A kind of self-extinction photocurable resin, preparation method and application thereof

A light-curing resin and self-dulling technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of matte UV coatings, such as difficult matting, easy damage to the coating surface, poor orientation of matting powder, etc., to achieve matte The effect is uniform, the adhesion is good, and the matting effect is in line with the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

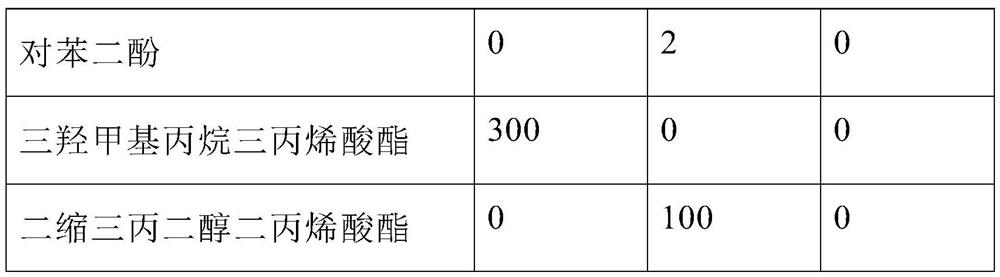

[0062] (1) to a device with a stirrer, a thermometer and a 2 Add 372.9g of TDI monomer 1, 300g of trimethylolpropane triacrylate and 2g of 2,6-di-tert-butyl-4-methylphenol into a protected 1000ml four-neck flask, stir well, heat to 50°C, and slowly add 223.7g hydroxyethyl acrylate; after adding hydroxyethyl acrylate, keep the system temperature at around 50°C;

[0063] (2) When the NCO content of the system is 11%, add 1g of 2,4,6-tris(dimethylaminomethyl)phenol and heat up to 60°C for reaction;

[0064] (3) When the NCO content of the system drops to 3.31%, add 0.4g of benzoyl chloride; heat up to 75°C for reaction, and slowly add 99.6g of hydroxyethyl acrylate;

[0065] (4) When the NCO content of the system drops to 0.41%, add 0.5g of p-hydroxyanisole, stir for 30 minutes, then cool down to 25°C, the product preparation is completed, and the material is discharged. The test viscosity is 1100mPa·s (measured at 60°C), and the platinum cobalt color number is 30.

Embodiment 2

[0067] (1) to a device with a stirrer, a thermometer and a 2 Add 306gTDI monomer 2, 100g tripropylene glycol diacrylate and 5g tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester in the protected 1000ml four-necked flask, stir Evenly, heat to 50°C, slowly add 228.5g hydroxyethyl methacrylate; after adding hydroxyethyl methacrylate, maintain the system temperature at about 55°C;

[0068] (2) When the NCO content of the system is 11.6%, add 0.5g of N,N-dimethylbenzylamine, and heat up to 70°C for reaction;

[0069] (3) When the NCO content of the system drops to 5.8%, add 0.2g of benzoyl chloride; heat up to 80°C for reaction, and slowly add 357.9g of hydroxyethyl methacrylate;

[0070] (4) When the NCO content of the system drops to 0.32%, add 2 g of hydroquinone, stir for 30 minutes, then cool down to 25° C., the product preparation is completed, and the material is discharged. The test viscosity is 230mPa·s (measured at 60°C), and the platinum c...

Embodiment 3

[0072] (1) to a device with a stirrer, a thermometer and a 2 Add 590.8g of TDI monomer 1, 6g of 2,6-di-tert-butyl-4-methylphenol and 2g of triphenyl phosphite into a protected 1000ml four-neck flask, stir well, and heat to 60°C;

[0073] (2) When the NCO content of the system is 48%, add 2g of 2,4,6-tris(dimethylaminomethyl)phenol, and heat up to 65°C for reaction;

[0074] (3) When the NCO content of the system drops to 24%, add 1.5g of phosphoric acid; heat up to 70°C for reaction, and slowly add 393.9g of hydroxyethyl acrylate;

[0075] (4) When the NCO content of the system drops to 0.48%, add 4g of p-hydroxyanisole, stir for 30 minutes, then cool down to 25°C, the product preparation is completed, and the material is discharged. The test viscosity is 3850mPa·s (measured at 60°C), and the platinum cobalt color number is 40.

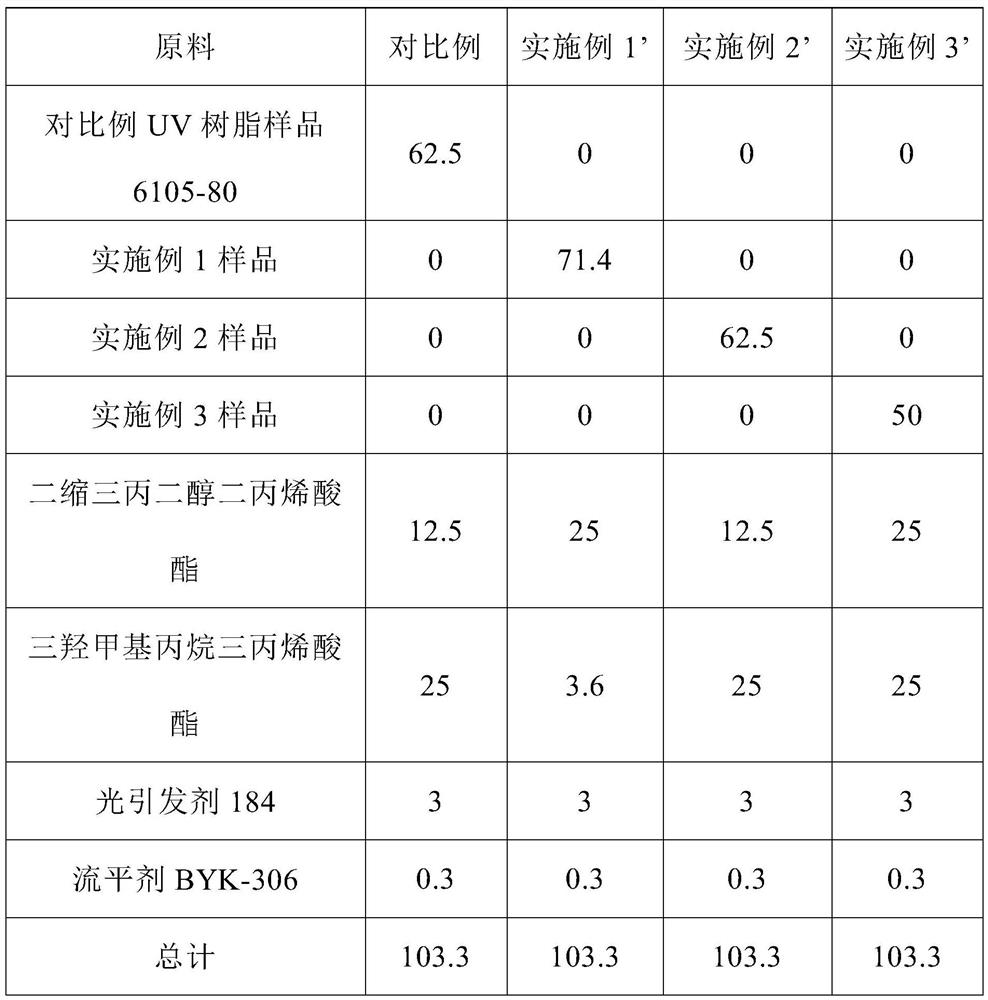

[0076] Preparation of paint film

[0077] According to the formula shown in Table 2, the raw materials of each component were stirred evenly at 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com