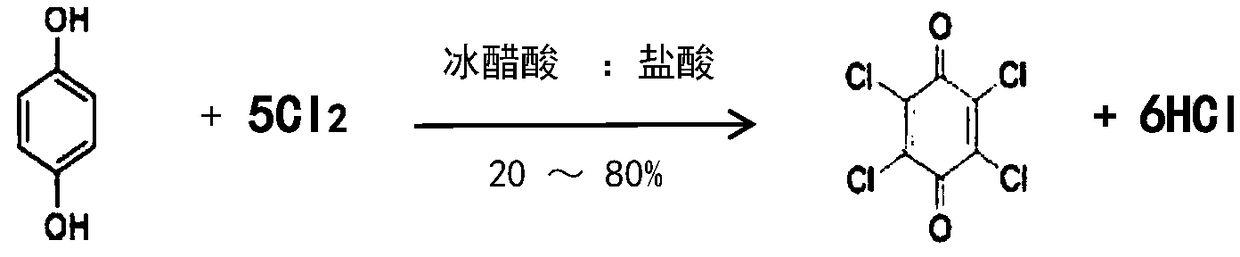

Method for reducing dioxin in preparation of chloranil

A technology of chloranil and chlorine gas, which is applied in the field of dioxin reduction in the preparation of chloranil, can solve the problems of low dioxin content, high production cost and waste water treatment cost, and can not be achieved, and achieves simple preparation process , High production efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 01

[0027] [Example 01] Mix 600g of glacial acetic acid, 200g of 35% hydrochloric acid, and 30g of ammonium chloride with a 1000ml glass reactor, heat up to 70°C and keep for 10 minutes to filter to obtain mother liquor M0.3-00; 45g of hydroquinone, 20g of p-aminophenol, and mother liquor M0.3-00 were stirred and mixed, and when the temperature was raised to 70°C, the chlorine flow (80g / hour) was passed, and after 3.5 hours, the chlorine flow was stopped, and the temperature was raised to 85°C for filtration: to obtain the mother liquor M0.3 -01 counts 710g and chloranil 141.5g of washing and drying.

example 02

[0028] [Example 02] Stir and mix the mother liquor M0.3-01+25% hydrochloric acid 90g, hydroquinone 50g, and p-aminophenol 15g, and introduce chlorine gas (80g / hour) when the temperature is raised to 80°C, stop the chlorine flow after 3.5 hours, Raise the temperature to 90° C. and filter: 680 g of mother liquor M0.3-02 and 141.2 g of chloranil were washed and dried.

example 03

[0029] [Example 03] Mix the mother liquor M0.3-02+120g of 15% hydrochloric acid, 60g of hydroquinone, and 5g of p-aminophenol, stir and mix and introduce chlorine gas (80g / hour) when the temperature is raised to 85°C, stop the chlorine flow for 3.5 hours, Raise the temperature to 95° C. and filter: 690 g of mother liquor M0.3-03 and 139.6 g of chloranil were washed and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com