cl composite material as well as preparation method and application thereof

A composite material and visible light technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, light water/sewage treatment, etc., can solve the problem of poor separation efficiency of photogenerated electrons and holes, unsatisfactory photocatalytic activity and visible light utilization efficiency. Degradability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

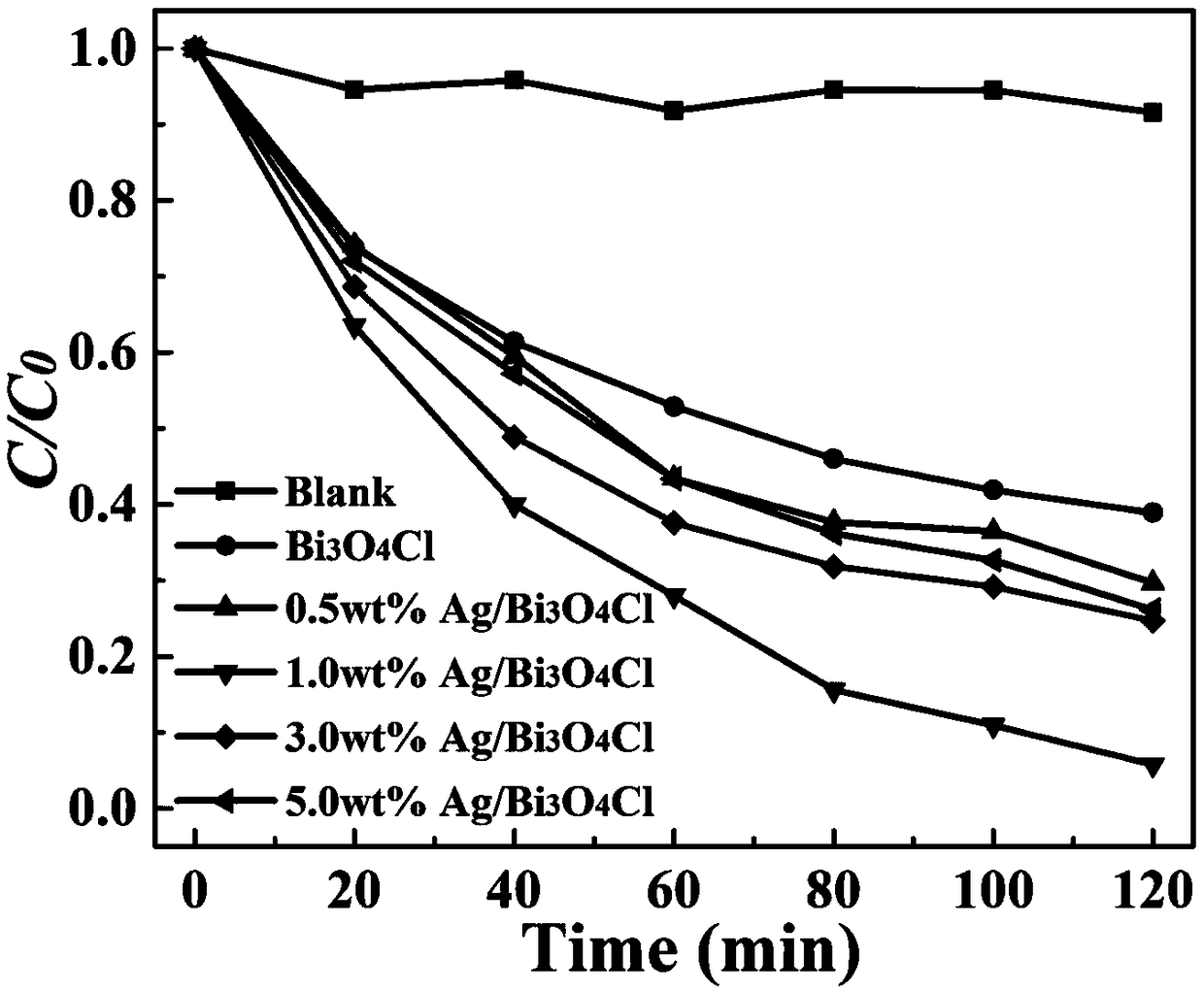

Embodiment 1

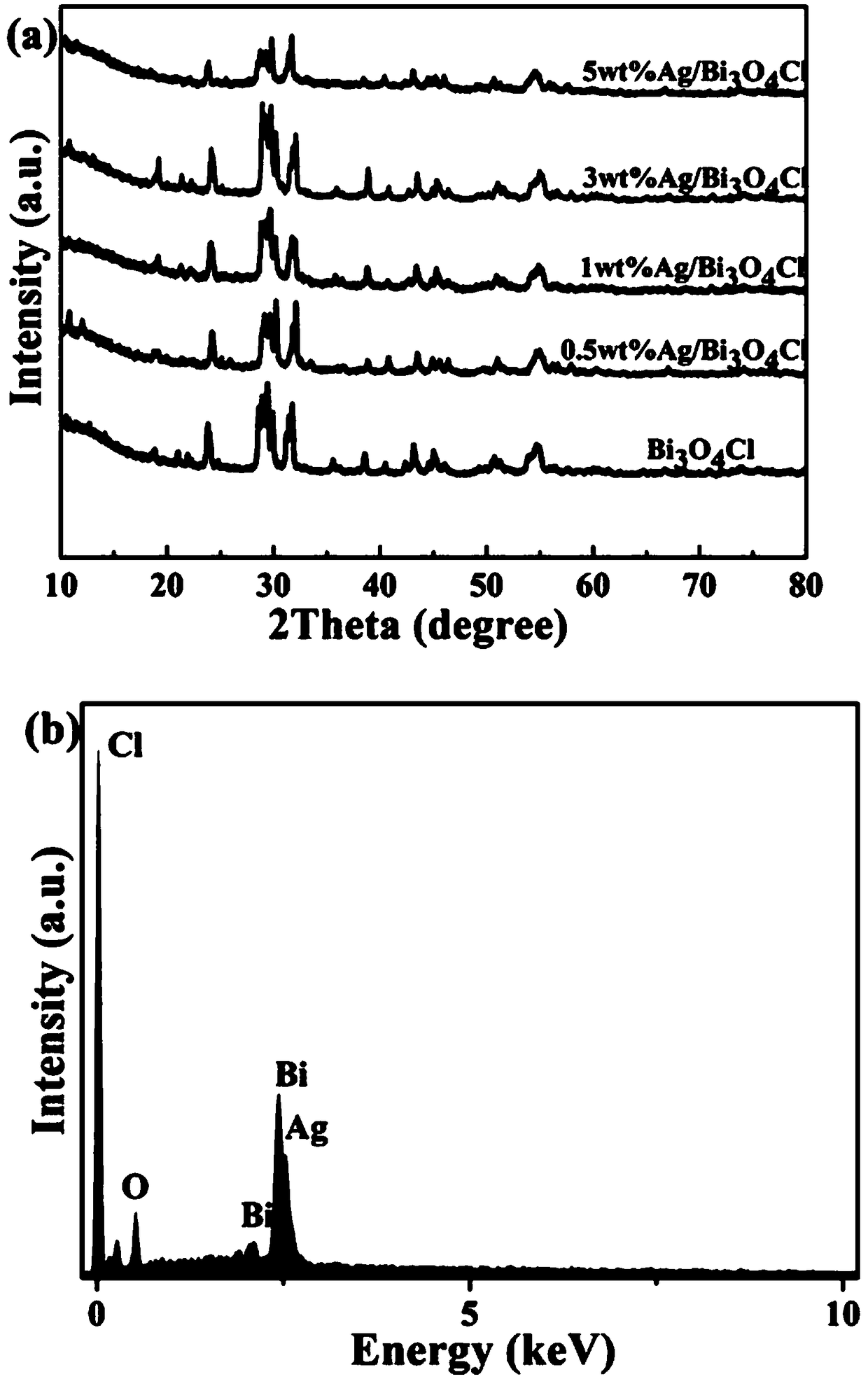

[0020] Step 1: Bi 3 o 4 Preparation of Cl nanosheets

[0021] First, 0.485g Bi(NO 3 ) 3 ·5H 2 O was ultrasonically dispersed in 10 mL of ethylene glycol and stirred for 10 min to obtain solution A. Next, add 0.018g NH 4 Dissolve Cl in 25mL deionized water to obtain solution B. Slowly add solution B to the above solution A to form a white turbid solution, transfer it to a 50mL reaction kettle, and heat at 160°C for 12h. After the reactor was cooled to room temperature, the sample was washed with water and ethanol, and dried to obtain solid powder C. Finally, the solid powder C was calcined in a muffle furnace at 500°C for 5h at a heating rate of 5°C / min. Finally got Bi 3 o 4 Cl nanosheets.

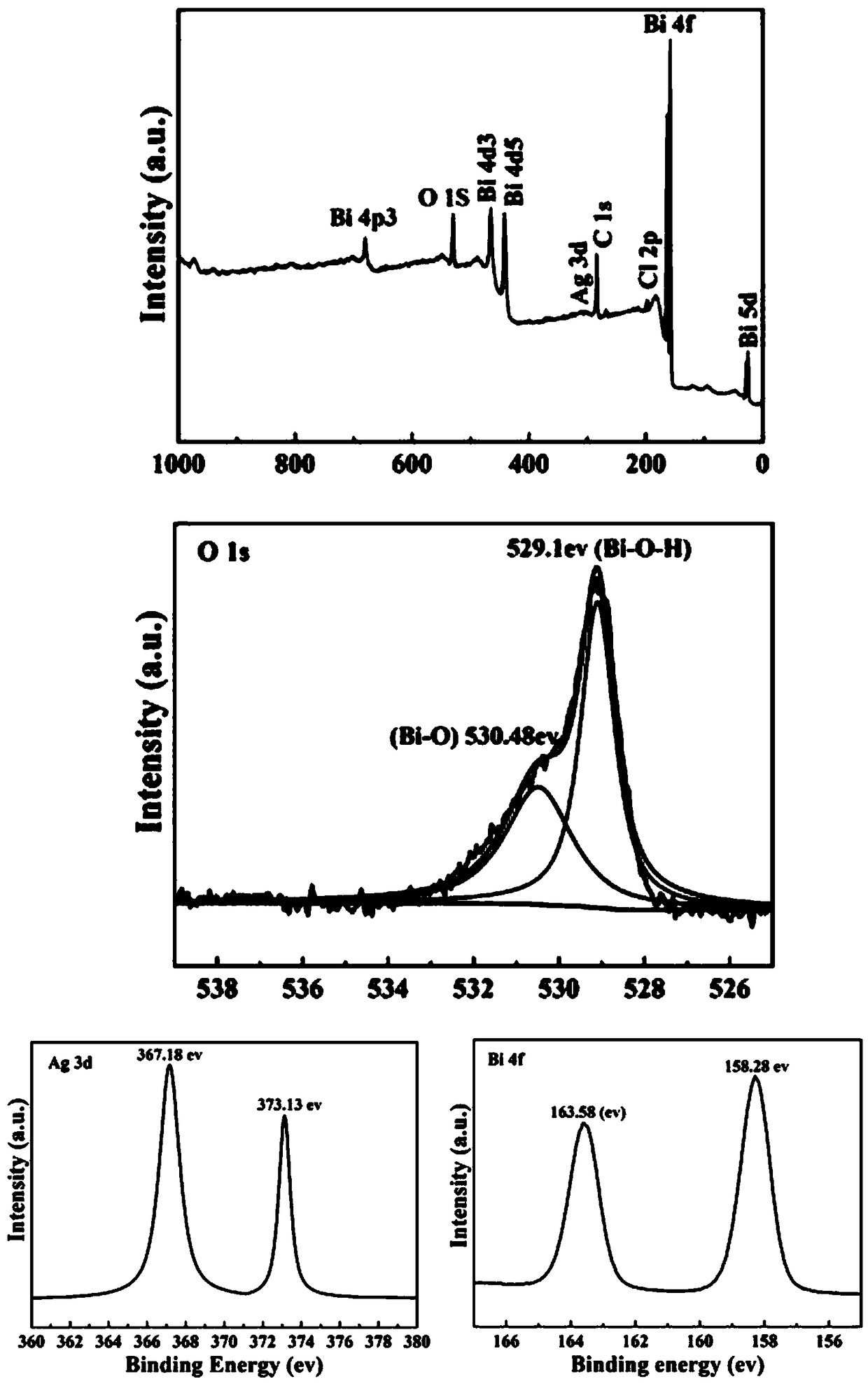

[0022] Step 2: Ag / Bi 3 o 4 Preparation of Cl composites

[0023] Bi 3 o 4 Cl dissolved in AgNO 3 After stirring evenly in the solution, irradiate with 250W xenon lamp for 60min, wash with water and dry to obtain Ag / Bi 3 o 4 Cl composites.

[0024] Further, Bi 3 o 4 Cl a...

Embodiment 2

[0029] Step 1: Bi 3 o 4 Preparation of Cl nanosheets

[0030] First, 0.485g Bi(NO 3 ) 3 ·5H 2 O was ultrasonically dispersed in 10 mL of ethylene glycol and stirred for 10 min to obtain solution A. Next, add 0.018g NH 4 Dissolve Cl in 25mL deionized water to obtain solution B. Slowly add solution B to the above solution A to form a white turbid solution, transfer it to a 50mL reaction kettle, and heat at 160°C for 12h. After the reactor was cooled to room temperature, the sample was washed with water and ethanol, and dried to obtain solid powder C. Finally, the solid powder C was calcined in a muffle furnace at 500°C for 5h at a heating rate of 5°C / min. Finally got Bi 3 o 4 Cl nanosheets.

[0031] Step 2: Ag / Bi 3 o 4 Preparation of Cl composites

[0032] Bi 3 o 4 Cl dissolved in AgNO 3 After stirring evenly in the solution, irradiate with 250W xenon lamp for 60min, wash with water and dry to obtain Ag / Bi 3 o 4 Cl composites.

[0033] Further, Bi 3 o 4 Cl a...

Embodiment 3

[0038] Step 1: Bi 3 o 4 Preparation of Cl nanosheets

[0039] First, 0.485g Bi(NO 3 ) 3 ·5H 2 O was ultrasonically dispersed in 10 mL of ethylene glycol and stirred for 10 min to obtain solution A. Next, add 0.018g NH 4 Dissolve Cl in 25mL deionized water to obtain solution B. Slowly add solution B to the above solution A to form a white turbid solution, transfer it to a 50mL reaction kettle, and heat at 160°C for 12h. After the reactor was cooled to room temperature, the sample was washed with water and ethanol, and dried to obtain solid powder C. Finally, the solid powder C was calcined in a muffle furnace at 500°C for 5h at a heating rate of 5°C / min. Finally got Bi 3 o 4 Cl nanosheets.

[0040] Step 2: Ag / Bi 3 o 4 Preparation of Cl composites

[0041] Bi 3 o 4 Cl dissolved in AgNO 3 After stirring evenly in the solution, irradiate with 250W xenon lamp for 60min, wash with water and dry to obtain Ag / Bi 3 o 4 Cl composites.

[0042] Further, Bi 3 o 4 Cl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com