A kind of battery electrode and its preparation method and battery

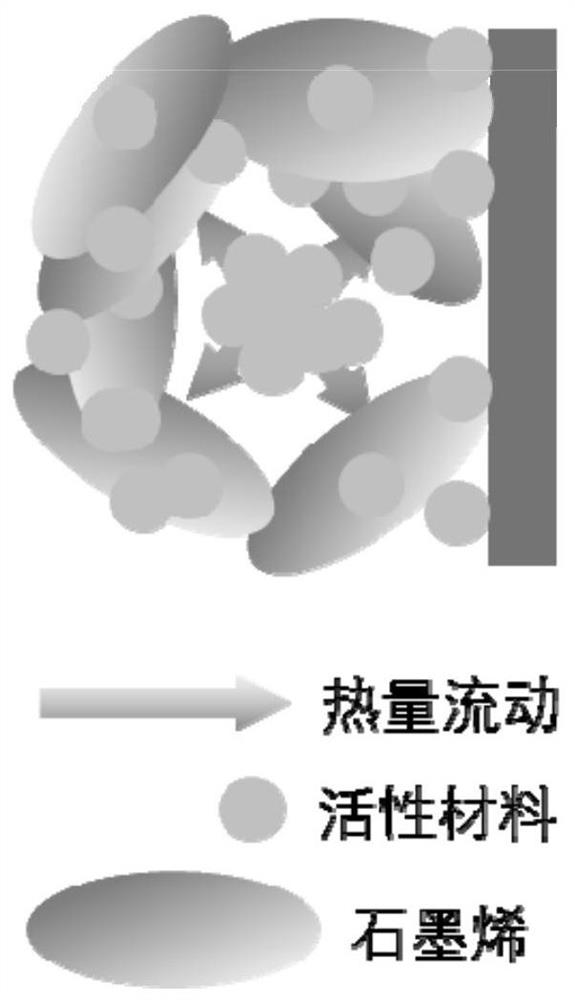

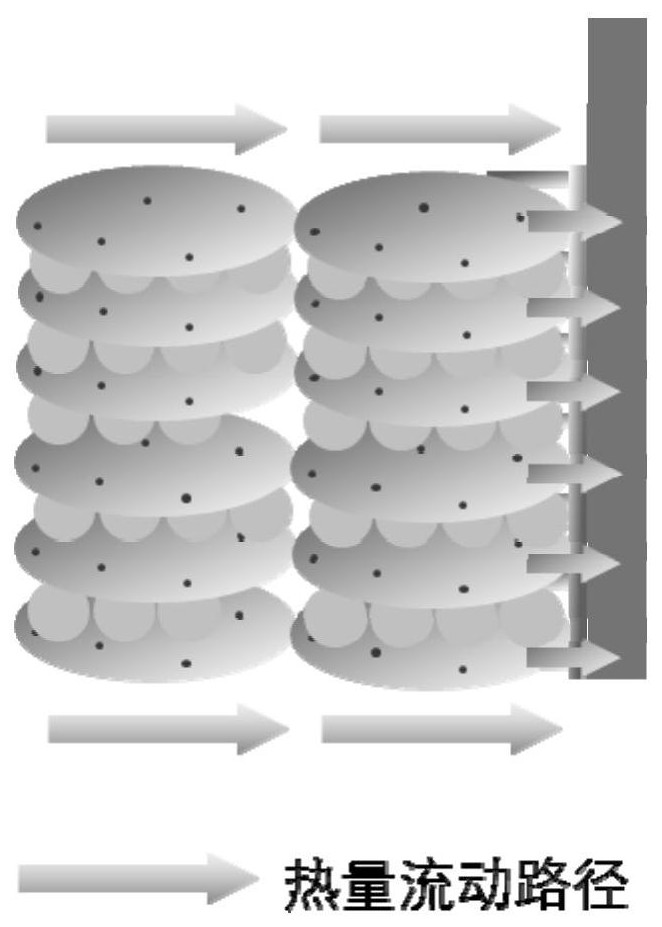

A battery electrode and battery technology, applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, electrode carriers/collectors, etc., can solve the problems of poor high-temperature performance of the battery and the inability to conduct heat from the inside to the environment in time, and achieve uniform dispersion, The effect of reducing fever and avoiding reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

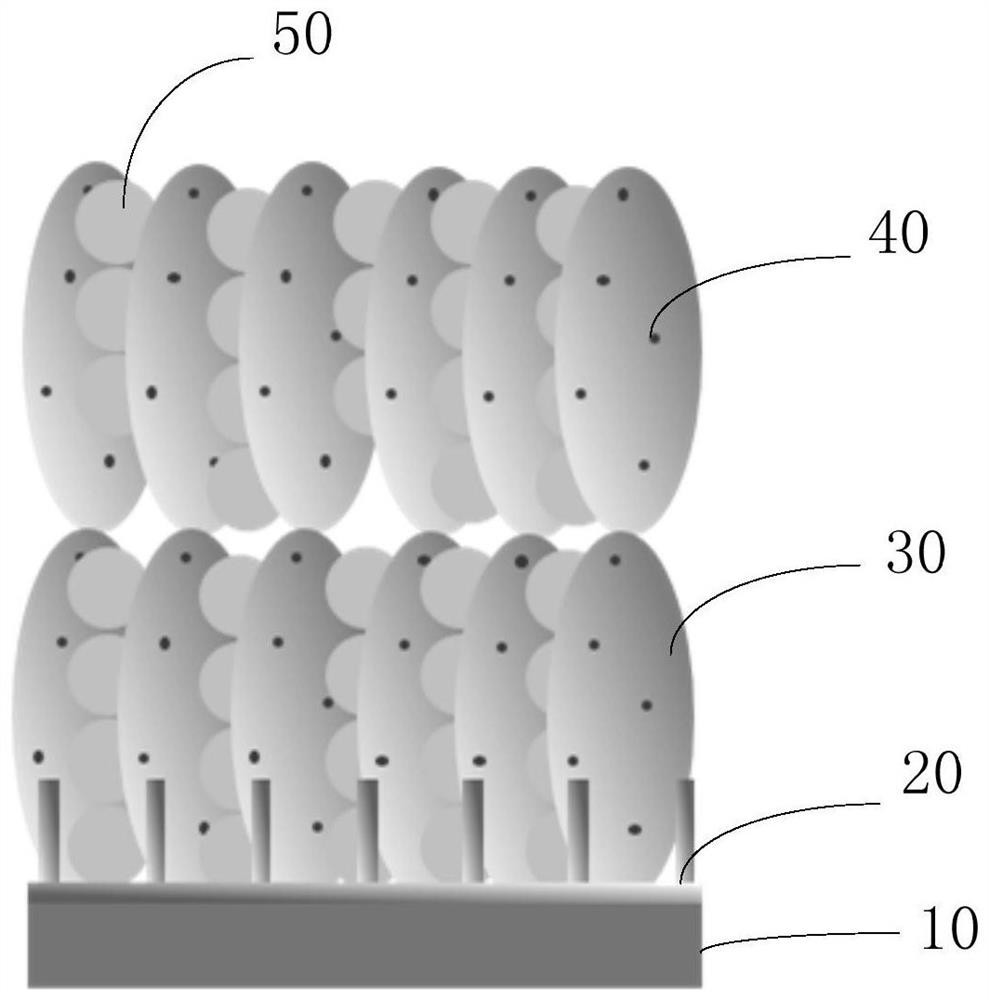

[0060] Correspondingly, an embodiment of the present invention also provides a method for preparing a battery electrode, comprising the following steps:

[0061] (1) A current collector is provided, and a thermally conductive modified layer is prepared on the current collector by a physical coating method, a chemical vapor deposition method, an evaporation deposition method or a sputtering method;

[0062] (2) Take graphene with a sheet-like structure, and prepare graphene surface-modified with magnetically responsive nano-dots by microwave synthesis, hydrothermal method, magnetron sputtering method, evaporation deposition method or chemical vapor deposition method;

[0063] (3) Mix the graphene whose surface is modified with magnetically responsive nano-dots with electrode active materials and binders to obtain a slurry, and apply the slurry evenly on the thermally conductive modification layer under the action of an external magnetic field surface, and dried under the action...

Embodiment 1

[0087] A method for preparing a battery electrode, comprising the following steps:

[0088] (1) Construction of copper current collector with graphene coating on the surface: soak copper foil (99.9% purity) in 1mol / L hydrochloric acid solution for 10 minutes to remove surface impurities, rinse and dry repeatedly with clean water, then place copper foil in N 2 In a protective atmosphere, the temperature was raised to 600° C. within 30 minutes, and 5% (oxygen accounted for the volume fraction of the entire incoming gas flow) trace oxygen was introduced for 1 hour to perform micro-oxidation treatment to form a three-dimensional current collector with CuO nanowire arrays grown on the surface. Then adjust the atmosphere to H 2 / Ar, heat up to 700°C, and introduce 3% methane / Ar mixed gas (3% is the volume fraction of methane in the total gas), cool down to room temperature naturally after reacting for 1h, and obtain a copper current collector with a graphene coating on the surface,...

Embodiment 2

[0095] A method for preparing a battery electrode, comprising the following steps:

[0096] (1) Construction of aluminum-magnesium alloy current collector with graphene coating on the surface: soak the aluminum-magnesium alloy current collector in 0.1mol / L hydrochloric acid solution for 5 minutes to remove impurities on the surface of the current collector, rinse and dry repeatedly with clean water. Then place the aluminum-magnesium alloy current collector in H 2 In the / Ar mixed atmosphere, the temperature was raised from room temperature to 450 °C at a rate of 10 °C / min, and the temperature was kept constant for 1 hour to remove impurity salts that may remain in the current collector. Then the temperature was raised to 700°C at 3°C / min, and 3% acetonitrile / Ar mixed gas was introduced, and the temperature was naturally cooled to room temperature after 1 hour of reaction to obtain an aluminum-magnesium alloy current collector with a graphene coating on the surface;

[0097] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com